Nullam dignissim, ante scelerisque the is euismod fermentum odio sem semper the is erat, a feugiat leo urna eget eros. Duis Aenean a imperdiet risus.

Nullam dignissim, ante scelerisque the is euismod fermentum odio sem semper the is erat, a feugiat leo urna eget eros. Duis Aenean a imperdiet risus.

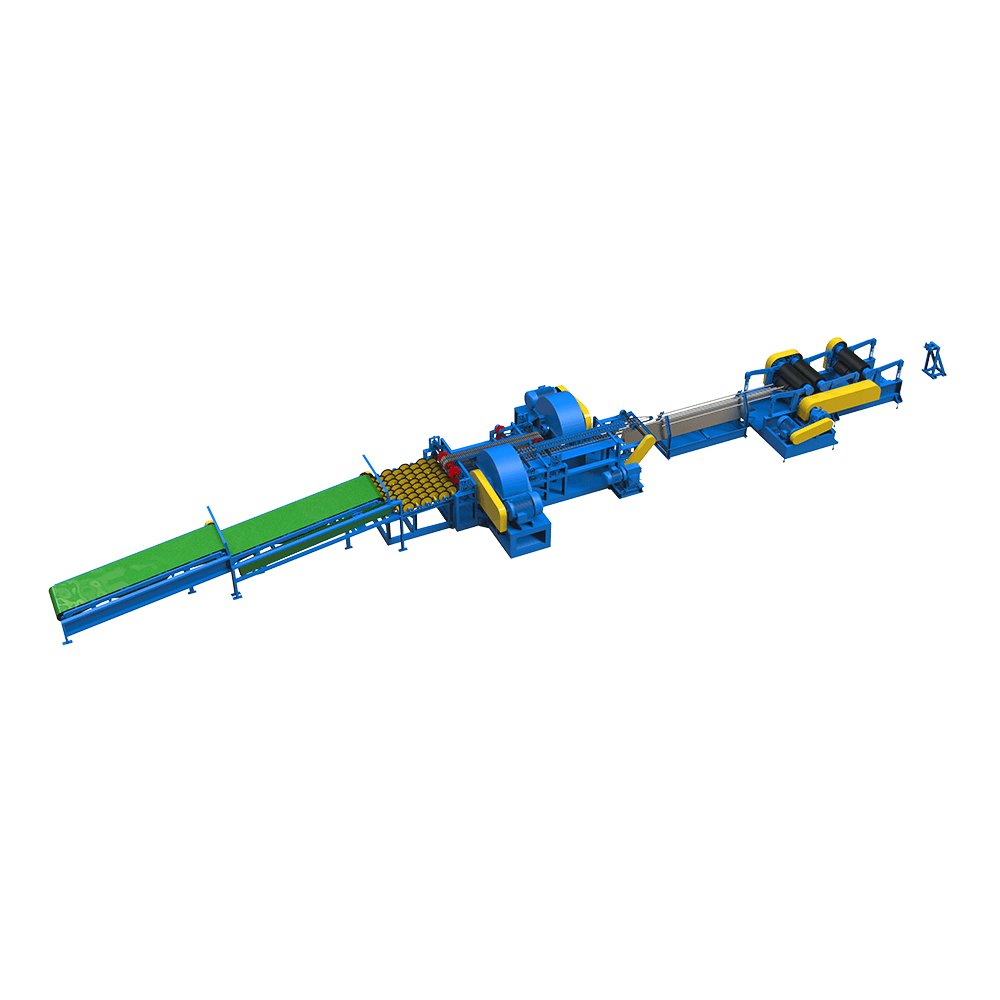

A new integrated automatic line combining automatic feeding, fiber extraction, washing, and dewatering — an ideal solution for achieving high efficiency, low cost, and high cleanliness in sisal fiber production.

Sisal Automatic Decorticator SGMX-1300 is a new type of fiber extraction equipment, including two units of belt conveyors, a unit of arraying machine, a unit of two‑side drum extraction main machine, and a unit of fiber pressing machine. It enables automatic feeding, fiber extraction, washing, and dehydration. This set of equipment features low labor intensity, high production efficiency, low production cost, and good fiber cleanliness.

A complete process chain (automatic feeding → extraction → washing → dewatering) significantly reduces labor intensity and energy consumption, meeting modern large‑scale production needs.

Q1: What are the main advantages of the SGMX‑1300 line compared with traditional decorticators?

Automation and integration. It achieves automatic feeding to reduce manual handling, and integrates washing and dewatering to improve fiber cleanliness and significantly shorten subsequent drying time.

Q2: How is sisal fiber cleanliness ensured?

The dual‑drum extraction main machine enables efficient separation; the fiber pressing machine with spray cleaning and mechanical pressing dewatering deeply removes residual pith and sap to ensure high cleanliness.

Q3: Is maintenance and replacement of consumables convenient?

The structure is rational and key components are wear‑resistant. We provide a consumables list and replacement guidance to ensure long‑term stable operation.

Q4: What are the main application fields of extracted sisal fibers?

High‑strength ropes, marine cables, industrial brushes, carpets, automotive interior parts, and various composite materials.