Call Us

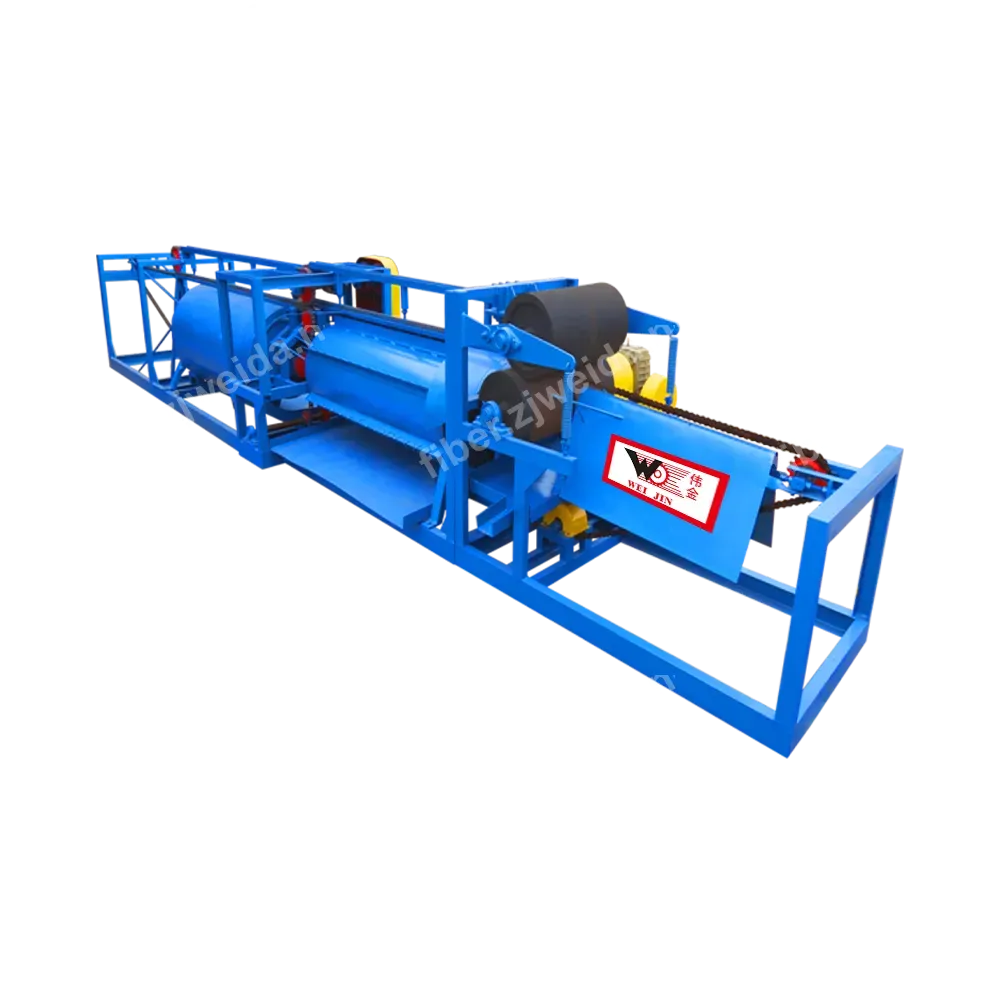

Sisal Residue Juice Extractor

Key to turning waste into treasure, efficiently separating moisture from waste, recovering high-value plant juice, enabling green circular production.

Key Highlights:

- Efficient Dewatering: Juice extraction rate ≥80%, significantly reducing waste volume and weight.

- Resource Recovery: Recovered sisal/banana juice is rich in nutrients, excellent raw material for liquid fertilizer.

- Screw Extrusion: Pure physical pressing, stainless steel cone head, wear and corrosion resistant.

- Flexible Adjustment: Adjustable outlet size to precisely control residue dryness.

Product Overview

JZ Series Sisal Residue Juice Extractor is eco-friendly equipment tailored by Weida Machinery for plant fiber processing plants. Fiber extraction produces large amounts of juicy leaf pulp waste. Direct discharge pollutes and wastes resources. This machine uses screw propulsion extrusion to squeeze out water and active ingredients (like sisal saponin, banana tannin, potassium) from waste. The separated dry residue is easy to compost or burn, and juice can be collected.

Why Choose Us

Excellent Material, Durable

Contact parts and cone head made of 304 stainless steel, highly resistant to oxidation and corrosion, adapting to acidic plant juices. Thick steel body structure is stable.

Adjustable Dryness

Unique outlet adjustment structure allows operators to flexibly adjust residue dryness according to downstream needs (composting, burning, or feed).

High Output, Low Consumption

Scientific design, reasonable power (15-18.5kW), large capacity (up to 10 tons/hour), low unit energy consumption, high cost-performance.

Automated Connection

Can be placed directly under decorticator waste outlet, automatic feeding via conveyor, no manual handling needed, fully automated waste treatment.

Process Flow

- 1.Waste Conveying: Wet waste from extractor enters juice extractor via conveyor.

- 2.Screw Propulsion: Internal screw blades push waste forward.

- 3.Squeeze Separation: As space narrows and pressure rises, juice flows through screen, solids are squeezed.

- 4.Juice Collection: Juice flows into collection pool via trough.

- 5.Dry Residue Discharge: Dewatered residue discharged from cone head.

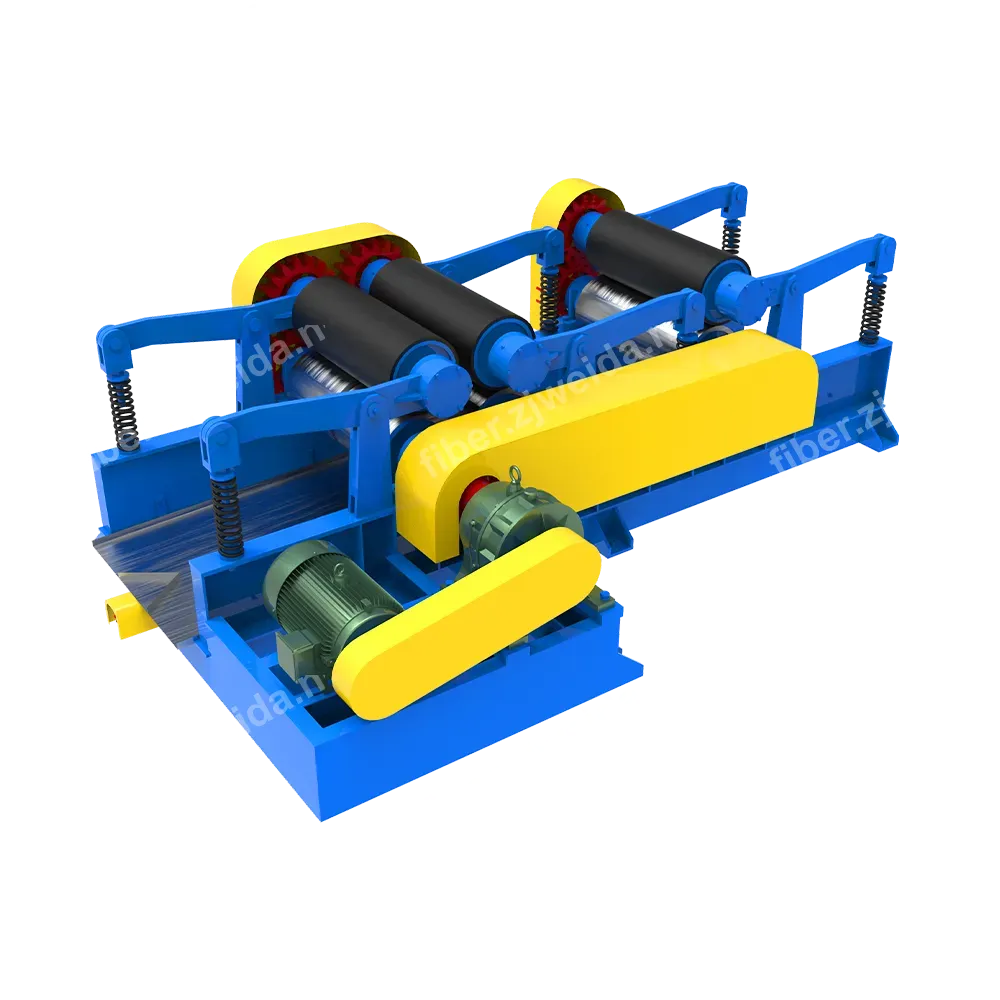

Main Components

- Screw Shaft

- Stainless Screen

- Pressure Adjustable Cone

- Reducer & Motor

Application Scenarios

Sisal Processing Plant

Recovering sisal juice for saponin or fertilizer.

Banana Fiber Plant

Recovering banana juice, reducing wastewater.

Biomass Energy Plant

Pre-treating high-moisture biomass materials.

Recommended Matching Equipment

Tow Shaker

Separate loose fibers from waste before juicing to increase economic value.

| Model | JZ-450 / JZ-550 |

| Capacity | 5 - 10 Ton/Hour (Residue) |

| Juice Rate | ≥80% |

| Power | 15 kW - 18.5 kW |