Call Us

Yarn Winding Machine

Precision layering, tubeless forming, creating international standard high-quality yarn spools.

Key Highlights:

- Cross Winding: Cross winding pattern ensures stable spool structure that won't unravel when thrown.

- Tubeless Forming: Finished product needs no tube support, reducing consumable costs and easy to use.

- Standard Spec: Winding diameter 250mm (approx 10 inches), meeting international standards.

- Cast Iron Cam: Core traverse cam made of cast iron, wear-resistant, durable, long life.

Product Overview

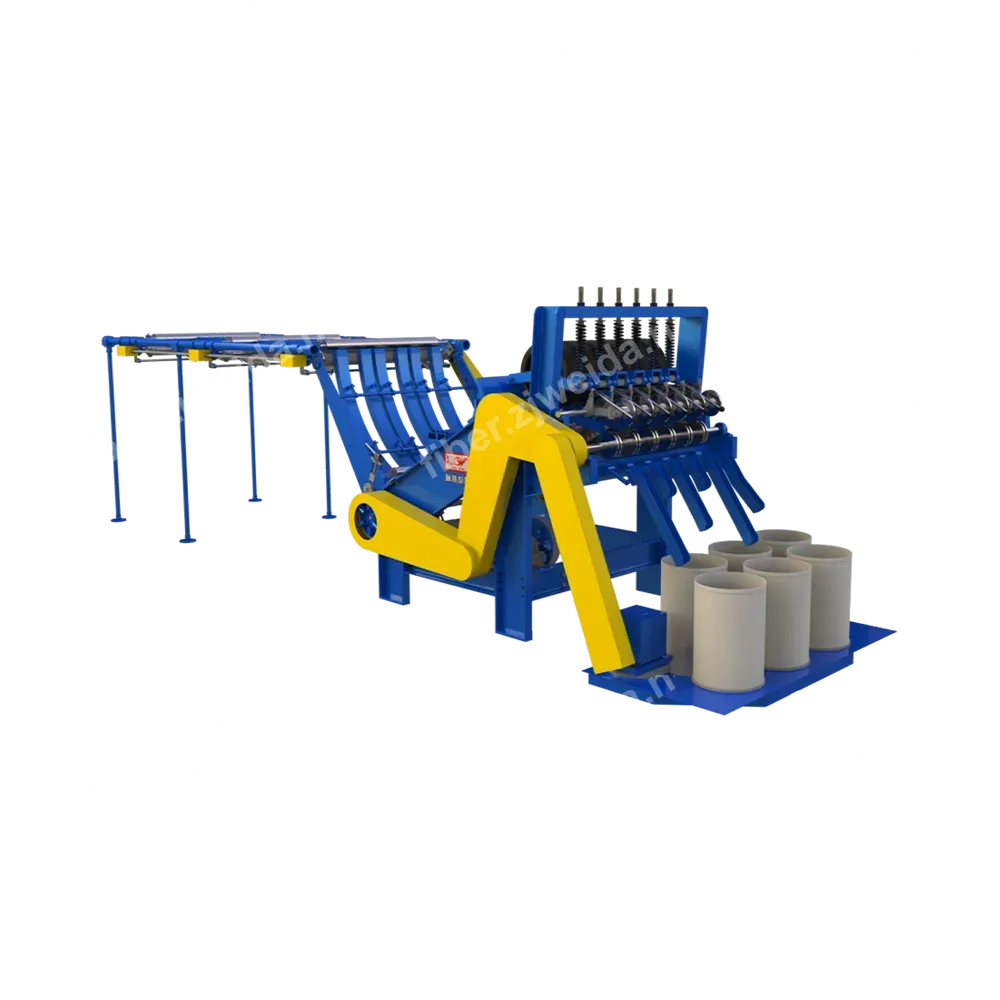

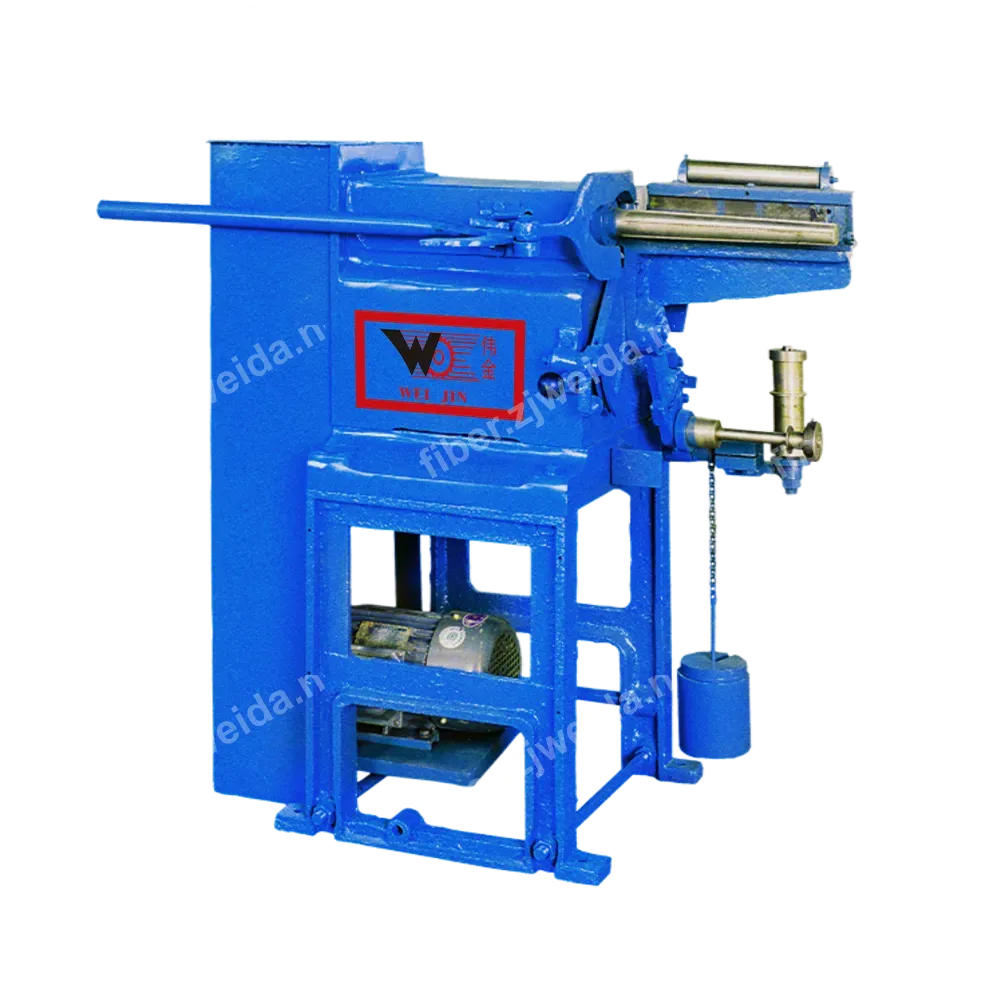

DL-250A Yarn Winding Machine (Spool Winder) is mainly used to rewind yarn cakes from spinning machines. Spinning cakes are often loose and irregular, unsuitable for transport or direct sale. This machine uses a precision cam traverse mechanism to wind yarn tightly and evenly into cylindrical spools with fixed diameter and beautiful appearance. These spools are tubeless, used from the center, the most popular packaging form for sisal yarn.

Why Choose Us

Tubeless Stable Winding

Using 'Herringbone' cross winding principle, yarn layers interlock. Even without a center tube, the finished spool maintains a strong geometric shape and won't collapse during long-distance transport.

High Efficiency

Simple structure, fast threading. Equipped with length counting or full-stop functions (optional), operators only handle loading/unloading, one person can manage multiple machines.

Cast Iron Cam, Smooth Run

The traverse cam is the heart of the winder. Weida Machinery insists on wear-resistant cast iron cams, which bear higher loads and run smoother than plastic ones, lasting much longer.

Beautiful Finish

Wound spools have smooth surfaces and clear patterns, greatly enhancing product appearance and market competitiveness.

Process Flow

- 1.Loading: Place spinning cake on supply rack.

- 2.Threading: Pass yarn head through tensioner and traverse fork, fix on expanding mandrel.

- 3.Winding: Start machine, mandrel rotates, traverse fork moves back and forth.

- 4.Forming: Yarn gradually winds into 250mm diameter cylinder.

- 5.Unloading: Contract mandrel, remove finished spool, pack.

Main Components

- Traverse Box

- Cast Iron Cam

- Expanding Mandrel

- Tensioner

- Motor

Application Scenarios

Hemp Mill Finishing

Essential step before yarn shipment.

Rope Factory

Rewinding large cakes into small spools for rope machines.

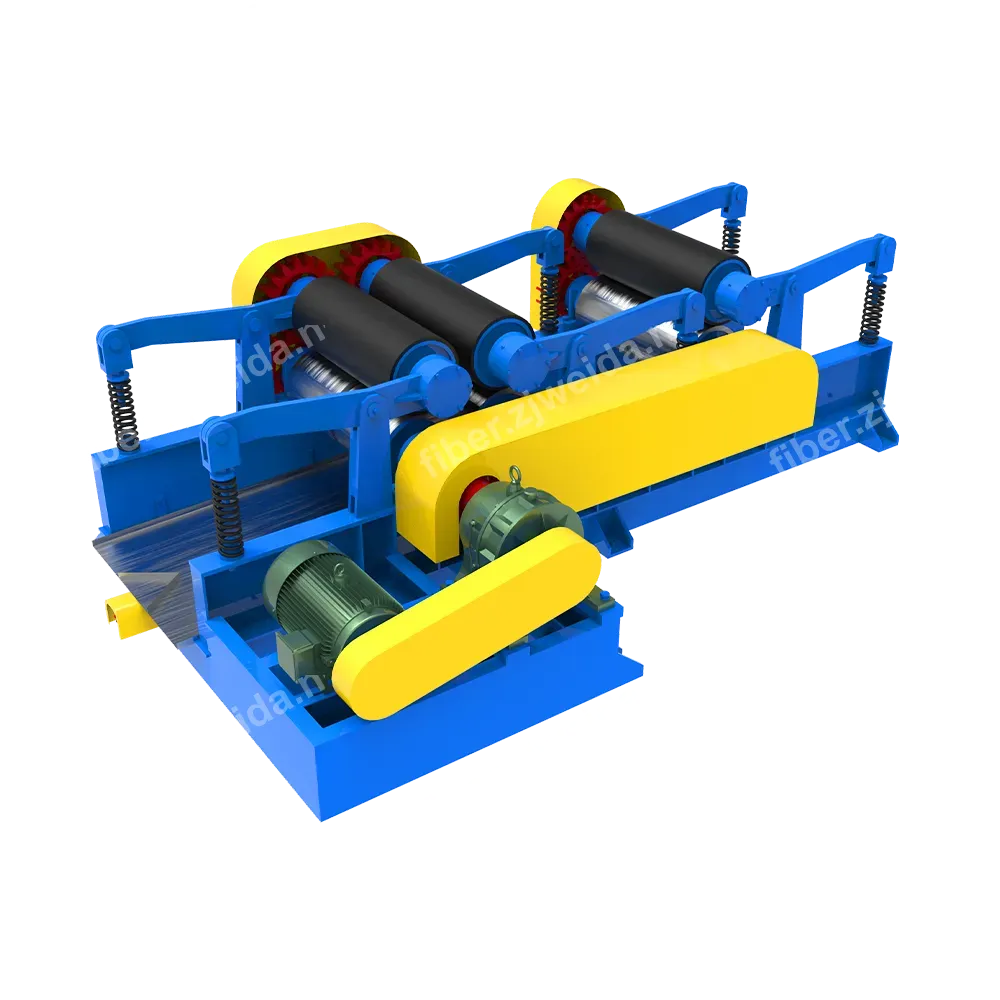

Recommended Matching Equipment

Spinning Machine

Upstream process.

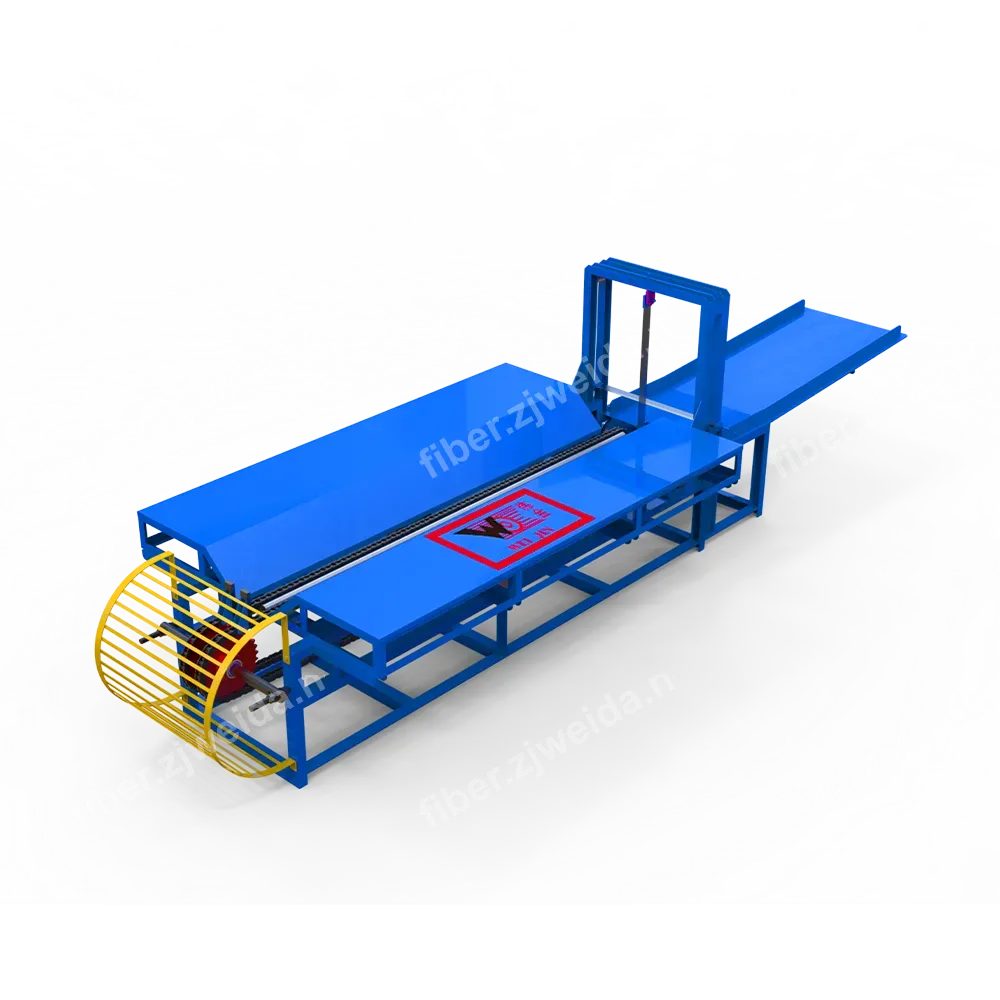

Baling Machine

Packing multiple spools into boxes.

| Model | DL-250A |

| Diameter | 250 mm (Approx 10 inch) |

| Winding Spec | 150-600 m/kg |

| Winding Type | Cross Winding |

| Power | 1.5 kW |

| Dimensions | 1025*1020*690 mm |

| Operation | Single/Multi Spindle Combination |