Call Us

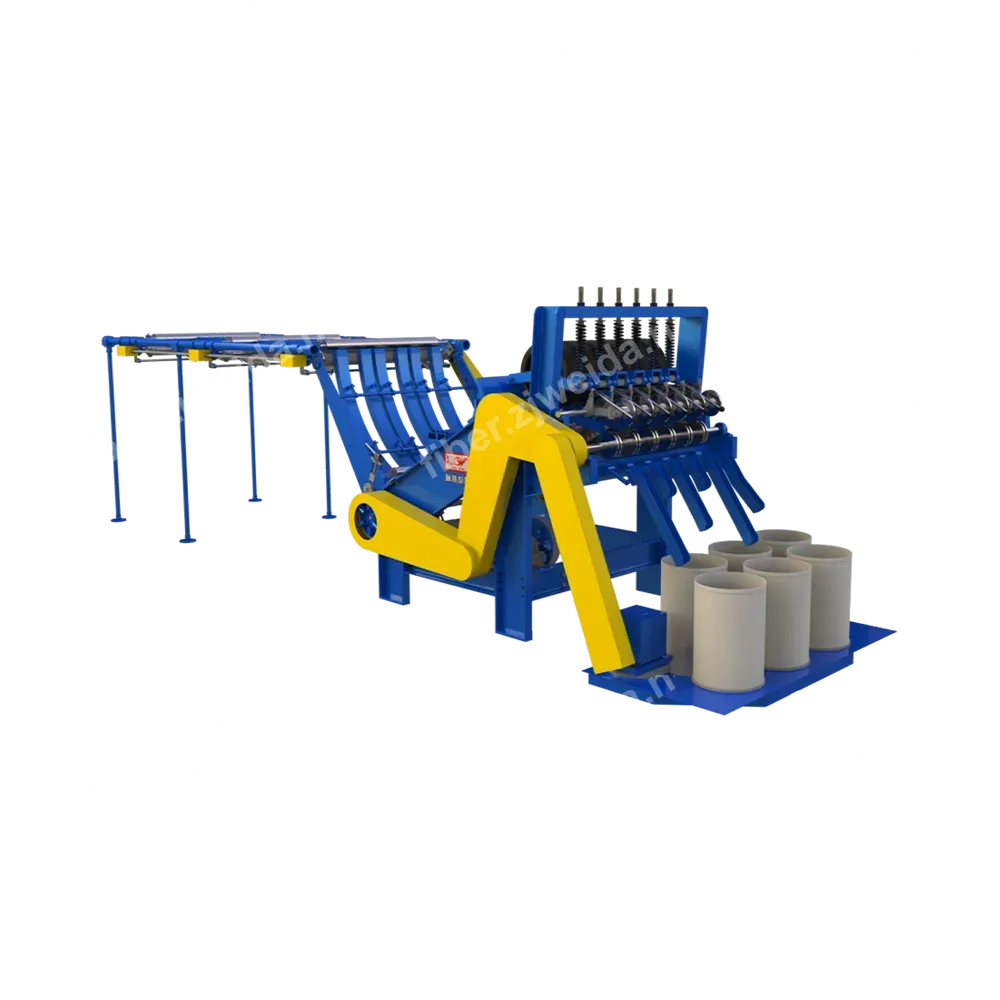

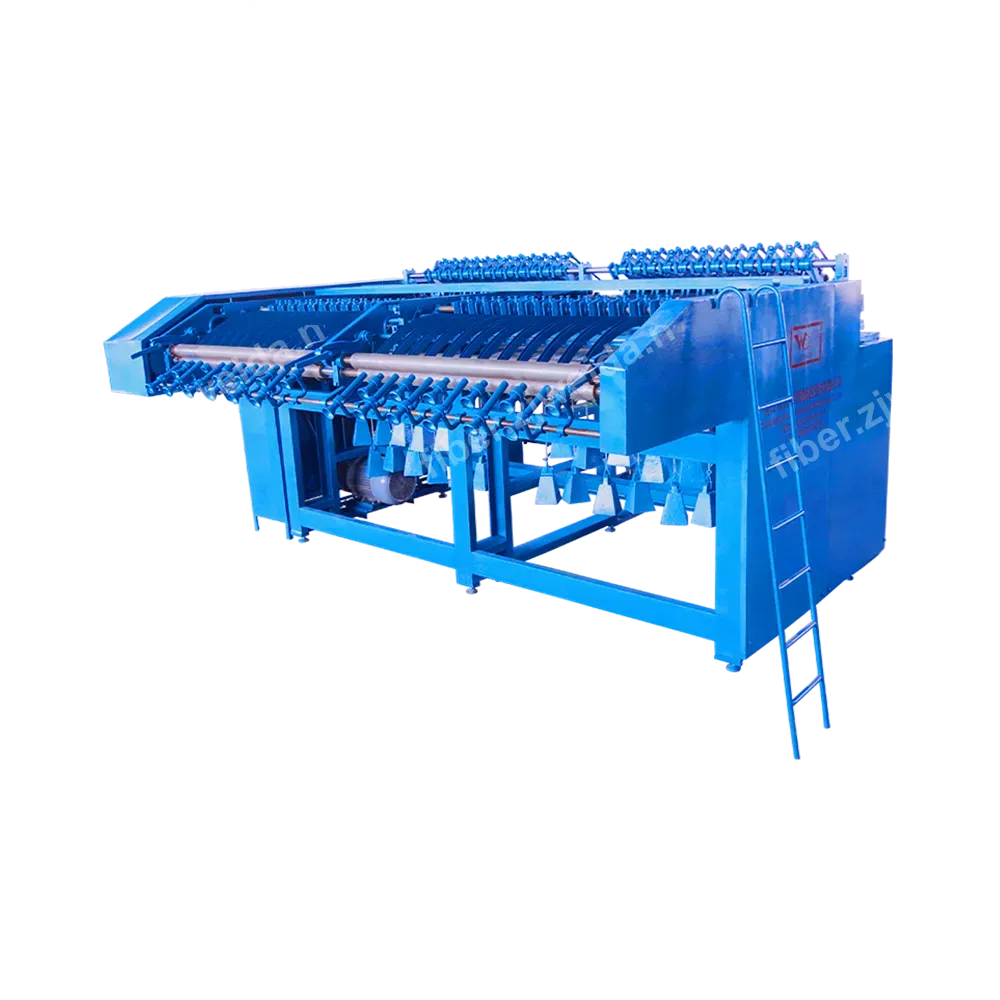

Spinning Machine

High-speed twisting, fine yarn formation, the ultimate process transforming plant fibers into high-strength yarns.

Key Highlights:

- Integrated Yarn Formation: Drafting, combing, cleaning, and twisting in one step, directly producing finished yarn.

- High Speed & Efficiency: 24 spindles synchronous operation, shift output up to 400kg.

- Inverter Control: Speed flexible adjustment according to yarn count requirements, strong process adaptability.

- Low Breakage Rate: Fork-cover flyer design, smooth operation, low breakage rate.

Product Overview

FW-24 Spinning Machine (Spinning Frame) is the terminal host of sisal and hard fiber spinning lines. It receives prepared slivers from drawing frames, performs final fine combing through a unique double-screw gill box to remove tiny impurities and parallelize fibers, then twists them via high-speed flyers to impart strength, finally winding into yarn cakes. Widely used for sisal yarn, banana yarn, and other long fiber yarns.

Why Choose Us

Refined Combing Structure

Equipped with Double-Screw Gill Box. Compared to ordinary roller drafting, pin bars better control fiber movement, ensuring even yarn evenness and less hairiness.

Fork-Cover Flyer

Uses fork-cover flyer structure with low air resistance and smooth rotation. This design facilitates threading and effectively reduces yarn breakage at high speeds, improving efficiency.

Excellent Yarn Quality

Produced yarns have tight structure, uniform twist, and high tensile strength. Ideal for high-end polishing wheels, wire rope cores, and crafts.

Easy Operation & Maintenance

Equipped with worm gear lifting device for smooth forming action. Core transmission box is well sealed with low failure rate.

Process Flow

- 1.Feeding: Introduce fine slivers from cans into machine.

- 2.Combing & Drafting: Fibers combed straight and drafted thinner through gill box.

- 3.Twisting: Sliver exits front roller, enters high-speed flyer to gain twist.

- 4.Winding: Twisted yarn wound onto bobbin.

- 5.Forming: Lifting mechanism moves rail up and down to form cylindrical yarn cake.

Main Components

- Gill Box

- Flyer

- Spindle

- Lifting Mechanism

- Inverter Motor

Application Scenarios

Rope Company

Producing fine yarns as rope strands.

Polishing Material Factory

Producing yarns for sisal polishing wheels.

Craft Factory

Producing hemp twine for crafts.

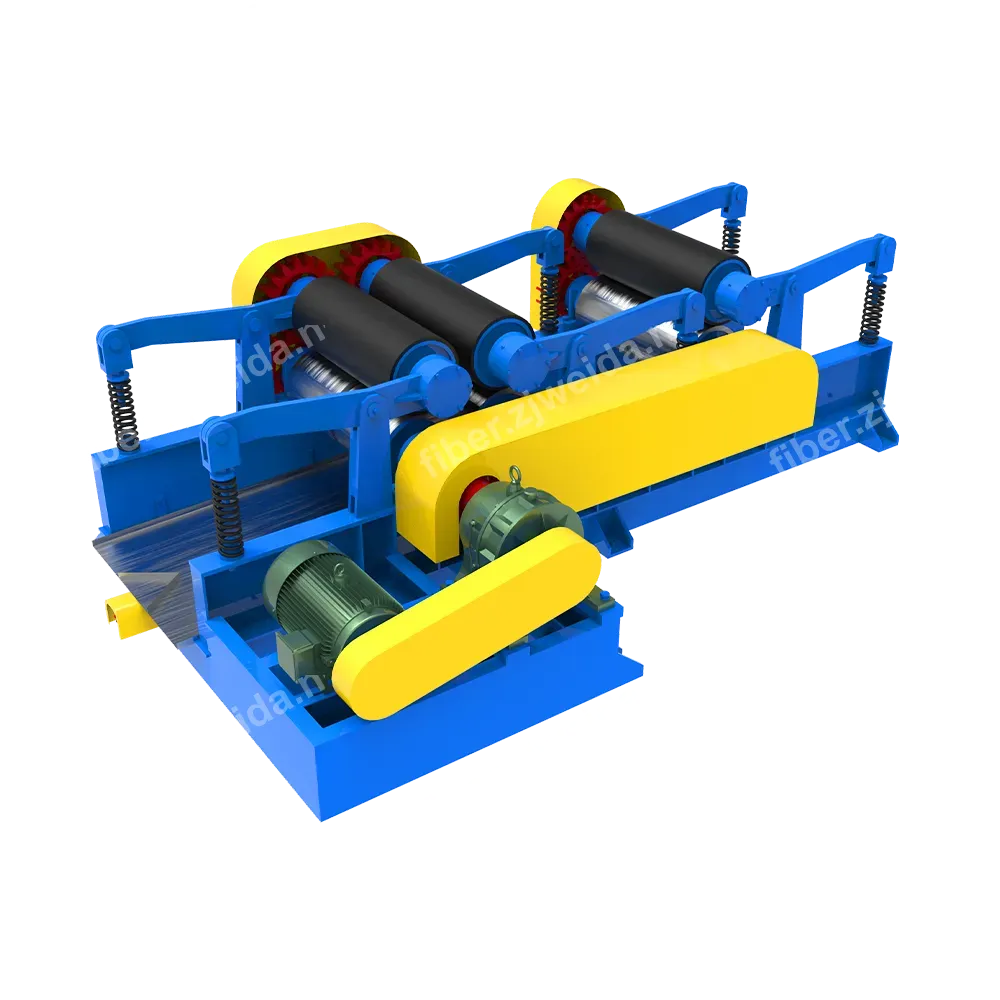

Recommended Matching Equipment

Drawing Frame

Upstream equipment.

Winding Machine

Downstream equipment, for rewinding yarn cakes.

| Model | FW-24 |

| Spindles | 24 Spindles |

| Materials | Sisal, Banana Fiber, Jute, etc. |

| Yarn Count | 0.3 - 0.6 g/m (High Count) |

| Output | 200-400 kg/Shift (8h) |

| Speed | 1800 rpm (Adjustable) |

| Power | 11 kW |

| Dimensions | 3.2*2.5*1.7 m |

| Weight | 4 Ton |