Call Us

Sisal Automatic Fiber Extraction Line

Fully automatic fiber extraction solution designed for scale sisal processing, achieving high-efficiency continuous production from fresh leaf input to clean fiber output.

Key Highlights:

- Efficient Synergy: Smooth connection of conveying, arraying, decortication, and dewatering processes.

- Full Line Automation: High degree of automation, core equipment requires only 2-3 operators (excluding auxiliary labor).

- High Quality Output: Double-drum decortication + spray washing produces clean, good-colored fiber.

- Stable & Durable: Designed for tropical high-load conditions, offering strong operational stability.

Product Overview

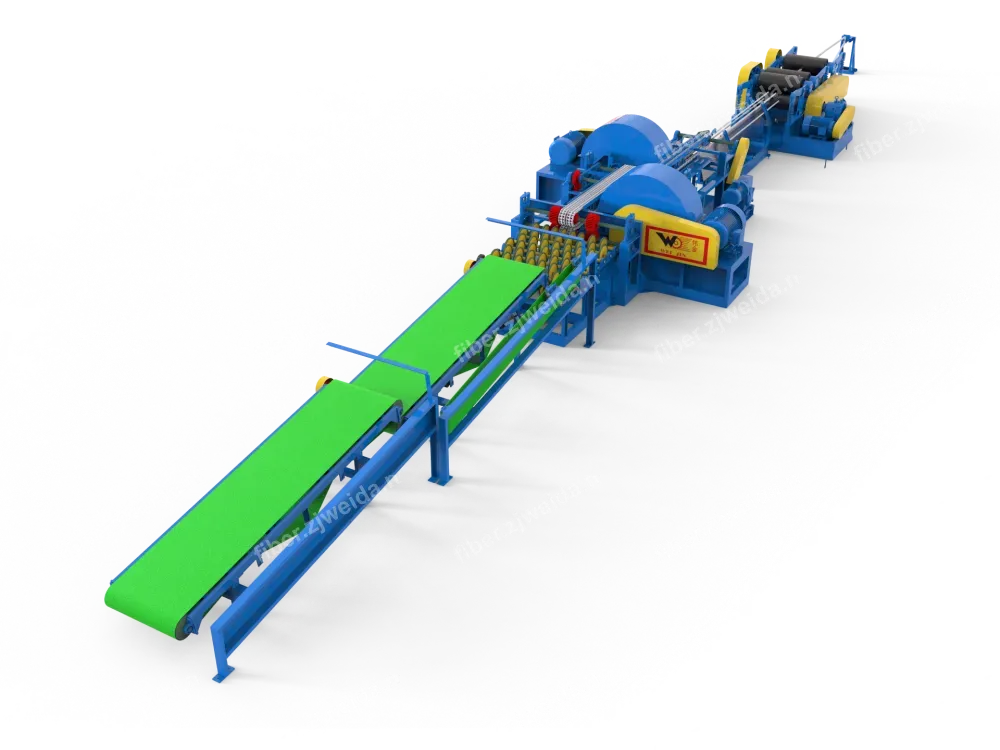

SGMX-1300 Sisal Automatic Fiber Extraction Line is a large-scale complete sisal fiber extraction equipment developed by Weida Machinery based on years of industry experience. This production line is designed to solve pain points such as low efficiency, high labor intensity, and unstable fiber quality in traditional sisal processing. The line adopts an integrated system design, deeply integrating four core modules: belt conveying, automatic arraying, double-drum fiber extraction, and fiber dewatering. It achieves a continuous "Automatic Feeding - Efficient Decortication - Washing - Preliminary Dewatering" process, helping to improve production efficiency and fiber quality, making it an ideal solution for modern large-scale sisal fiber processing factories.

Why Choose Us

High Automation, Reduced Labor Reliance

Through dial conveying and swing arraying technology, automatic and orderly leaf entry is achieved. The core equipment of the entire line requires only 2-3 people to monitor and maintain (excluding auxiliary personnel for raw material feeding and product collection), helping to reduce reliance on skilled workers and optimize labor costs.

Double-Drum Decortication, Excellent Extraction

The main machine uses a double-drum structure combined with high-speed rotating curved blades, scraping the base first and then the tip. This progressive processing helps improve fiber extraction rates while protecting fiber length as much as possible, reducing damage.

Integrated Washing & Dewatering, Superior Quality

Connected with a fiber dewatering module at the rear, equipped with a professional spray system and strong pressure rollers. It performs washing and dewatering immediately while extracting fiber, removing leaf juice, sugar, and surface gum, producing clean, loose fiber, laying a good foundation for subsequent processing.

Rugged & Durable, Adapted to Complex Environments

Considering the high temperature and high humidity environment of main sisal production areas, core components of the entire line (such as chains, belts, blades) are selected from wear-resistant and corrosion-resistant materials with a sturdy structural design, ensuring long-term stability under continuous operation.

Process Flow

- 1.Material Conveying: Belt conveyors smoothly feed bundled or loose fresh sisal leaves.

- 2.Automatic Arraying: Arraying mechanism automatically unbundles and organizes leaf orientation to ensure uniform feeding.

- 3.Double-Stage Decortication: Double-drum main machine precisely scrapes the leaf base and tip in sequence, separating fiber from flesh.

- 4.Washing & Dewatering: Fiber enters the dewatering machine directly, washed of sugar by spray water, and squeezed of most moisture by rubber rollers.

- 5.Finished Output: Clean semi-dry fiber is output, ready for drying or baking.

Main Components

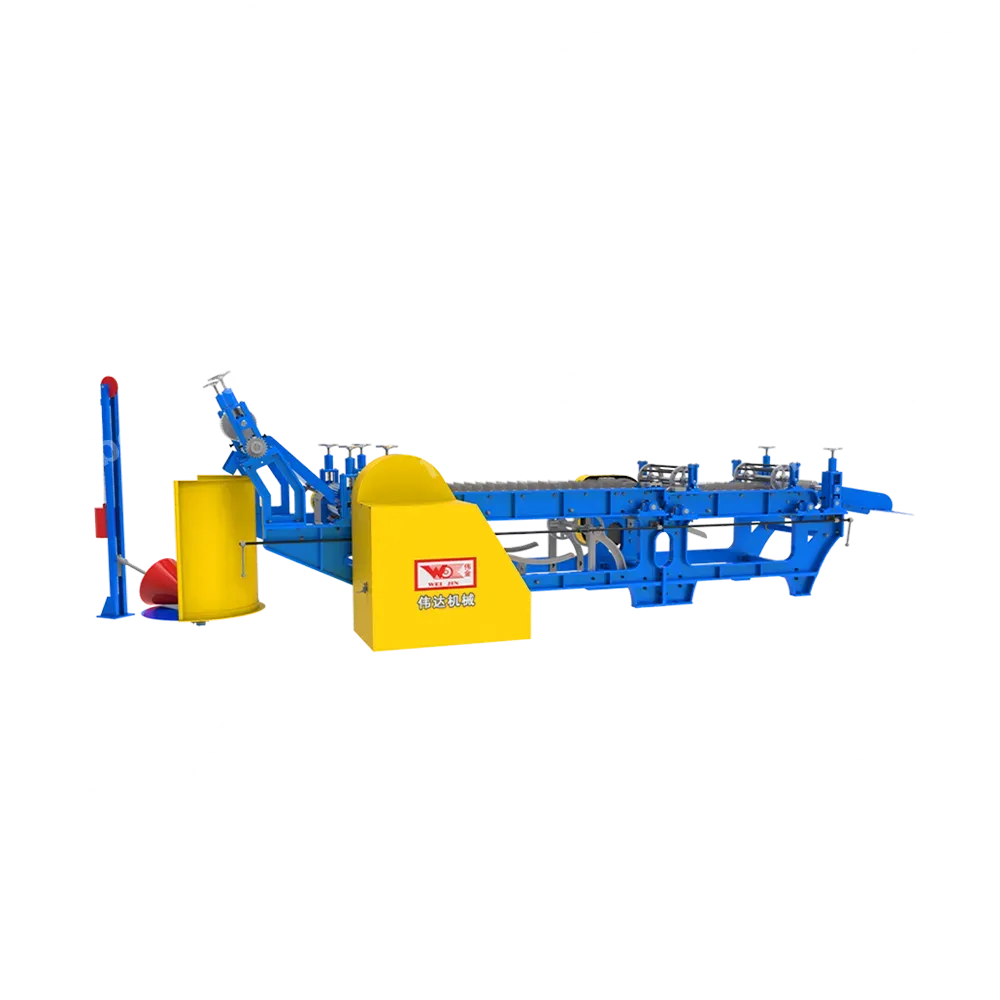

- Belt Conveyor * 2pcs

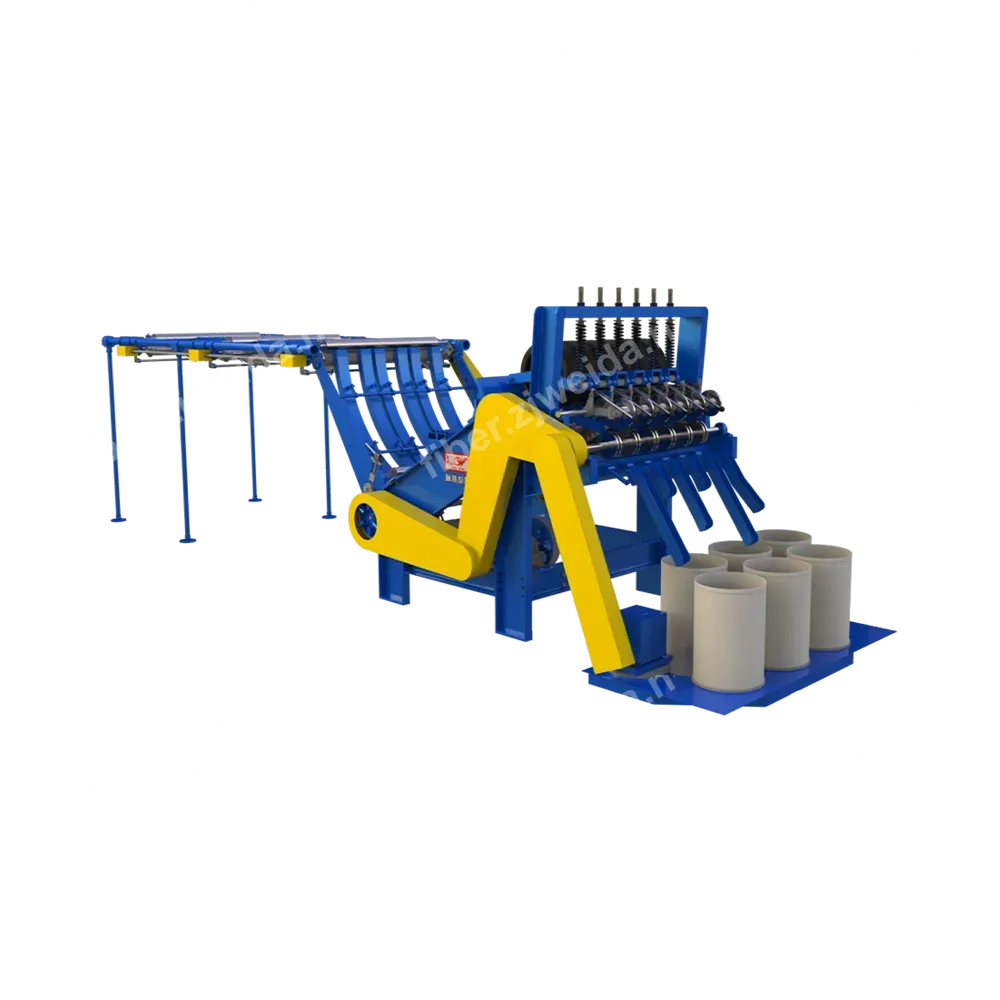

- Arraying Machine

- Twin Drum Decorticator

- Dewatering Machine

- Control Box

Application Scenarios

Large Sisal Plantations

Suitable for bases with over 1000 acres of planting scale for centralized high-efficiency processing.

Scale Fiber Processing Factories

Suitable for enterprises specializing in natural fiber extraction and primary processing, meeting large order production needs.

Recommended Matching Equipment

Fiber Brushing Machine

For deep physical cleaning of sun-dried sisal fiber. Through multiple combing rollers, it effectively removes residual skin fragments, dust, and short fluff, significantly improving fiber cleanliness, luster, and smoothness to meet export-grade high-quality standards.

Fiber Baling Machine

Vertical hydraulic baling equipment designed for plant fibers. Compresses fluffy dry fiber into tight, regular square bales (usually 100-250kg/bale), greatly saving storage space and reducing long-distance transport costs.

Waste Juice Extractor

Key equipment for green recycling. Spiral presses the moisture-rich waste residue generated during decortication to recover plant juice as high-quality foliar fertilizer raw material or bio-energy raw material, while the dewatered dry residue is easier to compost or process, reducing environmental pollution.

Tow Shaker Machine

Used to recover effective fiber from production line waste. Through physical screening and vibration structure, it separates messy hemp and short fibers mixed in the residue, turning waste into treasure and maximizing raw material utilization rate.

| Model | SGMX-1300 |

| Raw Material | Sisal Leaf |

| Design Capacity | 5 T/h (Fresh Leaf Processing) |

| Core Process | Double-Drum Decortication + Spray Washing + Roller Dewatering |

| Control System | Centralized Frequency Control Box |

| Installation Dimensions | Approx 20.3m × 4m × 1.6m |

| Total Weight | Approx 11 Tons |