Tupigie

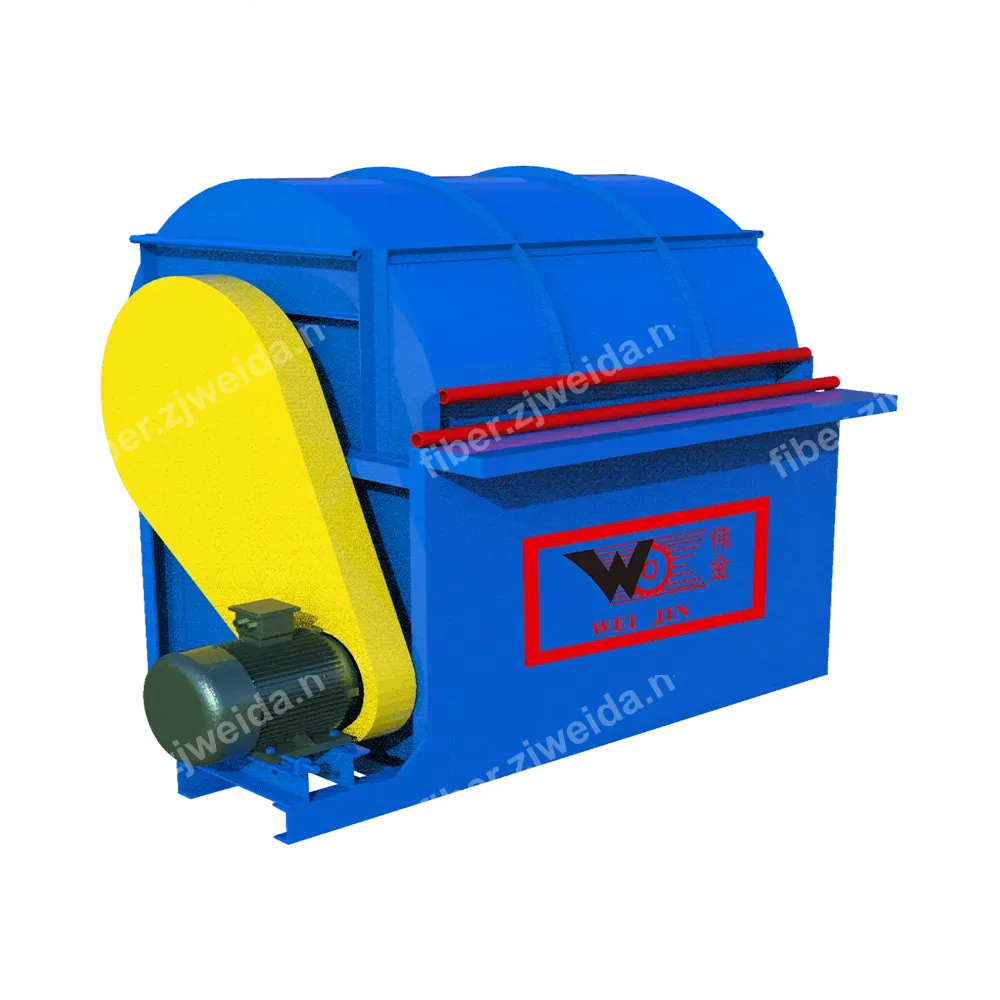

Mashine ya Kusafisha Nyuzi

Upigaji wa kimwili kwa ajili ya kuondoa uchafu, rafiki kwa nyuzi, huondoa kwa ufanisi polpa na vumbi, kuongeza thamani ya nyuzi.

Key Highlights:

- High Efficiency: Impurity removal rate ≥98%, thoroughly clearing residual pulp and impurities.

- Physical Process: Uses rotating beating method, no chemical additives, preserving natural fiber structure.

- Wide Compatibility: Compatible with Sisal, Pineapple, Banana, Hemp, and other plant fibers.

- Rich Models: Various specifications available to meet capacity needs from small workshops to large factories.

Product Overview

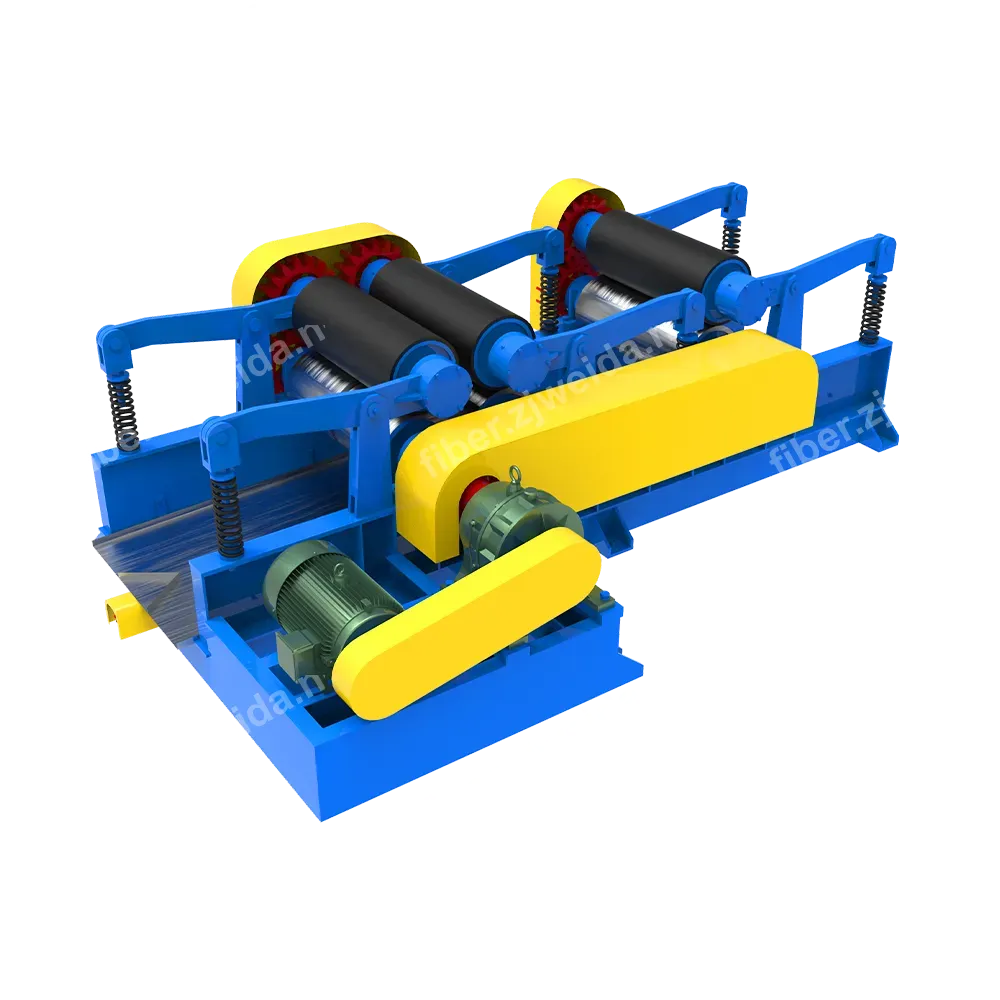

The CZ Series Fiber Cleaning Machine is specialized equipment developed by Weida Machinery for deep cleaning of dried plant fibers. After primary processing (decortication), fibers often retain small amounts of pulp, pectin debris, and dust. This machine uses high-speed rotating brushing rollers to separate these impurities from the fiber through mechanical beating and centrifugal force, making the fiber fluffier, cleaner, and smoother, meeting standards for textiles or high-end products.

Why Choose Us

Physical Beating, Protecting Fiber

Adopts 'physical rotating beating' technology. Flexible or rigid beating actions of the rollers cause impurities adhering to the fiber to fall off naturally. Compared to chemical degumming, this method preserves fiber physical strength and natural characteristics.

Multi-stage Cleaning

Can be configured with single or multiple cleaning rollers in series to ensure deep impurities are effectively removed, controlling impurity content to within 3%.

Simple Structure, Low Maintenance

Mainly consists of a frame, brushing rollers, and motor. The structure is streamlined with very low failure rates. Daily maintenance only requires clearing collected impurities at the bottom.

Process Flow

- 1.Drying: Ensure fibers are sun-dried or machine-dried.

- 2.Manual Feeding: Feed dry fibers manually or via conveyor into the inlet.

- 3.Beating & Cleaning: Fibers are repeatedly beaten and shaken by rollers.

- 4.Separation: Pulp and dust fall into the bottom collection area.

- 5.Collection: Clean fibers are discharged and collected manually.

Main Components

- Frame

- Brushing Rollers

- Motor

- Waste Collection Tray

Application Scenarios

Fiber Processing Post-treatment

Improve fiber quality and selling price.

Export Processing

Meet strict international standards for low impurity content.

Textile Prep

Provide clean raw material for spinning and rope making.

Recommended Matching Equipment

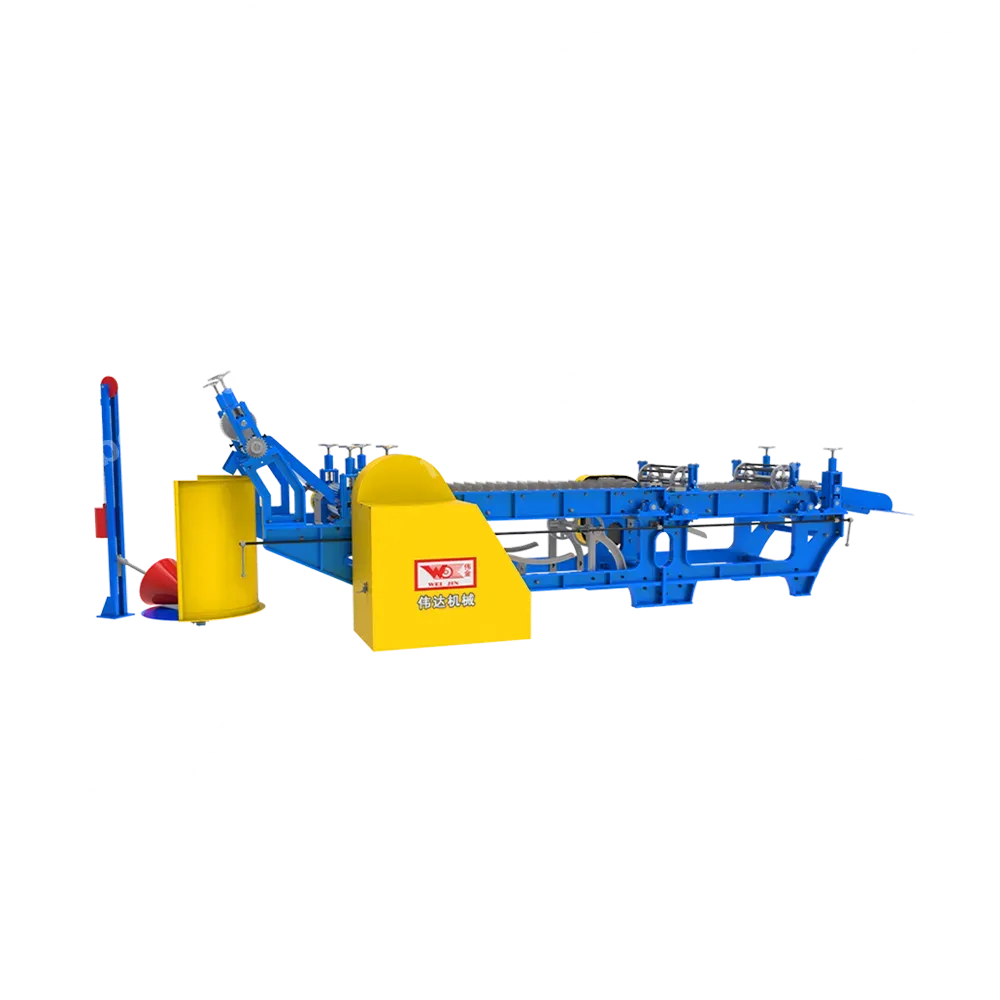

Fiber Baling Machine (XDB Series)

Fluffy cleaned fibers need immediate baling.

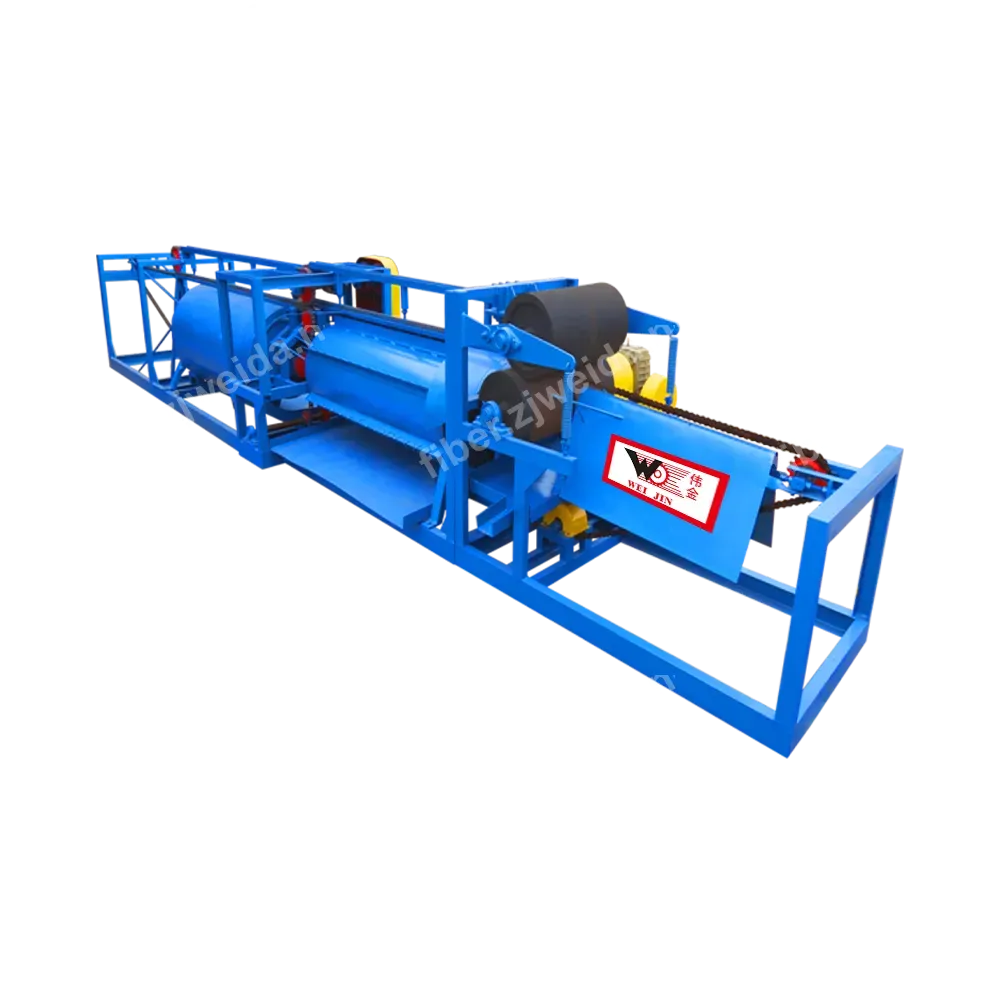

Fiber Extraction Machine (SGMX/ZGM Series)

Upstream extraction equipment.

| Mfano | CZ-1000*500 / CZ-1000*1000 / CZ-1000*2000 |

| Malighafi | Nyuzi Mbalimbali za Mimea Kavu |

| Kiwango cha Kusafisha | ≥98% |

| Nguvu | 4 kW - 5.5 kW |