Tupigie

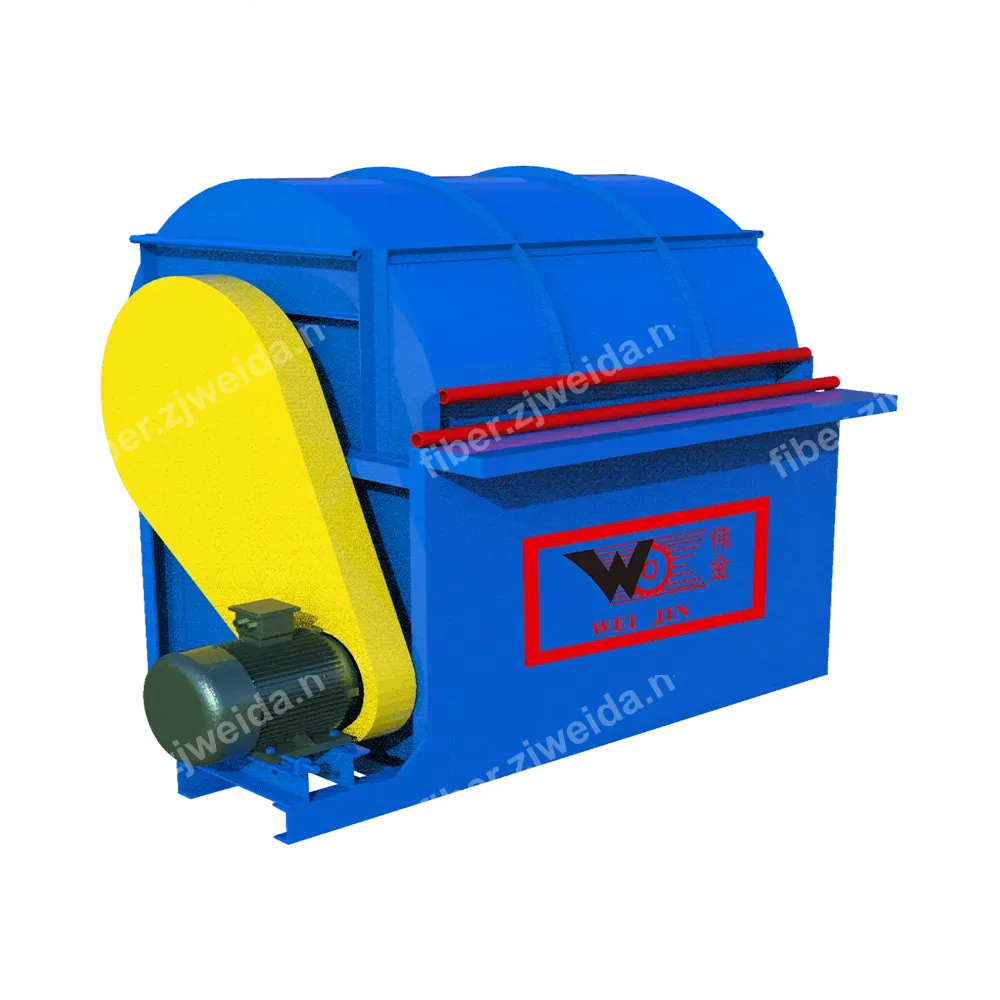

Mashine ya Kuchana Nyuzi

Uchanaji mzuri, kuondoa nyuzi fupi na uchafu, kuboresha kwa kiasi kikubwa unyofu wa nyuzi na daraja la soko.

Key Highlights:

- High Efficiency: High-speed rotating steel pin drums quickly straighten messy fibers.

- Grading: Effectively separates long fibers from short tow, increasing product value.

- Thorough Cleaning: Deep removal of fine pulp debris and dust remaining in the fiber.

- Safety Design: Ergonomic inlet design with safety guards to ensure operator safety.

Product Overview

The YSJ-1200 Circular Combing Machine is key equipment for plant fiber post-processing, mainly used for refining sun-dried raw hemp. Through high-speed rotating drums with pins, it combs fiber bundles, straightening tangled fibers and removing short fibers, messy fibers, and residual impurities. Fibers processed by this machine have brighter color, straighter strands, and extremely low impurity content, making them high-quality raw materials for high-end ropes and textiles.

Why Choose Us

Pin Combing Technology

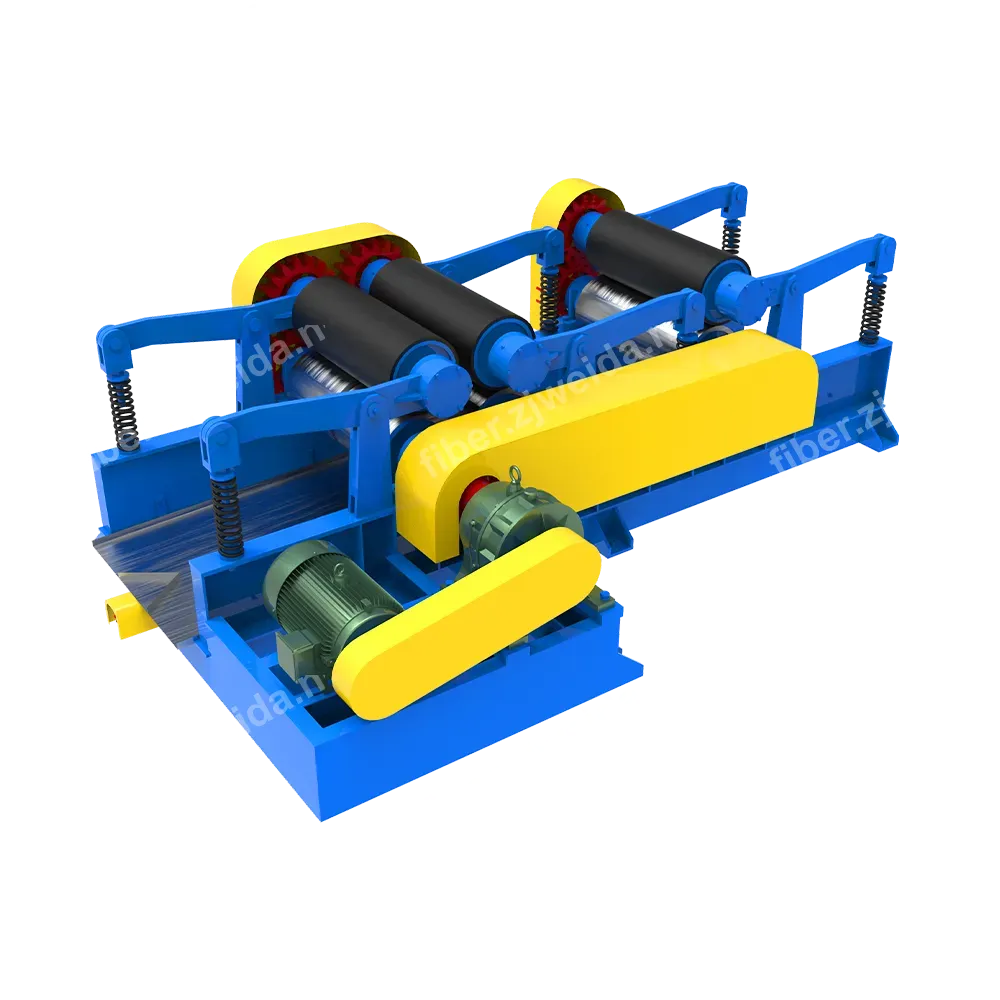

The core component is a large combing drum (1200mm diameter) with staggered special steel pins. At high speed (133r/min), pins penetrate the fiber layer, creating strong combing action to achieve both straightening and cleaning.

Low Damage Combing

Optimized pin density and speed matching ensure combing effectiveness while avoiding fiber breakage caused by excessive pulling, maximizing long fiber integrity.

Multi-category Compatibility

Adaptable to Sisal, Jute, Hemp, Ramie, Banana fiber, etc., without changing core parts.

Flexible Operation

Variable frequency control allows speed fine-tuning according to fiber type and moisture content for optimal results.

Process Flow

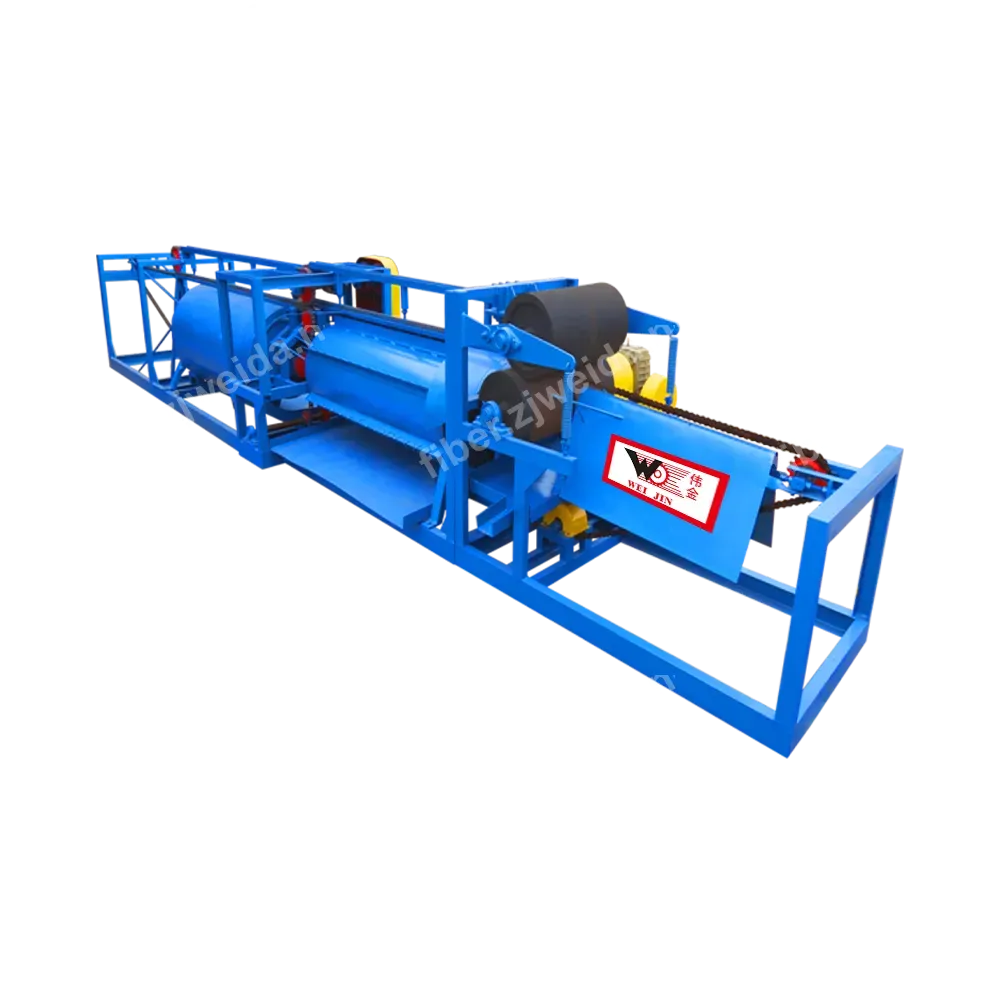

- 1.Preparation: Manually hold a bundle of dry fiber.

- 2.Head Combing: Feed fiber head into the inlet; the drum combs the head.

- 3.Turnaround: Withdraw fiber, turn it around, and hold the other end.

- 4.Tail Combing: Feed fiber tail into the inlet; the drum combs the tail.

- 5.Collection: Place combed long fibers aside; short tow falls into the bottom collection box.

Main Components

- Combing Drum

- Steel Pins

- Safety Guard

- Motor

Application Scenarios

Export Fiber Processing

Producing high-grade 'Combed Hemp'.

Rope/Spinning Prep

Providing straight raw materials for drawing frames.

Recommended Matching Equipment

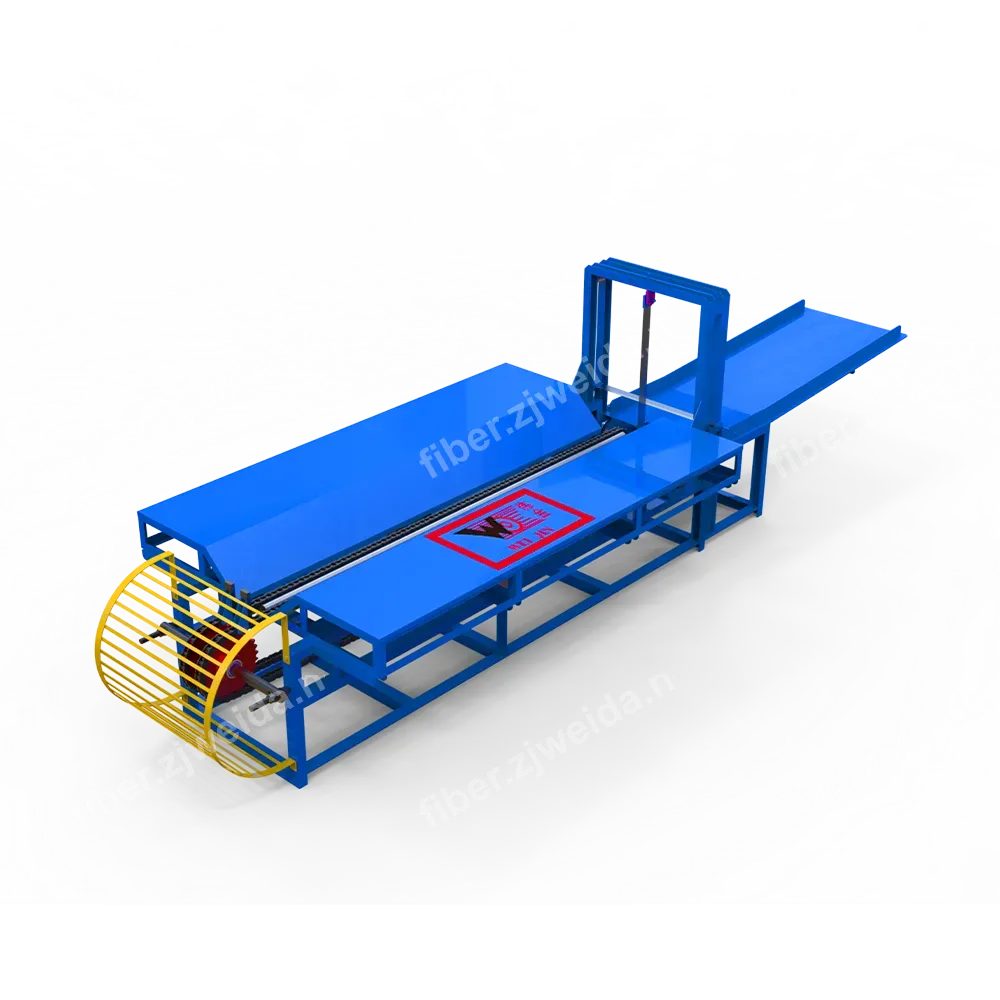

Fiber Baling Machine

Baling finished combed fiber.

Short Fiber Baler

Collecting and baling short tow from the bottom.

| Mfano | YSJ-1200 |

| Malighafi | Katani, Juta, Rami, Nyuzi za Ndizi, nk. |

| Kipenyo cha Ngoma | 1200 mm |

| Upana wa Ngoma | 495 mm |

| Kasi | 133 r/min (Inaweza kubadilishwa) |

| Nguvu | 4 kW |