Call Us

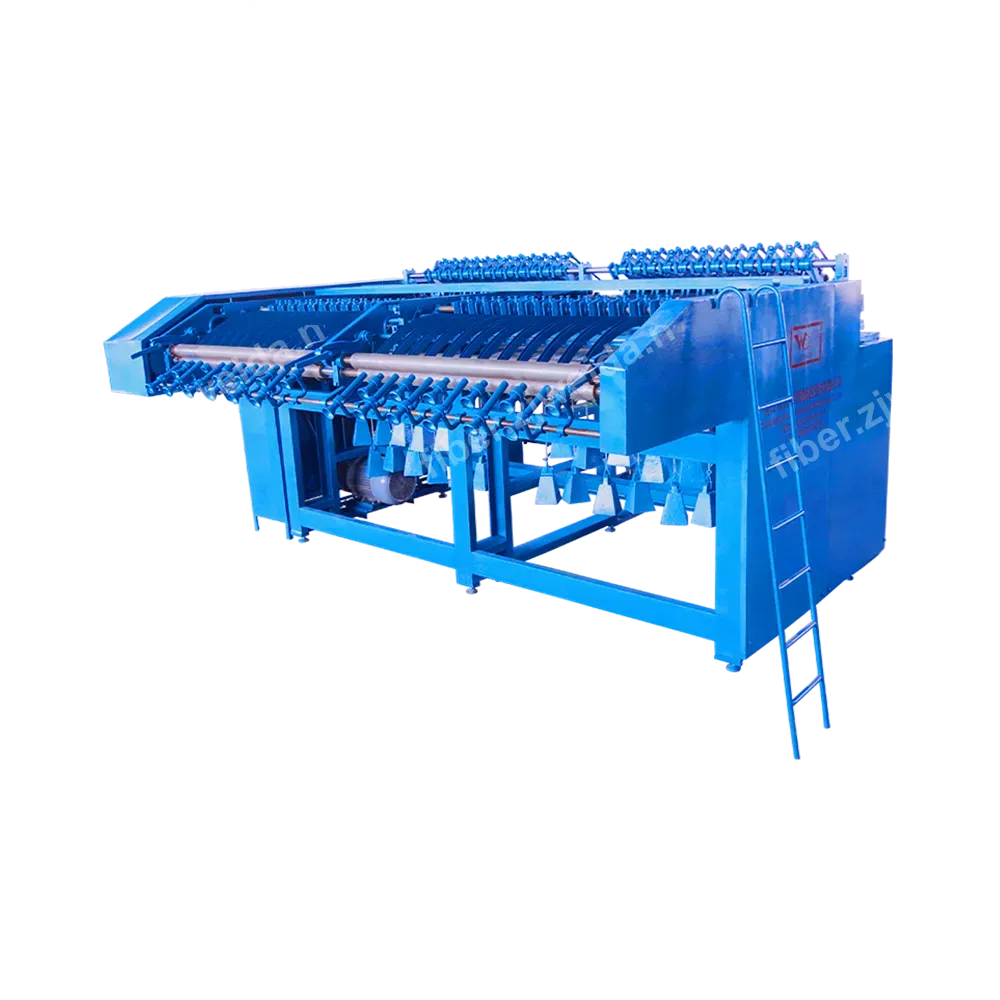

Short Fiber Willowing Machine

Powerful opening, efficient impurity removal, giving new life to waste short fibers.

Key Highlights:

- High-Speed Opening: 2350rpm high-speed pinned drum instantly breaks up knotted fibers.

- Centrifugal Cleaning: Uses high-speed rotation centrifugal force to automatically eject sand, dust, and hard impurities.

- Safe Feeding: Roller feeding design, safe operation, uniform intake.

- Strong Adaptability: Compatible with coir, palm, sisal tow, hemp waste, and other short fibers.

Product Overview

DSL Series Short Fiber Willowing Machine (also Carding Machine) is mainly used for processing short (5-50mm) or tangled plant fibers. Examples include Coir, Oil Palm Fiber (EFB), and Sisal processing waste (Tow). These materials often contain dust and are intertwined. This machine uses high-speed rotating toothed drums to tear and comb the material, making it loose and fluffy while removing most non-fiber impurities. It is essential pre-processing equipment for short fiber rope making or mattress filling.

Why Choose Us

Integrated 'Feeding-Willowing-Cleaning'

Combines uniform feeding, powerful willowing, and automatic impurity removal. Material is opened and purified in a very short time, efficient and simple.

Pinned Drum Precision Willowing

The core component is a drum covered with steel pins. Designed for short fibers, it effectively breaks down hard knots and clumps without excessively cutting fibers.

Centrifugal Auto-Purification

Using the strong centrifugal force from high-speed rotation (approx. 2350 rpm), heavier impurities (sand, shell bits) are thrown out through the screen, while lighter fibers are blown out, achieving physical separation.

High Output, Low Energy

Single machine capacity up to 1-1.5 tons/hour with only 15-18kW power, high energy efficiency suitable for large-scale waste recycling.

Process Flow

- 1.Manual Feeding: Put compressed or loose short fibers into feed hopper.

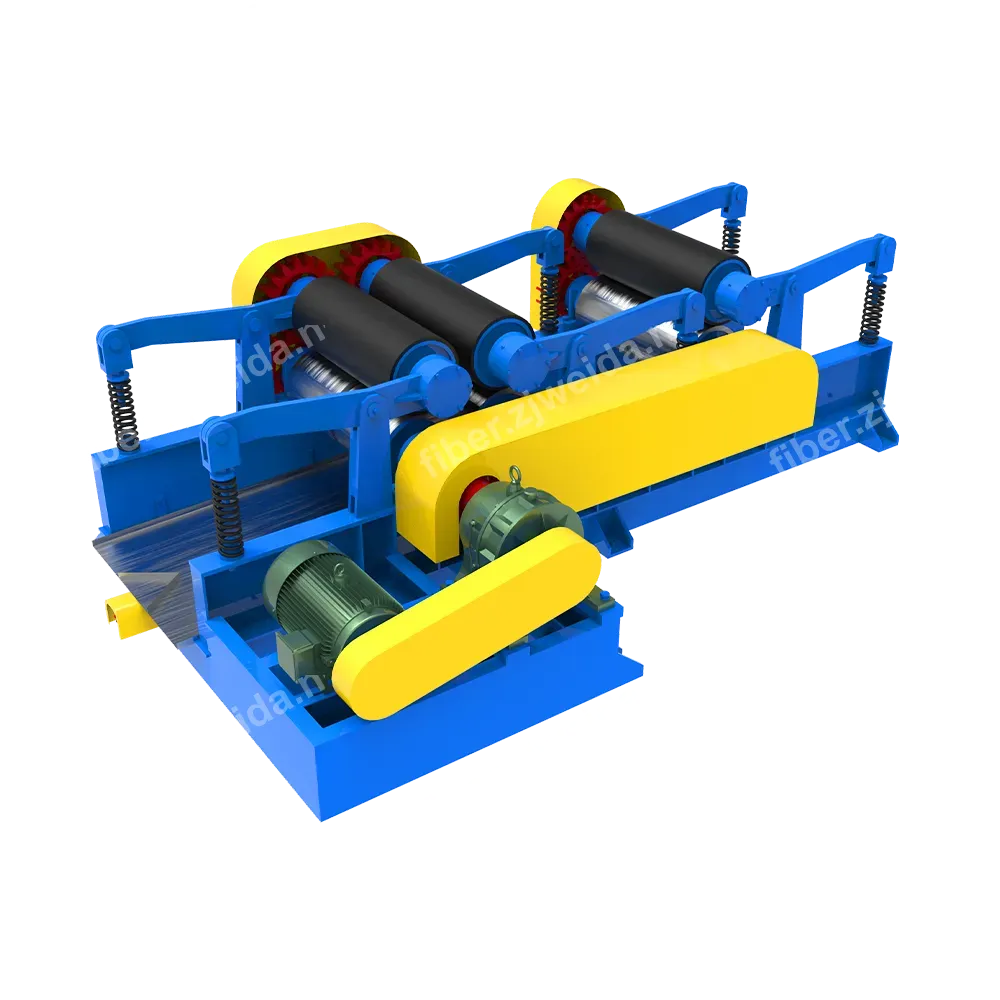

- 2.Roller Feeding: Feeding rollers send material uniformly into willowing chamber.

- 3.High-Speed Willowing: Pinned drum strikes and combs fibers at high speed.

- 4.Impurity Separation: Impurities discharged through bottom screen.

- 5.Output: Fluffy clean fibers ejected from outlet.

Main Components

- Feeding Mechanism

- Pinned Drum

- Screen

- Motor & Drive

- Frame

Application Scenarios

Coir Mattress Factory

Processing coir material.

Short Fiber Rope Factory

Providing loose material for rope machines.

Hemp Mill

Recycling short tow from combing machines.

Recommended Matching Equipment

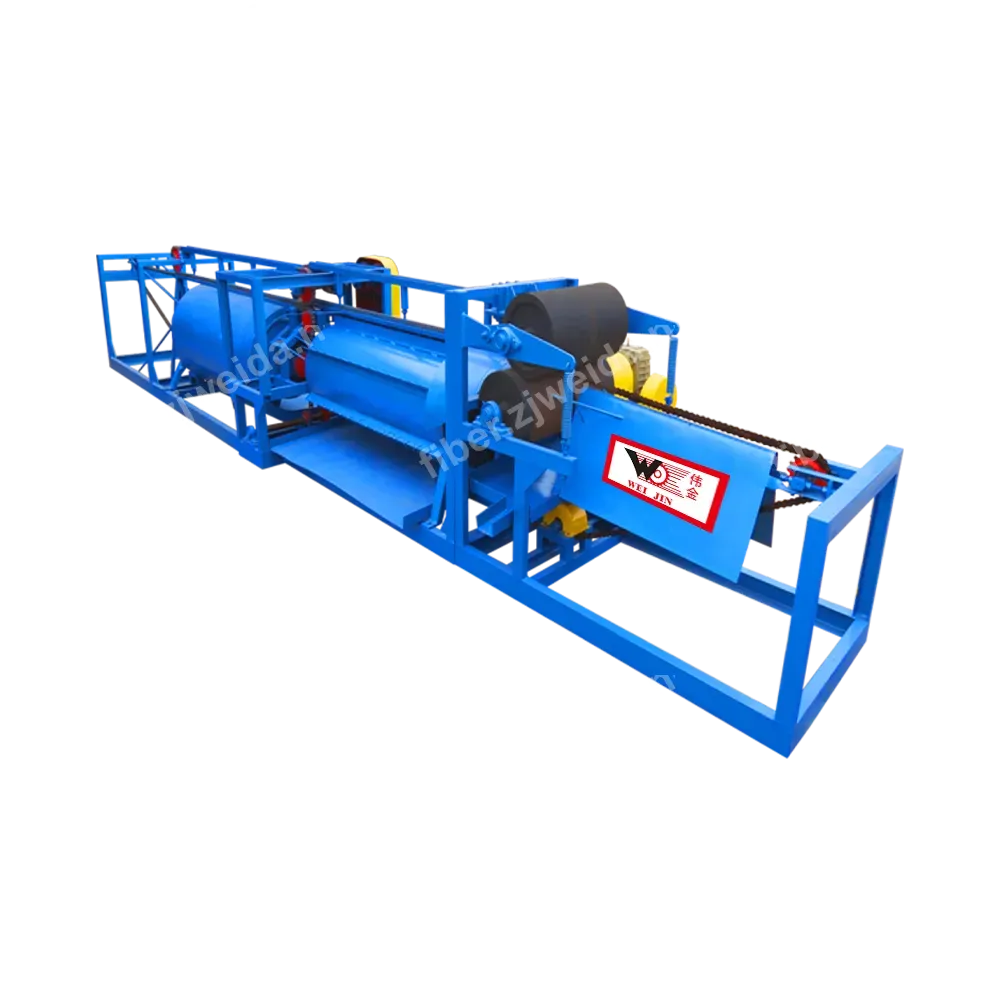

Short Fiber Rope Making Machine

Downstream equipment.

Baling Machine

Baling fluffy fibers.

| Capacity | 1.0 - 1.5 Ton/Hour |

| Fiber Length | 5-50 mm |

| Fluffiness | ≥85% |

| Drum Speed | 2350 rpm |

| Power | 15 kW / 18 kW |

| Dimensions | 3200*1700*2200 mm / 3500*1800*2400 mm |