Call Us

ZHANJIANG WEIDA

MACHINERY MANUFACTURER

Who We Are: Our Identity

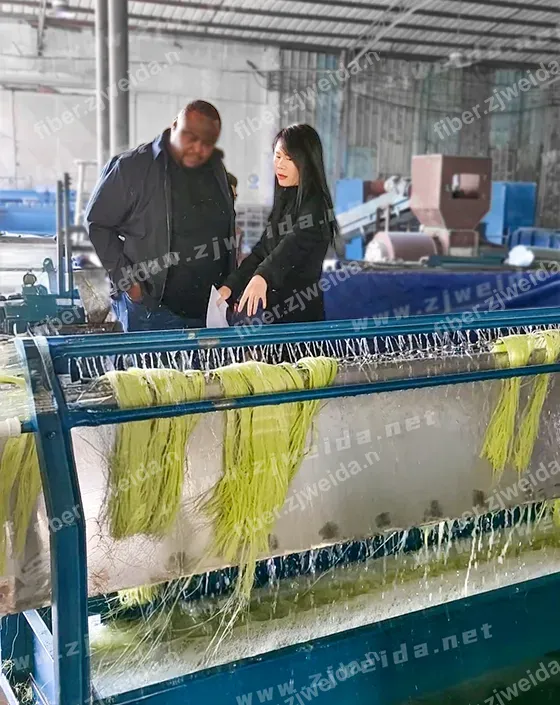

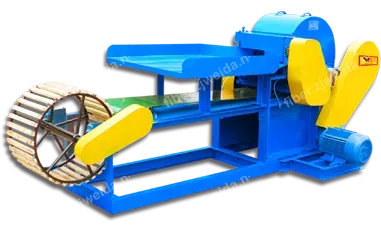

Zhanjiang Weida Machinery Industrial Co., Ltd. (Brand: "WEIJIN"), founded in 2004, is a veteran manufacturing enterprise deeply rooted in the plant fiber processing field for over 20 years. We focus on the R&D and manufacturing of primary processing extraction and deep processing equipment for tropical and subtropical plant fibers, being an important player in China and even the global natural bast and leaf fiber primary processing equipment field.

With excellent quality and service, our business footprint has extended from China to core tropical crop production regions in Southeast Asia, Africa, and Latin America, winning widespread market recognition and stable customer trust.

Since 2004

Brand: WEIJIN

Global Vision

Veteran Manufacturer

Core Business: Full Category Coverage

We are committed to providing global customers with efficient, stable, and eco-friendly one-stop plant fiber processing solutions.

Wide Material Applicability: Covering natural plant fibers such as Sisal, Jute, Pineapple Leaf, Banana Stem, extending to Palm, Coir, and composite fiber recycling.

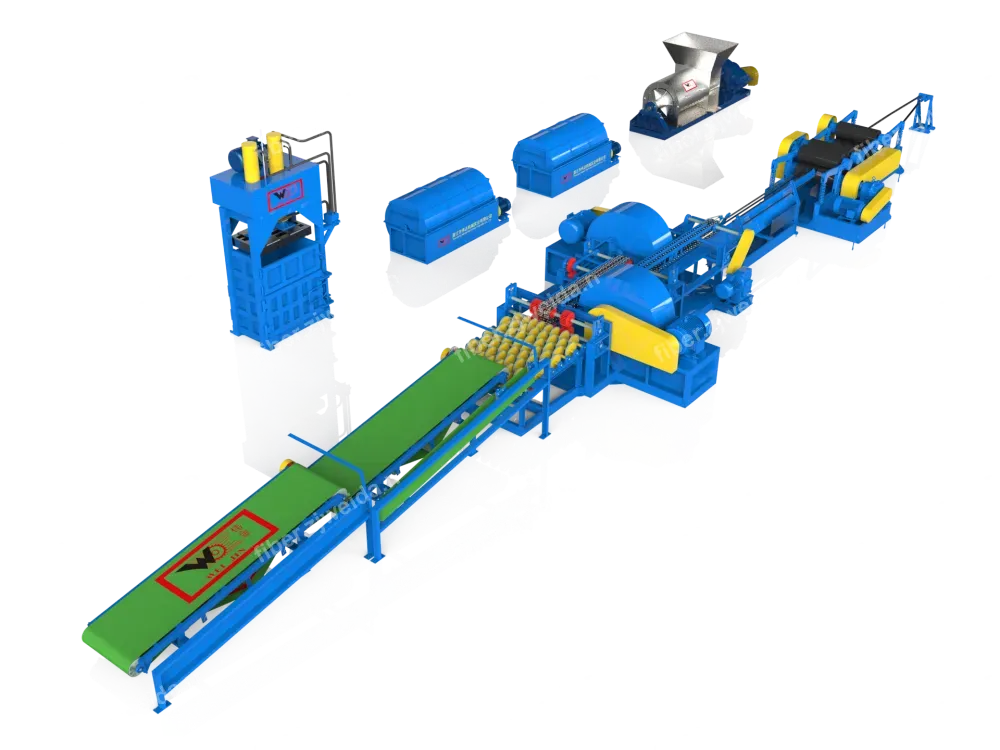

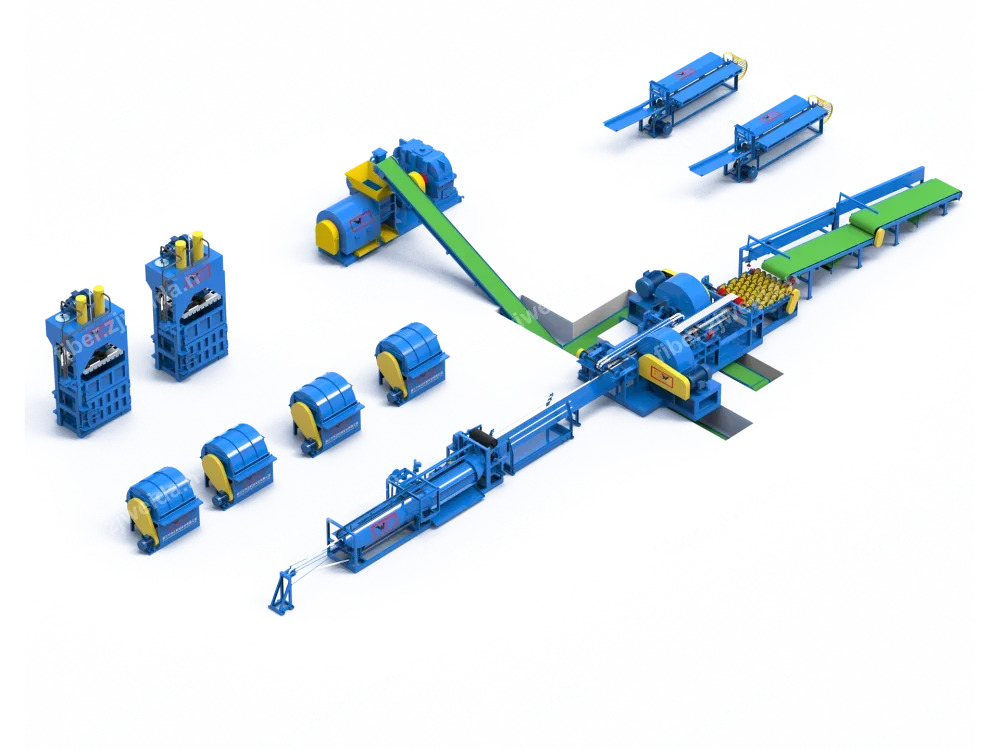

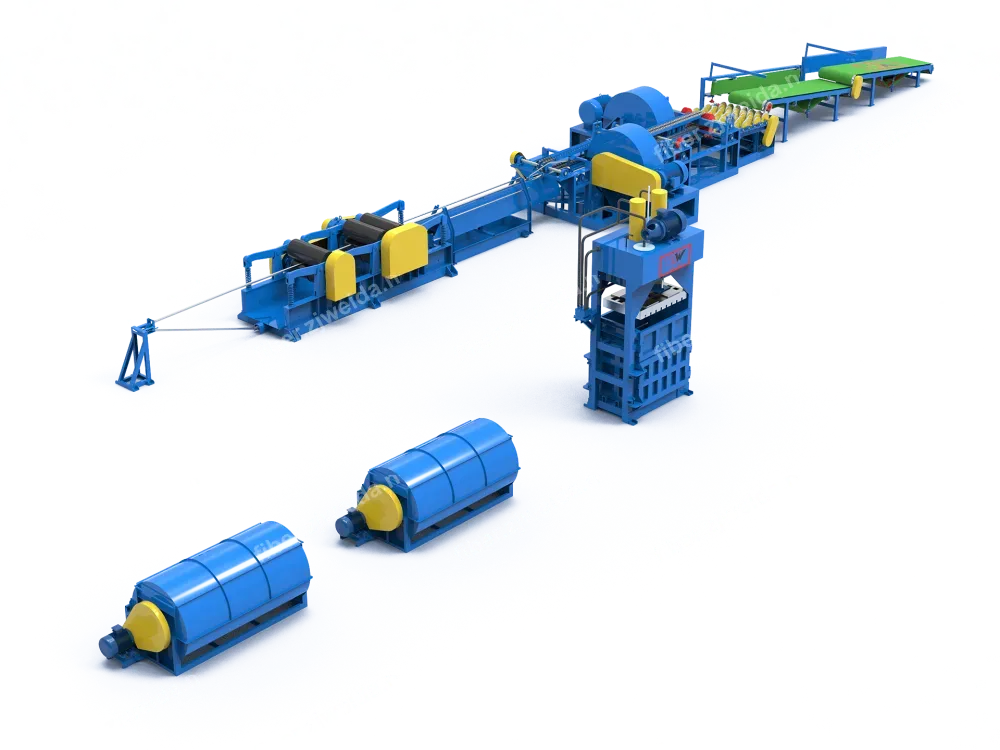

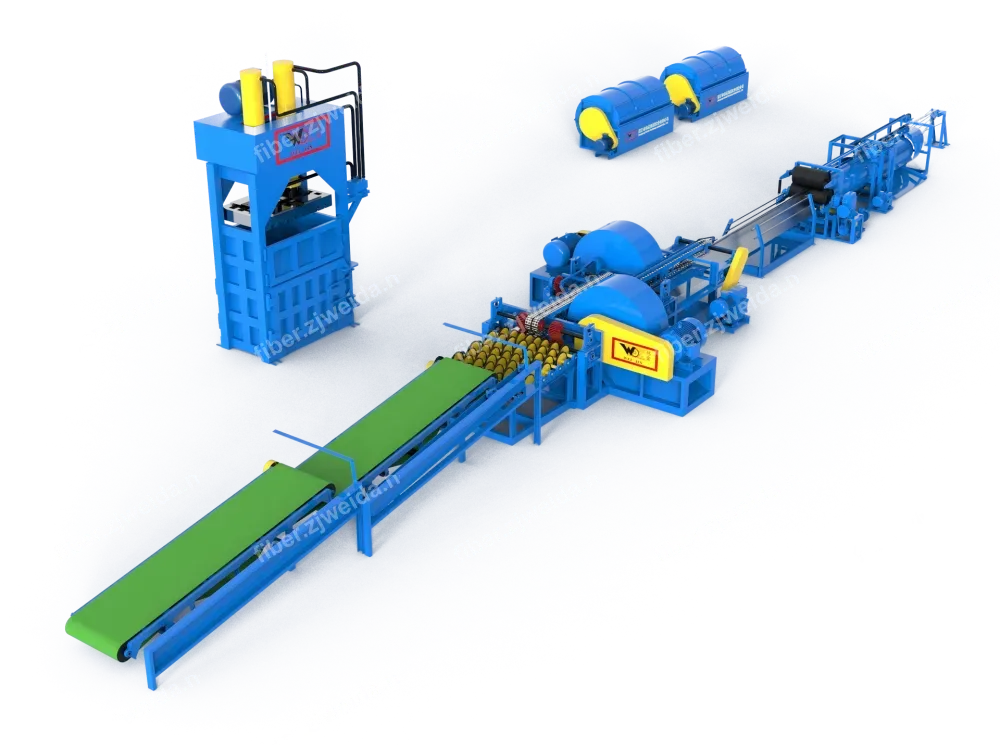

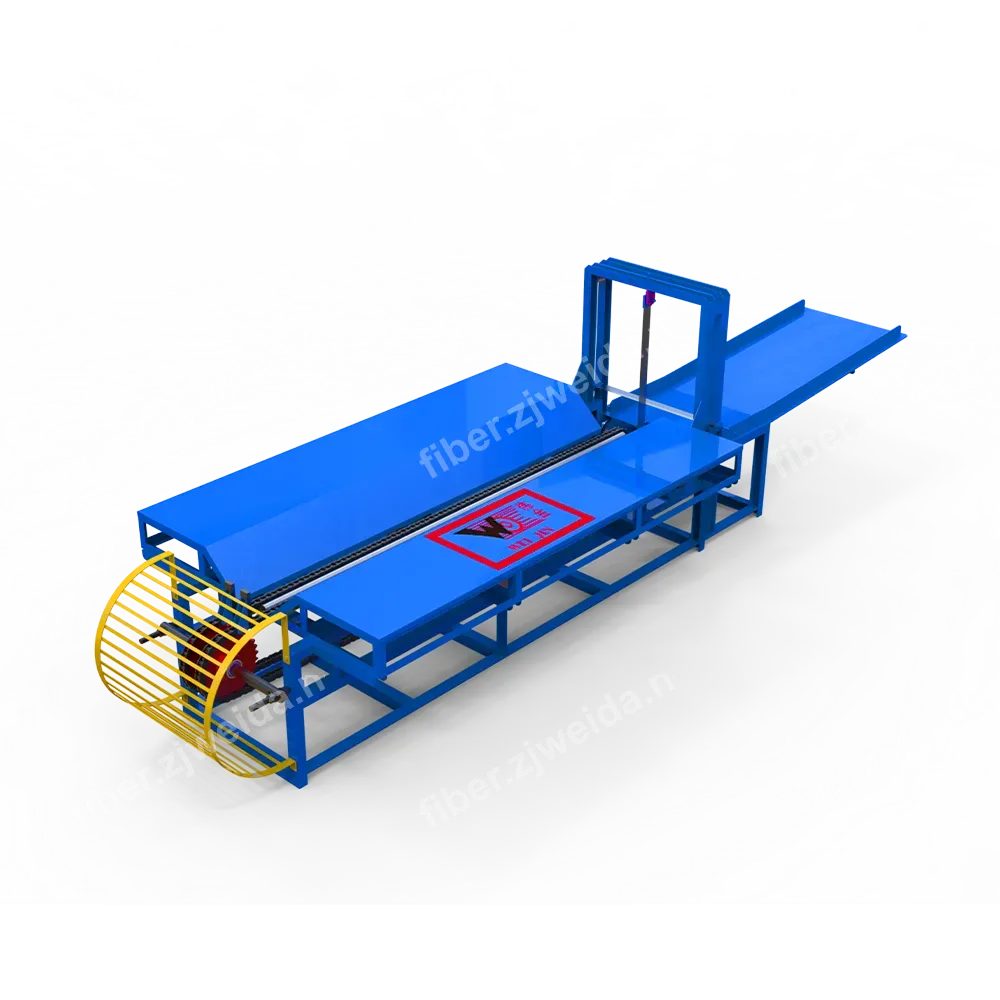

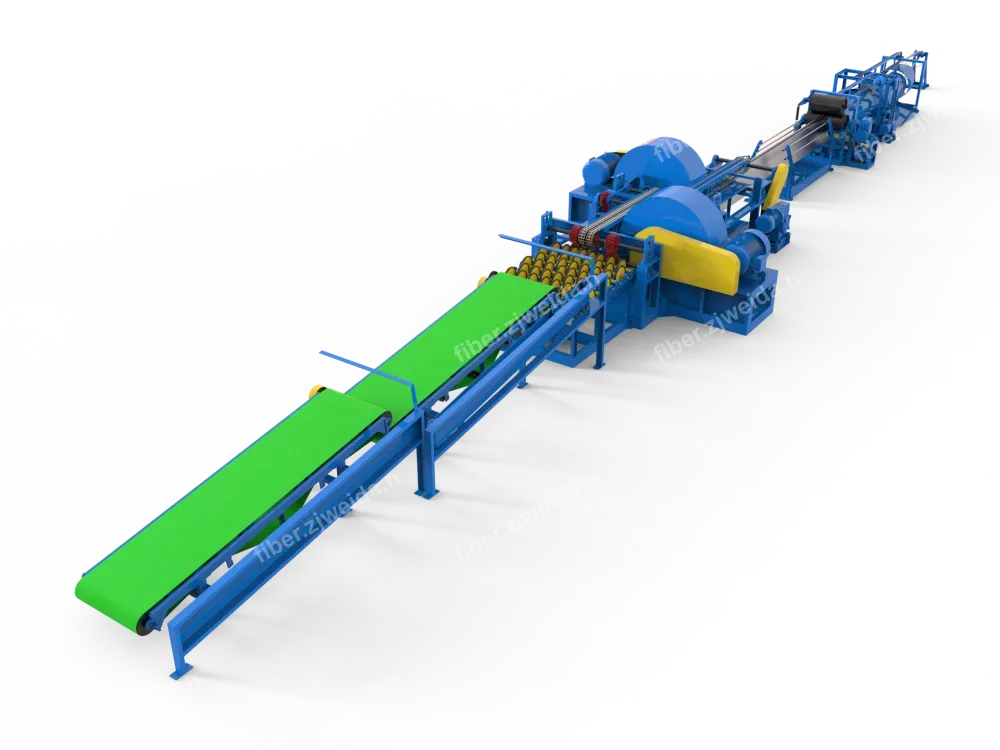

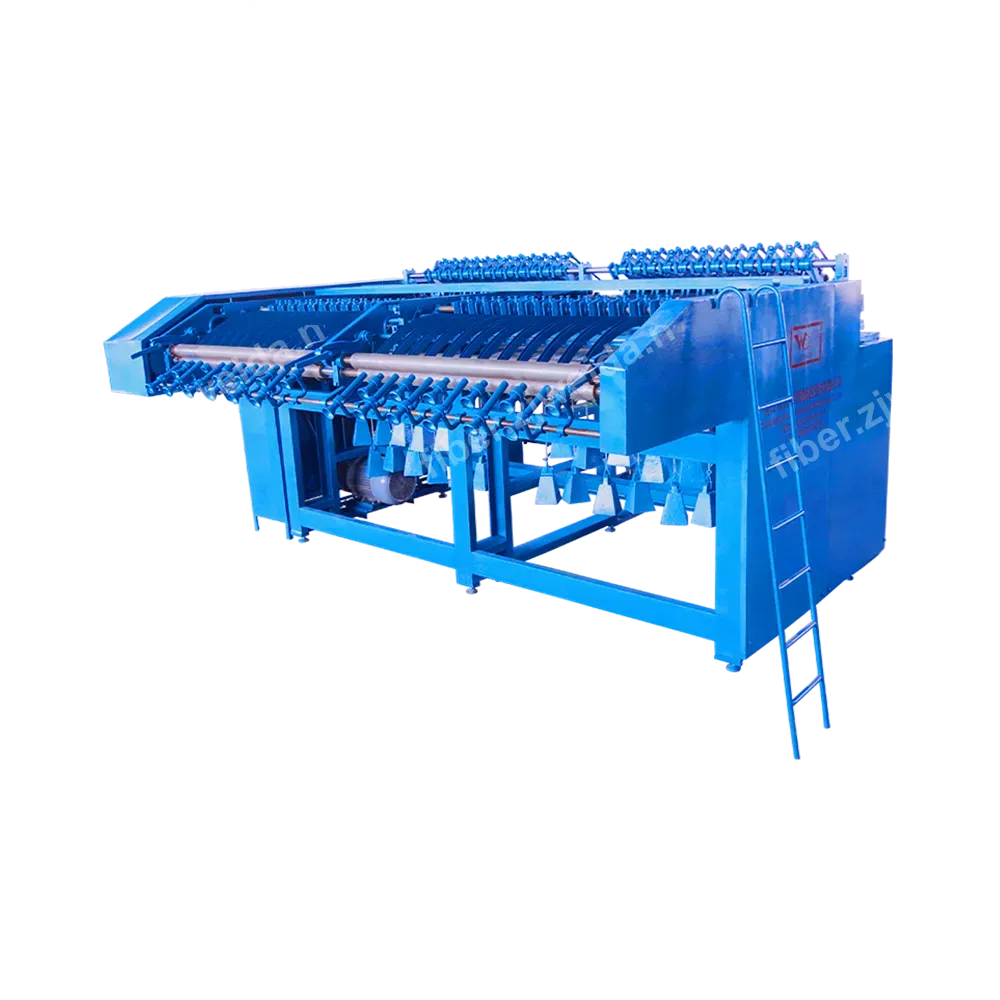

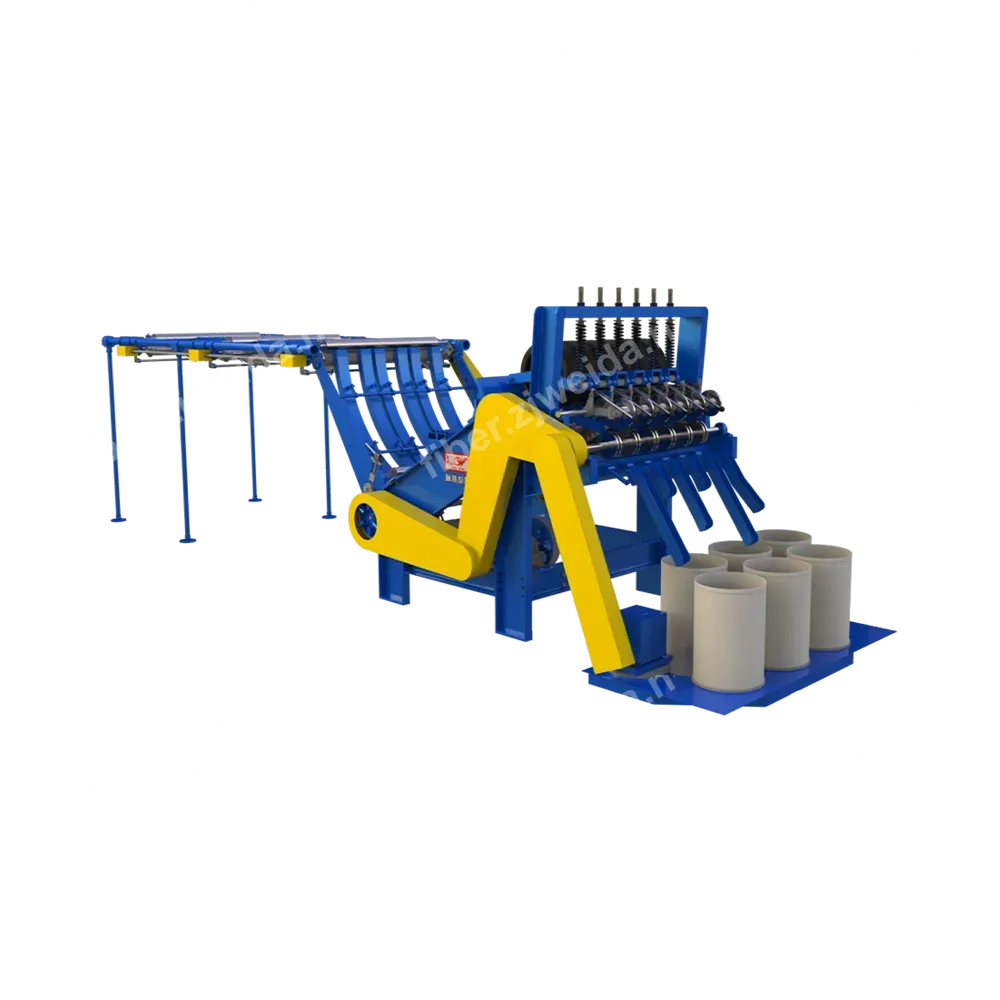

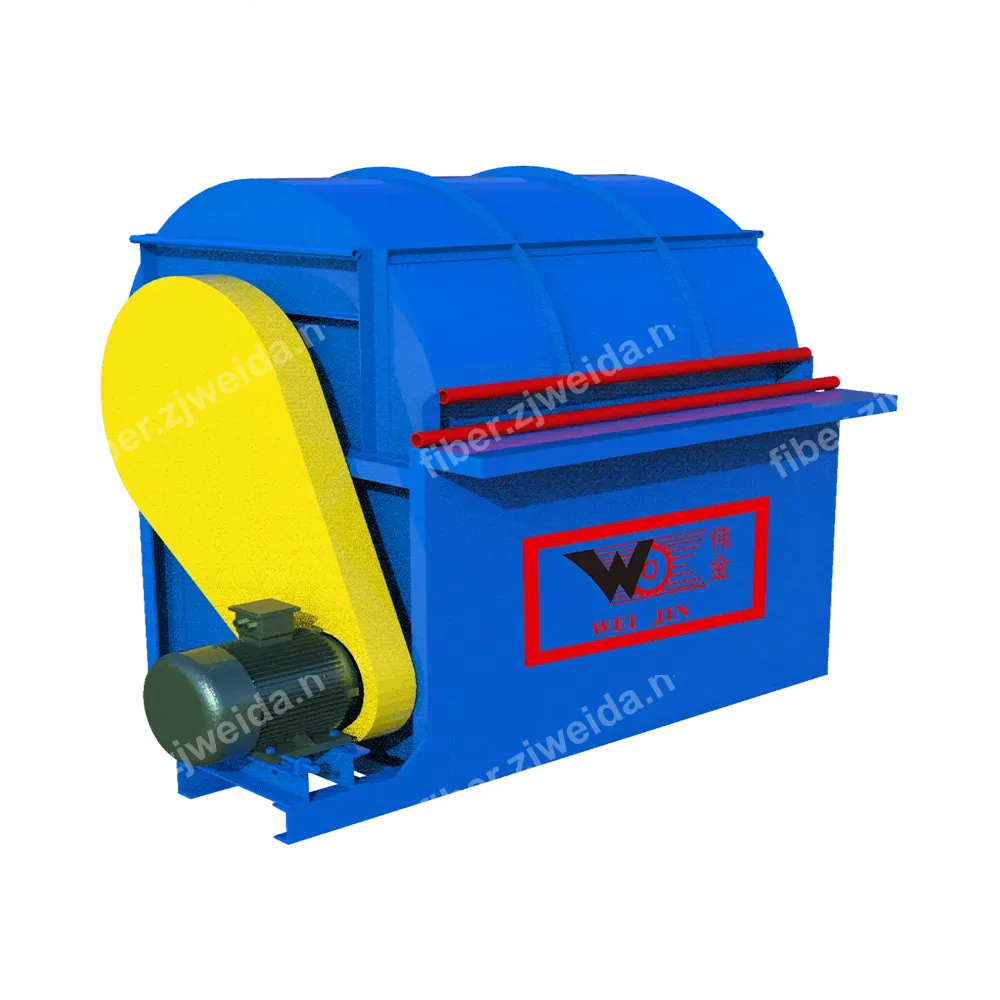

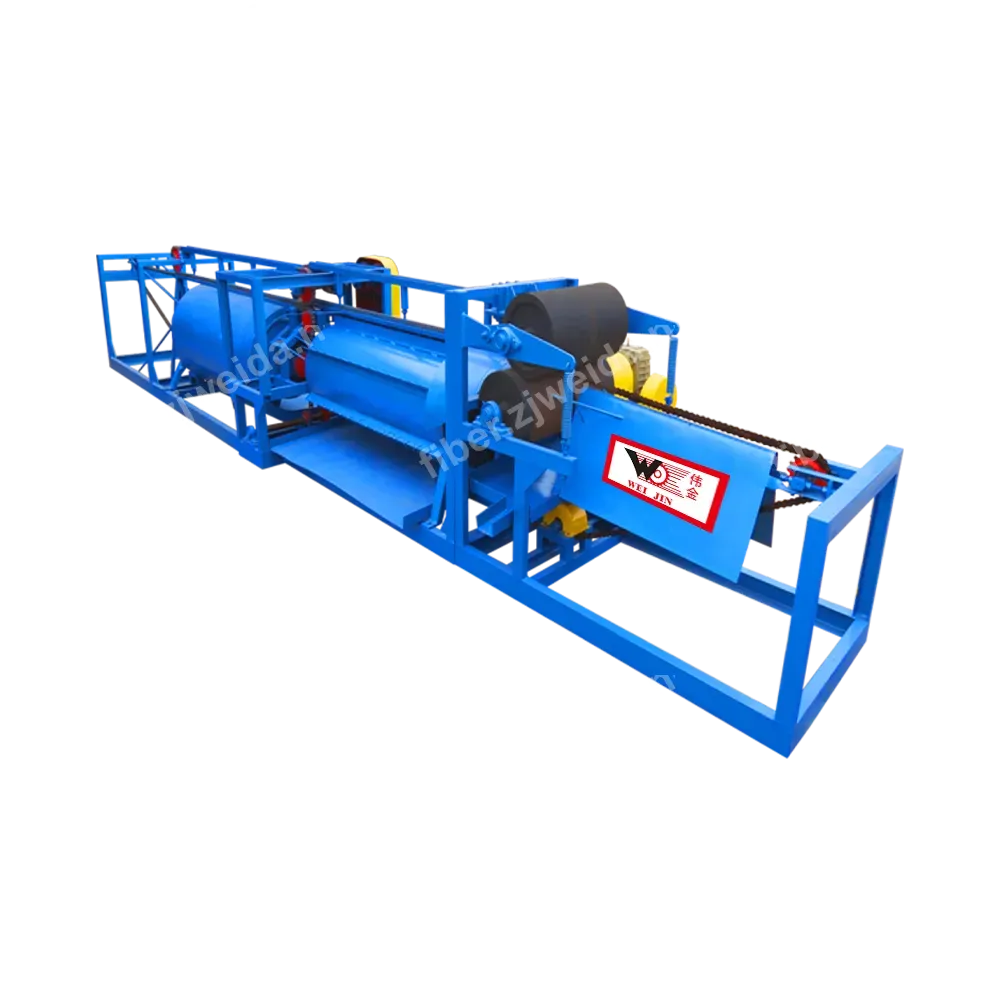

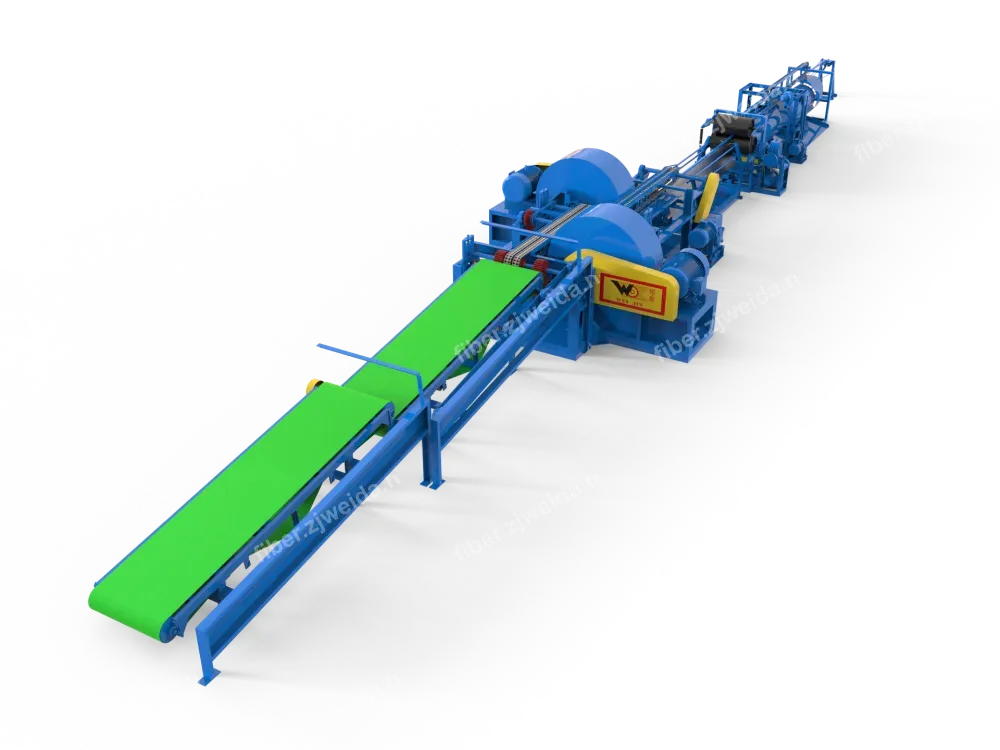

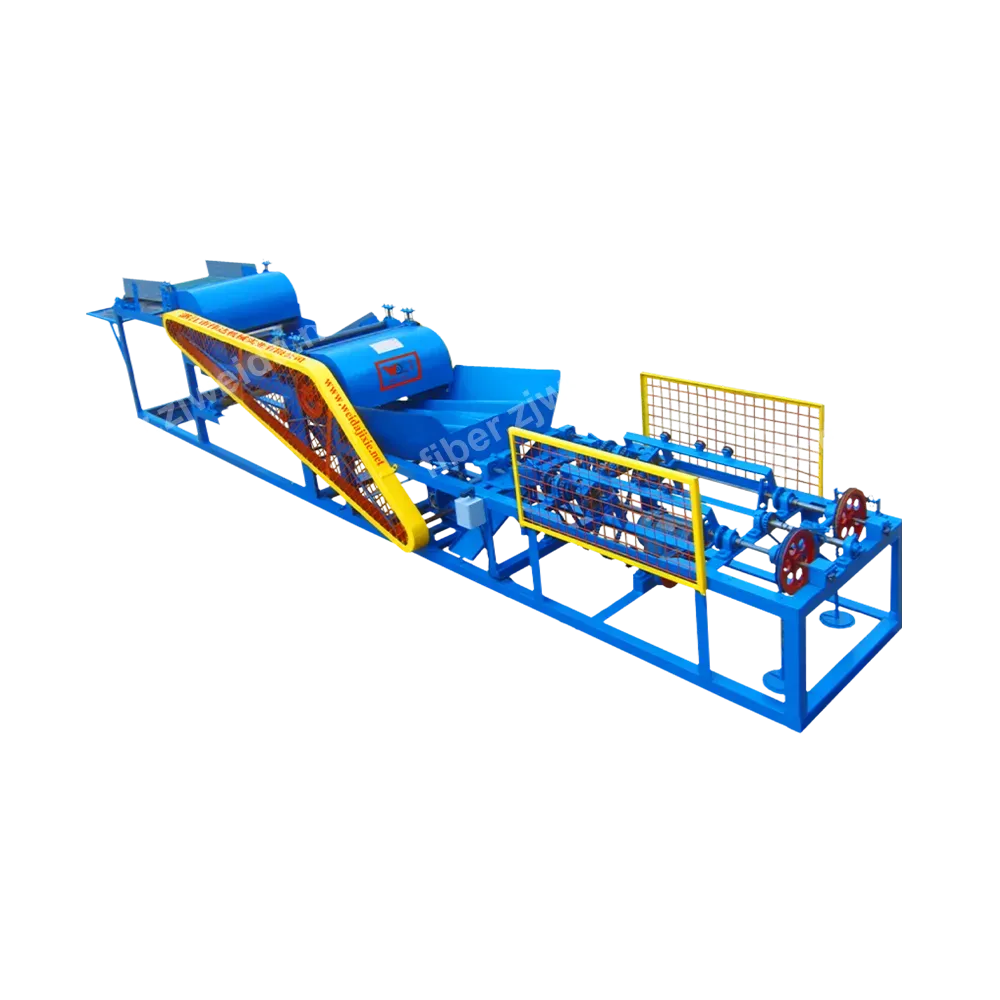

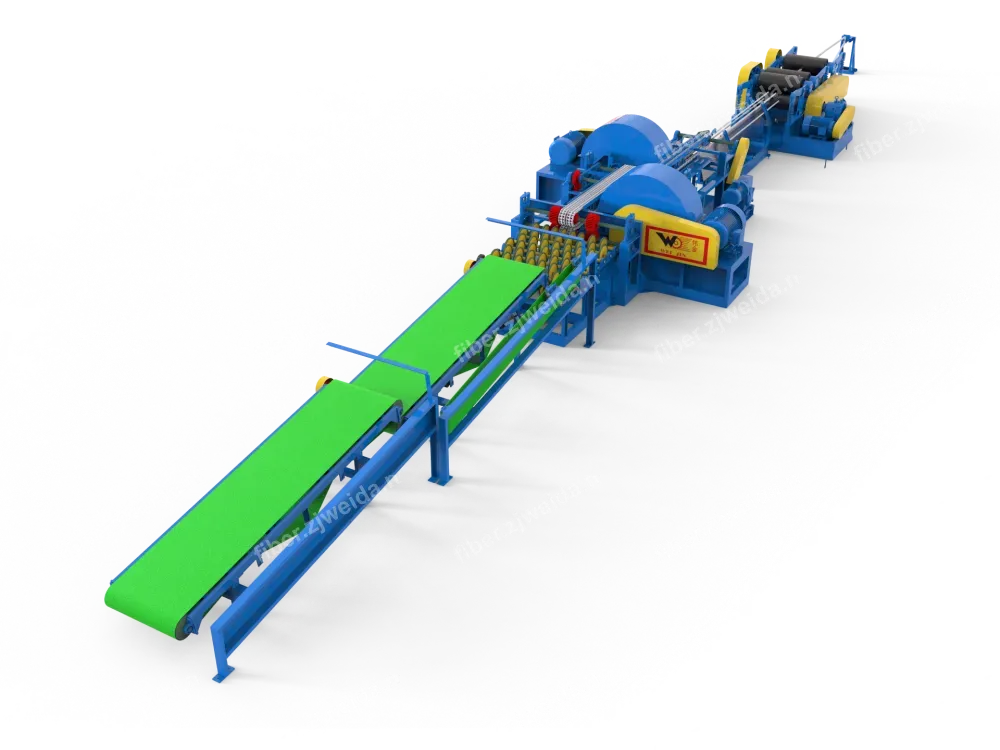

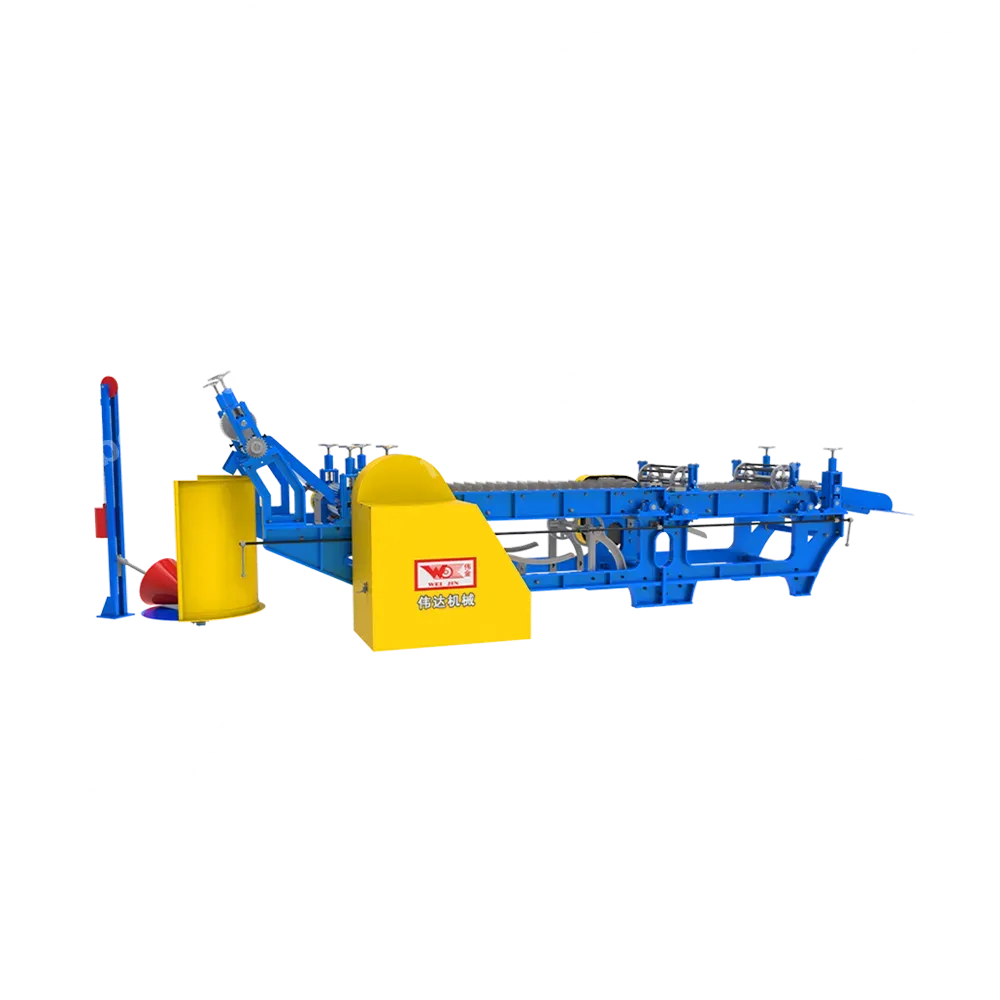

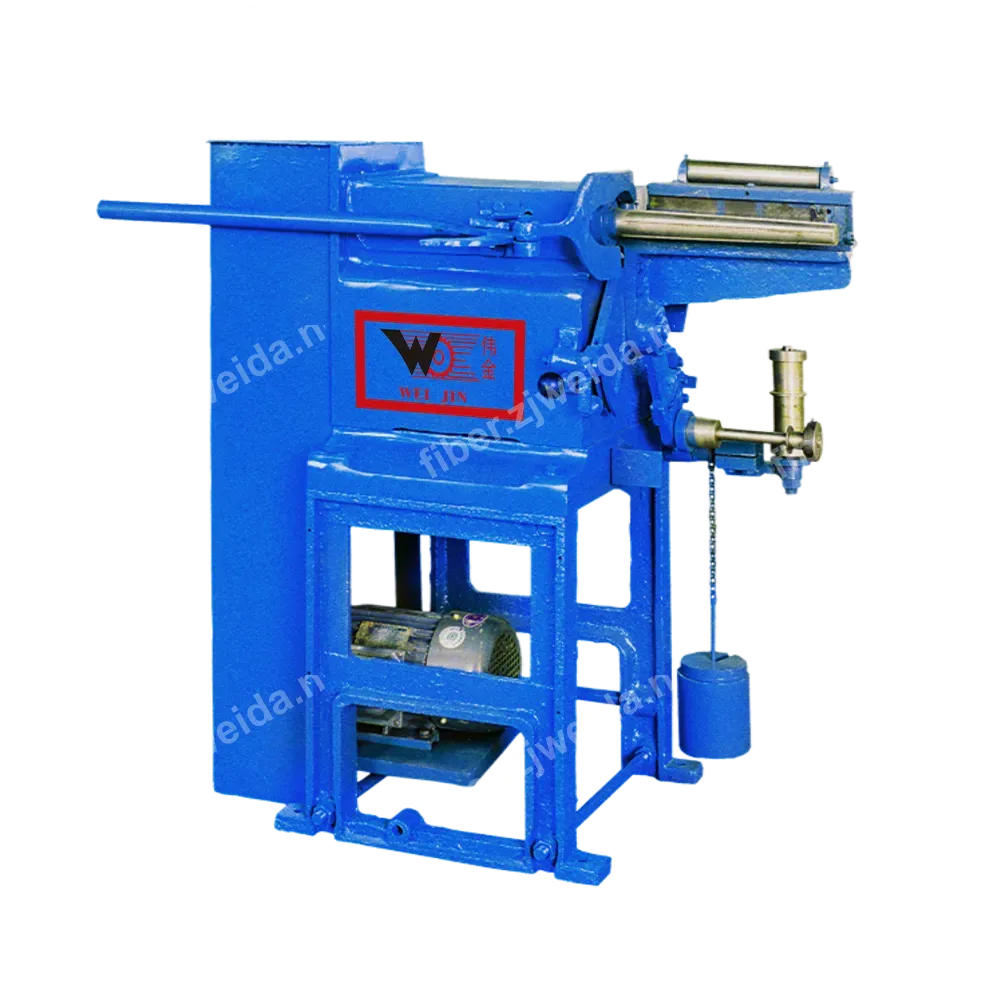

Full Industry Chain Equipment: From plant fiber extraction, cleaning, baling, to short fiber rope making, spinning, and residue treatment, providing complete production line equipment.

Wide Materials

Full Chain

One-Stop

Efficient & Eco

Core Advantages: Professional Quality

Combining market pain points with innovation needs, Weida Machinery has built a competitive core value system:

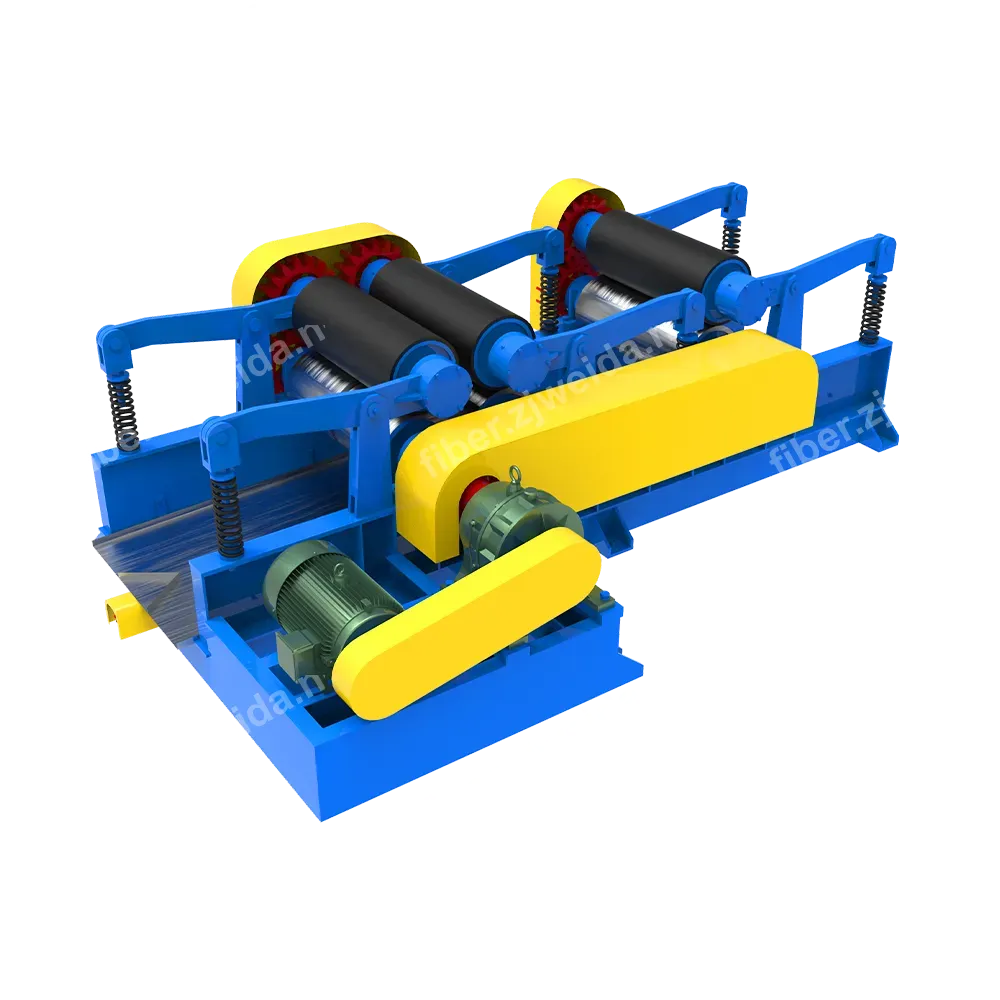

Multi-dimensional Matrix: Meeting production needs of different scales (Mobile/Economic/Automated).

Value Loop: Promoting green processing, turning waste into treasure (Residue/Short Fiber Reuse).

Solid Workmanship: Fearless of high heat and humidity, ensuring continuous production in tropical environments.

Multi-Matrix

Value Loop

Solid Build

Env. Adapted

Future R&D: Exploring Tomorrow

We do not stop at the present, but focus on future fiber application exploration:

Fiber Application Lab: Conducting Mulberry Branch fiber extraction experiments to expand fiber sources.

Process Upgrade: Promoting Forage and Plant Dewatering process upgrades, providing new ideas for agricultural deep processing.

Fiber Lab

Mulberry Ext.

Dewatering

Exploration

20+

Years

Experience

Innovating Plant Fiber

Processing Technology.

Weida Machinery Since 2004

Global Cases

Global Cases

Success Stories from

Around the World

1000-ton Sisal Fiber Extraction Production Line in Tanzania, 2025

- Location: Tanzania

- Year: 2025

This project builds a highly automated, high-capacity production line for sisal fiber extraction in Tanzania, with an an...

1000-ton Sisal Fiber Extraction Production Line in Tanzania, 2025

- Location: Tanzania

- Year: 2025

This project builds a highly automated, high-capacity production line for sisal fiber extraction in Tanzania, with an an...

Linha de Produção de Extração de Fibra de Sisal de 1000 toneladas na Tanzânia, 2025

- Location: Tanzânia

- Year: 2025

Este projeto constrói uma linha de produção altamente automatizada e de alta capacidade para extração de fibra de sisal...

Mstari wa Uzalishaji wa Uchimbaji wa Nyuzi za Katani wa Tani 1000 nchini Tanzania, 2025

- Location: Tanzania

- Year: 2025

Mradi huu unajenga mstari wa uzalishaji wa kiotomatiki sana na wenye uwezo mkubwa wa uchimbaji wa nyuzi za katani nchini...

FEATURED SOLUTIONS

FEATURED SOLUTIONS

Advanced Fiber Processing

Production Lines

WHY CHOOSE US

WHY CHOOSE US

Versatile Fiber Processing Capabilities

With modular designs and adaptive technology, our systems handle diverse natural fibers globally. We provide full-process coverage from raw material pretreatment to final extraction.

100 %

Full Process Coverage

Mainstream Economic Fibers

Expert processing of sisal, jute, and ramie. We configure wear-resistant components for coarse fibers and flexible modules for fine fibers to ensure optimal quality.

Agricultural By-Product Utilization

Transforming waste into value. Our integrated "wash-crush-extract" solutions turn pineapple leaves and banana stems into valuable fiber, widely used in the Philippines and Guatemala.

Specialty Fiber Customization

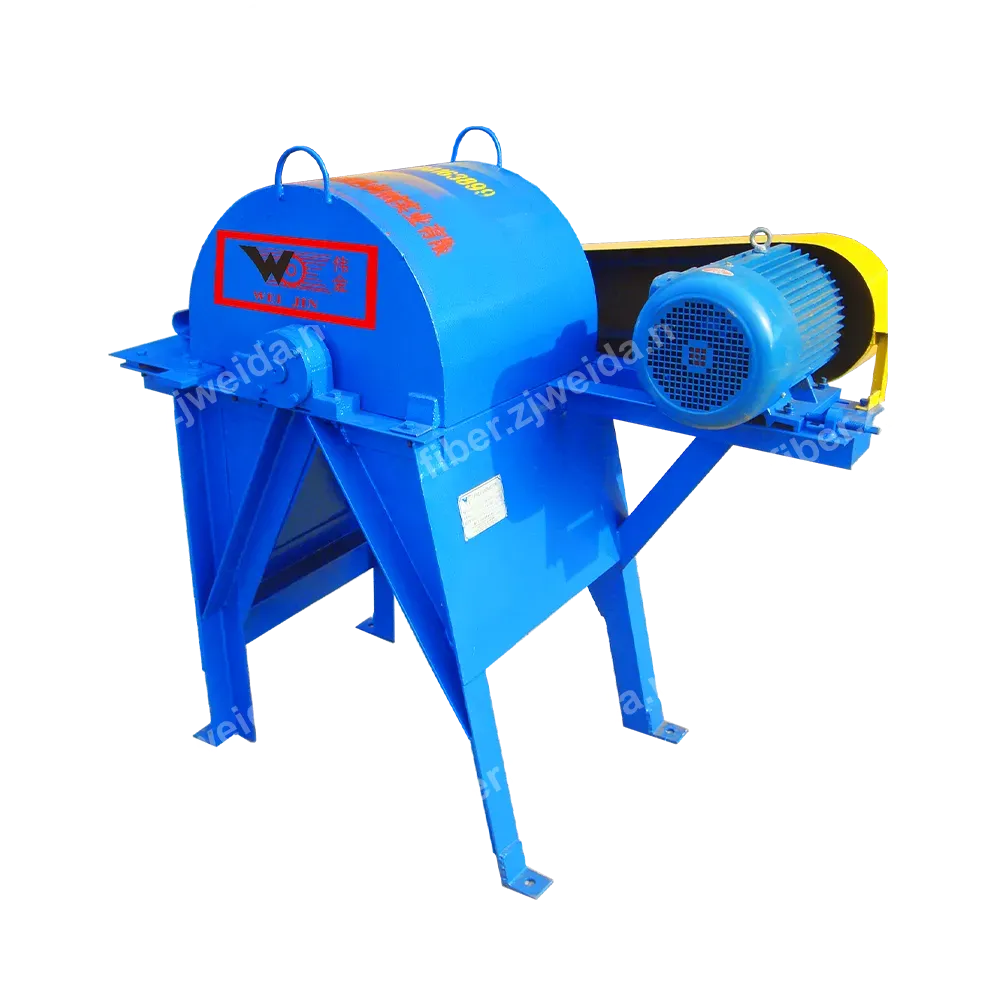

Tailored extraction for coconut coir and mountain palm. We use custom components to handle unique fiber structures, ensuring high purity and processing efficiency.

Core Technical Highlights

Advanced Engineering for Superior Fiber ProcessingHigh Capacity & Efficiency

Daily processing capacity up to 40 tons for core extraction units. Integrated automation workflow significantly improves production efficiency.

Energy Saving Design

Specialized drive systems reduce energy consumption by 18% compared to traditional equipment, delivering significant cost advantages.

Low Loss Extraction

Innovative flexible separation technology controls fiber breakage rate below 5%, retaining natural toughness and ensuring premium textile quality.

Global Adaptability

Tailored configurations for different regions: heat insulation protection for Africa, environmental compliance for Europe, and economic solutions for Southeast Asia.

24/7 Stable Operation

Manufactured with high-strength steel and wear-resistant components. Mean Time Between Failures (MTBF) exceeds 10,000 hours, supporting continuous production.

Green Resource Cycle

Features residue juice recovery and wastewater filtration functions, achieving an 85% recycling rate, minimizing waste and environmental costs.

OUR SERVICE PROCESS

OUR SERVICE PROCESS

Full-Process

Optimization Solutions

Transitioning from equipment supply to comprehensive solutions. We analyze, design, implement, and iterate to solve your unique production challenges.Advanced Fiber Processing Equipment

Explore our complete range of machinery. View All Products.

our latest cases

our latest cases

Explore Our Latest

Real Cases

- 26 December 2025

- Rope Making Solution

Horse Tail Hair Twisting Machine for Mattress Material

Read Details

- 15 December 2025

- Plant Fiber Processing

Economic Banana Stem Fiber Extraction Line in Guinea

Read Details

Plant Selection

Effective communication, respect, & shared objectives are for fostering

Soil Preparation

Effective communication, respect, & shared objectives are for fostering

Patience & Observe

Effective communication, respect, & shared objectives are for fostering

Book Appointment

Effective communication, respect, & shared objectives are for fostering