Call Us

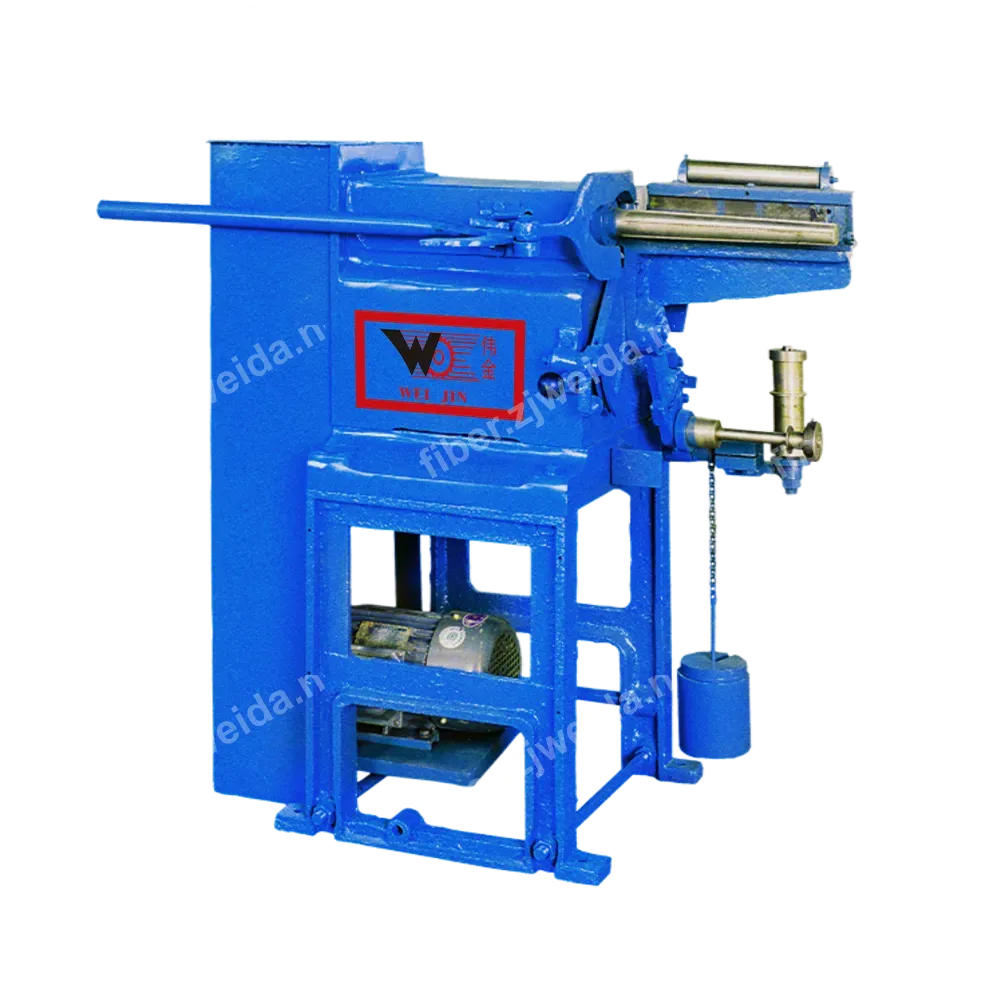

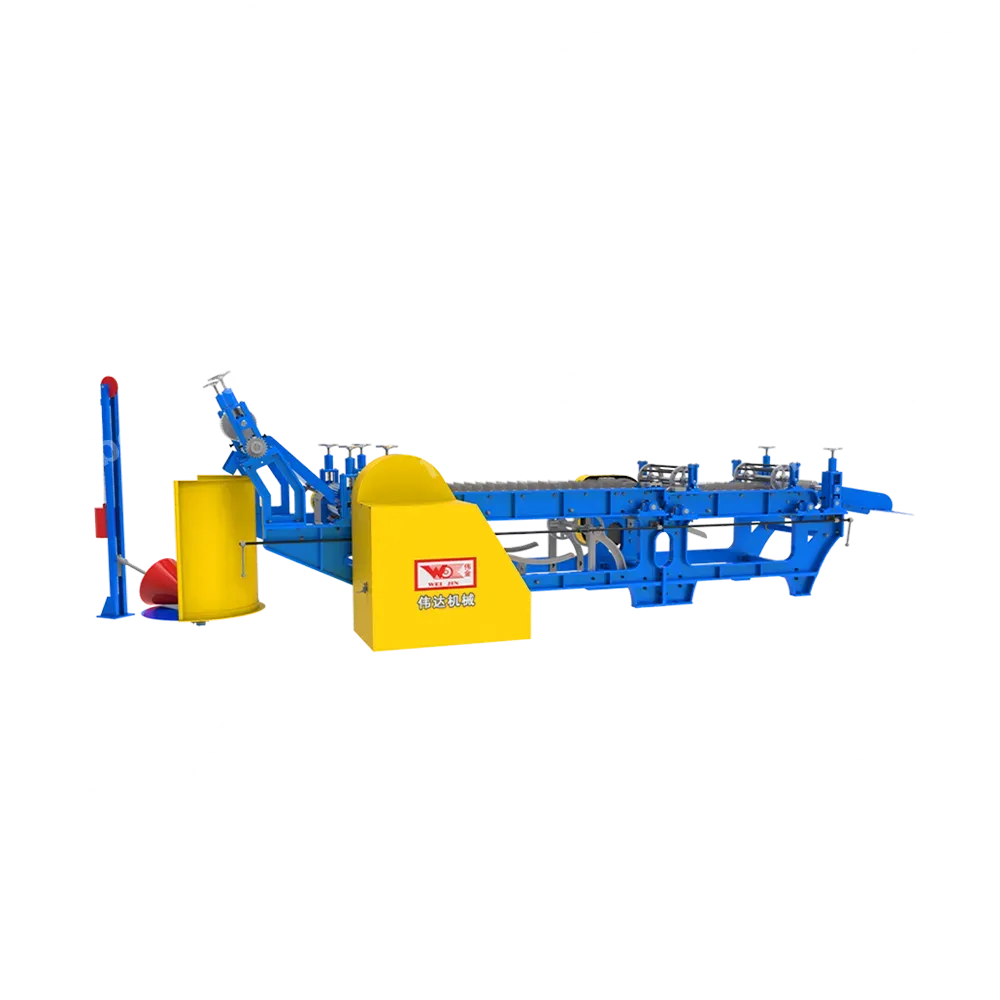

Sisal Combing Machine

The 'First Step' in rope making, combing loose fibers into uniform slivers ensuring rope strength and quality.

Key Highlights:

- Dual Pin Bar Combing: Cooperation of slow and fast pin bars to thoroughly straighten fibers.

- Multi-Stage Drafting: Roller drafting structure ensures uniform sliver thickness and consistency.

- Automatic Coiling: Combed slivers are automatically coiled into balls for easy handling.

- Specialized Design: Designed specifically for sisal rope manufacturing, mature and stable process.

Product Overview

LJ Series Sisal Combing Machine (Drawing Frame First Stage) is the first process equipment in sisal rope manufacturing. Its function is to process loose long fibers from circular combing machines into continuous, uniform 'Slivers' through pin bar combing and roller drafting. This step is decisive for the evenness and strength of subsequent yarns. Usually divided into No.1 Combing Machine (First Stage) and No.3 Combing Machine (Second Stage) for progressive refinement.

Why Choose Us

'Fast & Slow Pin Bar' Composite Process

Equipped with slow and fast pin bars internally. As fibers pass between them, the speed difference creates a drafting effect, straightening fibers, making them parallel, and removing residual short fibers.

Multi-Stage Roller Conveyance

Includes feed rollers, drafting rollers, and delivery rollers, forming a stable drafting channel. Ensures output sliver weight deviation is small and structure is tight.

High Output & Durable

Pins and fallers made of special steel, wear-resistant. High production efficiency, single machine output 300-700kg/hour, meeting large-scale factory needs.

Adjustable Specs

Sliver weight (g/m) can be adjusted according to target rope thickness, covering 40-360g/m range.

Process Flow

- 1.Manual Spreading: Spread weighed loose fibers evenly in feed hopper.

- 2.Feed Combing: Feed rollers send fibers into pin bar zone.

- 3.Drafting & Straightening: Pin bars and drafting rollers straighten and combine fibers.

- 4.Sliver Coiling: Output slivers pass through coiling device into large balls.

- 5.Transfer: Sliver balls transferred to next drawing frame.

Main Components

- Feed Rollers

- Gill Box - Slow & Fast

- Drafting Rollers

- Coiling Head

- Drive System

Application Scenarios

Sisal Rope Factory

Producing white coir rope, sisal wire rope cores, etc.

Carpet Yarn Factory

Producing sisal carpet yarns.

Recommended Matching Equipment

Circular Combing Machine

Upstream process.

Drawing Frame

Downstream process.

| Model | LJ-25.4 (1st Stage) / LJ-12.0 (2nd Stage) |

| Capacity | 300 - 700 kg/h |

| Sliver Spec | 100 - 360 g/m |

| Power | 4 kW - 7.5 kW |

| Weight | 4.6 Ton - 7.2 Ton |