Tupigie

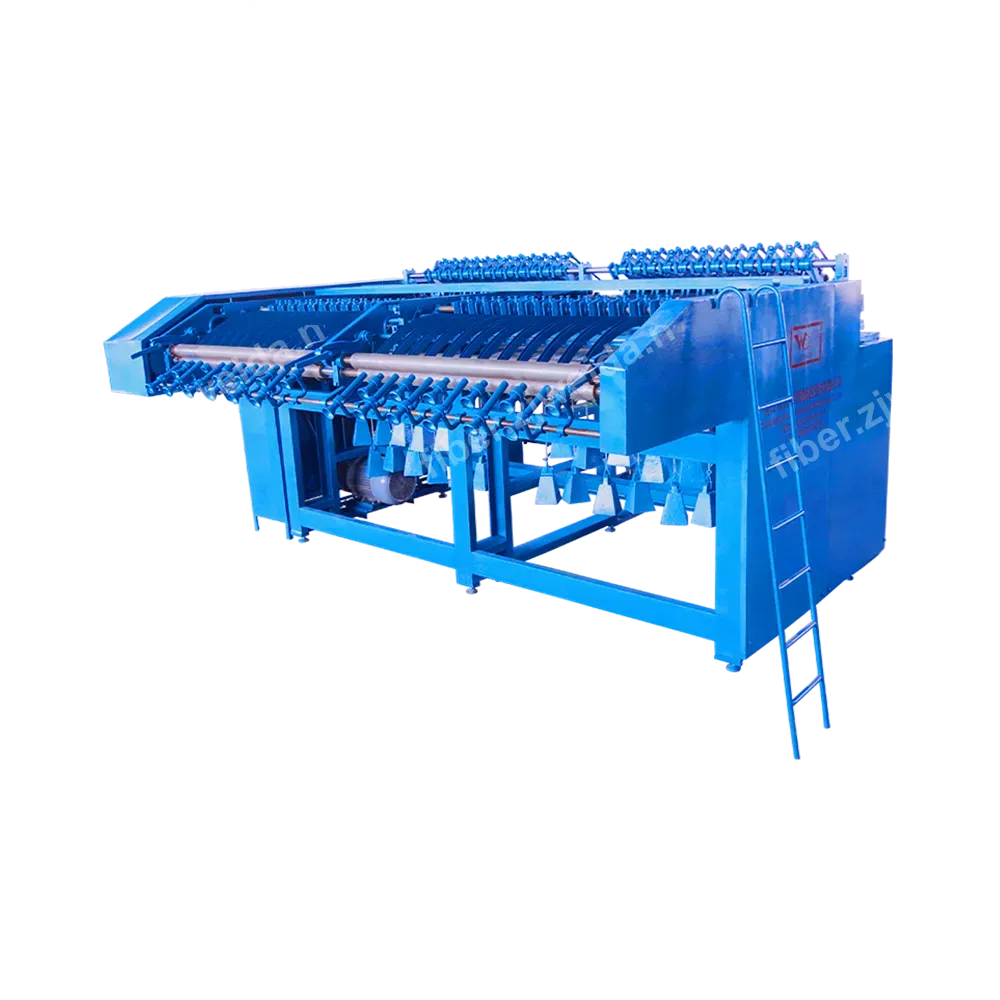

Mashine ya Kuchora (Drawing Machine)

Kuunganisha na kuvuta kwa usahihi, kuondoa kutokuwa na usawa wa utepe, kuweka msingi wa uzi wa ubora wa juu.

Key Highlights:

- Multi-pass Doubling: Combines multiple slivers into one, significantly reducing weight unevenness.

- Precision Drafting: Rubber pressure rollers ensure high fiber straightness and parallelism.

- Auto Cleaning: Equipped with cleaning devices to remove dust and defects from rollers in real-time.

- Multi-output: The 6-pass drawing frame can split coarse sliver into 6 fine slivers, ensuring high efficiency.

Product Overview

The BJ Series Drawing Frame is a key equipment in the sisal spinning process, located after the combing machine and before the spinning machine. Its core functions are 'Doubling' and 'Drafting'. Doubling combines multiple slivers to improve uniformity through error compensation; Drafting attenuates the sliver, further straightening fibers. After processing through 2nd, 4th, or 6th drawing frames, slivers become uniform and compact, ready for direct spinning.

Why Choose Us

Integrated Process

Automated from sliver feeding to collection. The guiding mechanism ensures smooth feeding, drafting mechanism attenuates, cleaning device removes impurities, and finally, the coiler fills the can.

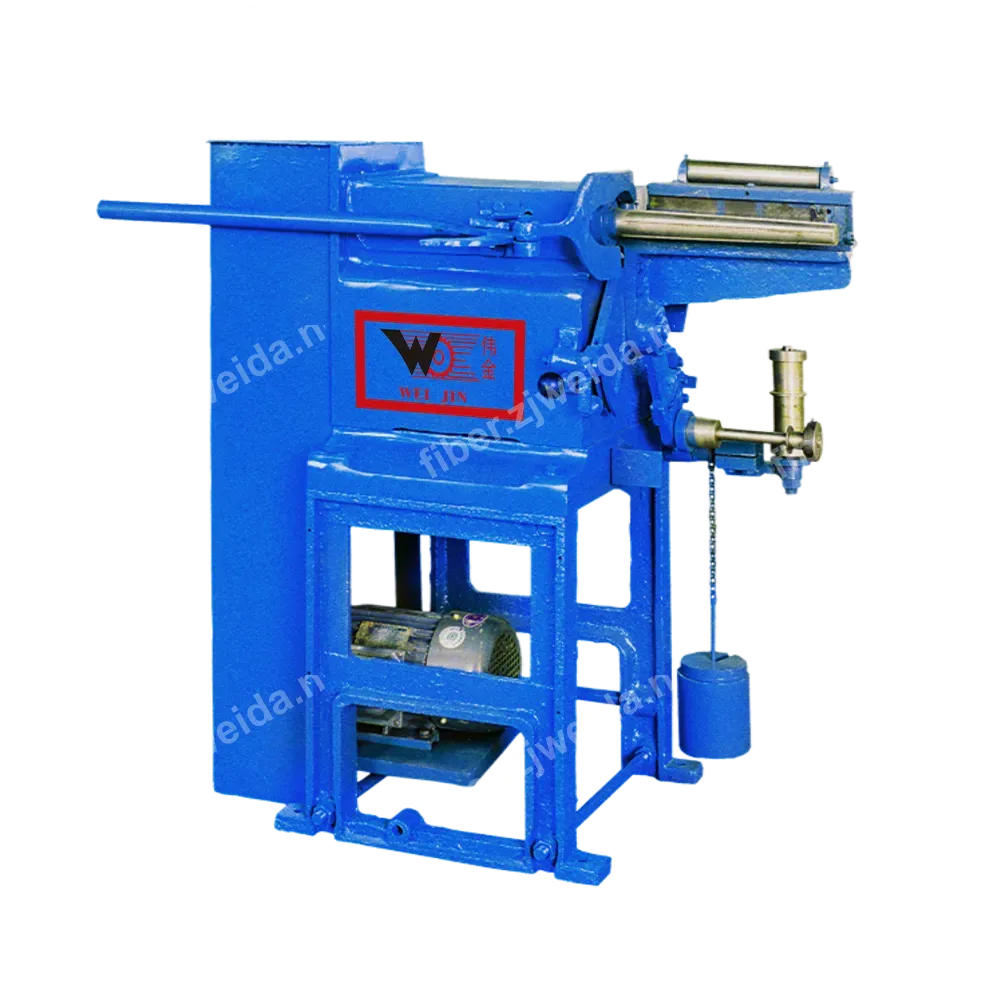

Rubber Pressure Rollers

Drafting section uses rubber rollers with excellent grip, protecting fibers while ensuring accurate drafting ratios.

Defect Reduction

Unique cleaning devices simultaneously remove short fibers and dust adhering to rollers, preventing them from entering the sliver and forming defects.

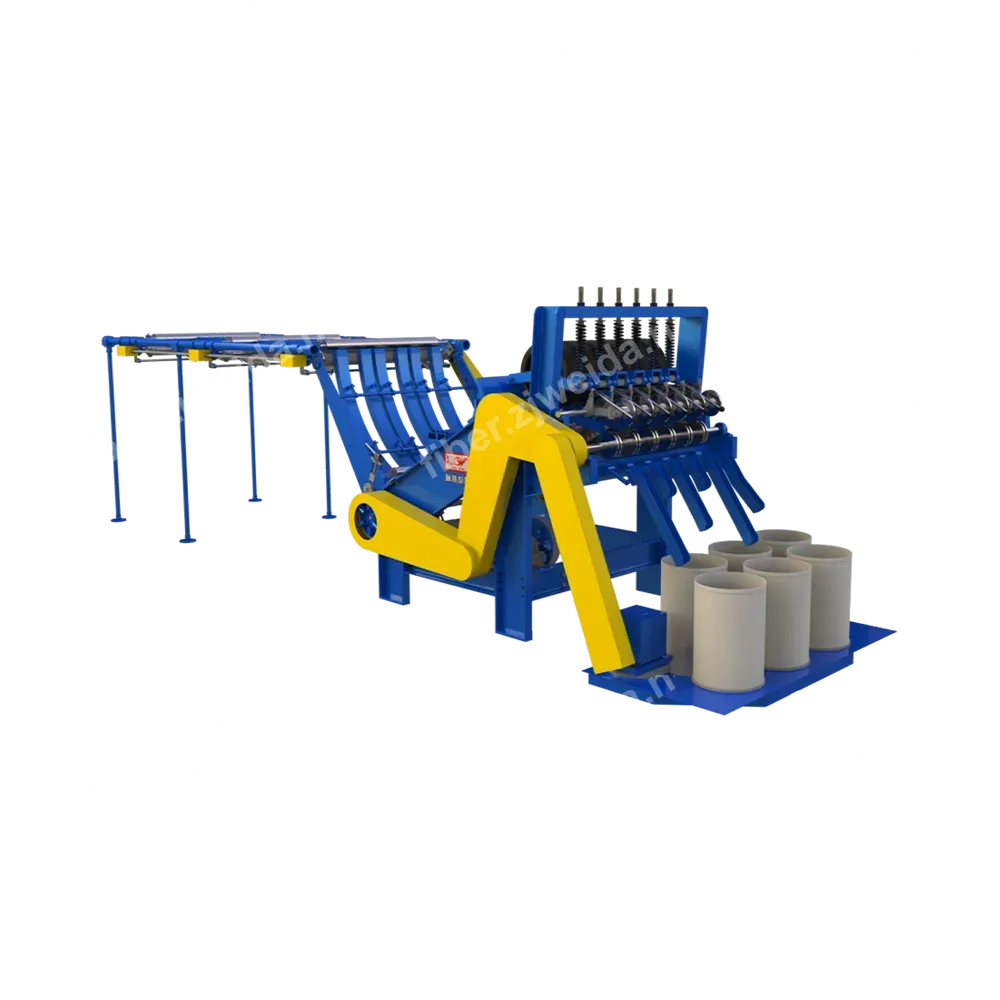

Stepwise Refinement

Usually configured with 2nd Drawing (BJ-9.5) and 6th Drawing (BJ-6). Coarse slivers are doubled and drafted, then further split, finally producing 14-24g/m fine slivers suitable for spinning.

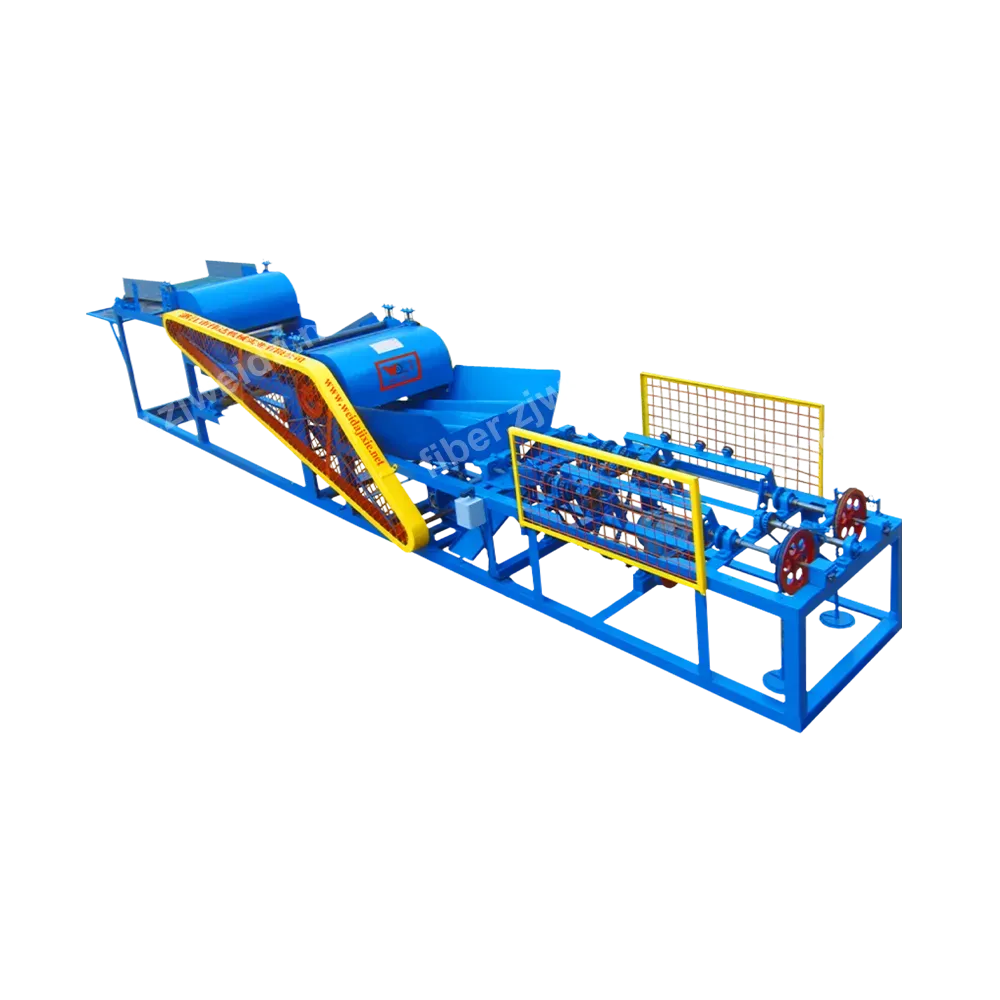

Process Flow

- 1.Feeding: Place hemp balls from the combing machine into feeding cans.

- 2.Doubling: Multiple slivers are fed simultaneously.

- 3.Drafting: Slivers are elongated and thinned through drafting rollers.

- 4.Splitting (6th): Coarse sliver is split into 6 fine strands.

- 5.Coiling: Fine slivers fall into rotating cans in a spiral pattern.

Main Components

- Guide Rollers

- Drafting Assembly

- Rubber Pressure Rollers

- Coiler

- Sliver Can

Application Scenarios

Fine Spinning

Essential for producing high-count sisal yarns.

Rope Making Prep

Providing uniform strands for rope machines.

Recommended Matching Equipment

Sisal Combing Machine

Upstream equipment.

Spinning Machine

Downstream equipment.

| Mfano | BJ-9.5 (Ya 2) / BJ-6 (Ya 6) |

| Uainishaji wa Pato | 14 - 60 g/m |

| Kiwango cha Uzalishaji | 125 - 470 kg/h |

| Nguvu | 4 kW - 5.5 kW |

| Matokeo | Njia 1 / Njia 6 |