Call Us

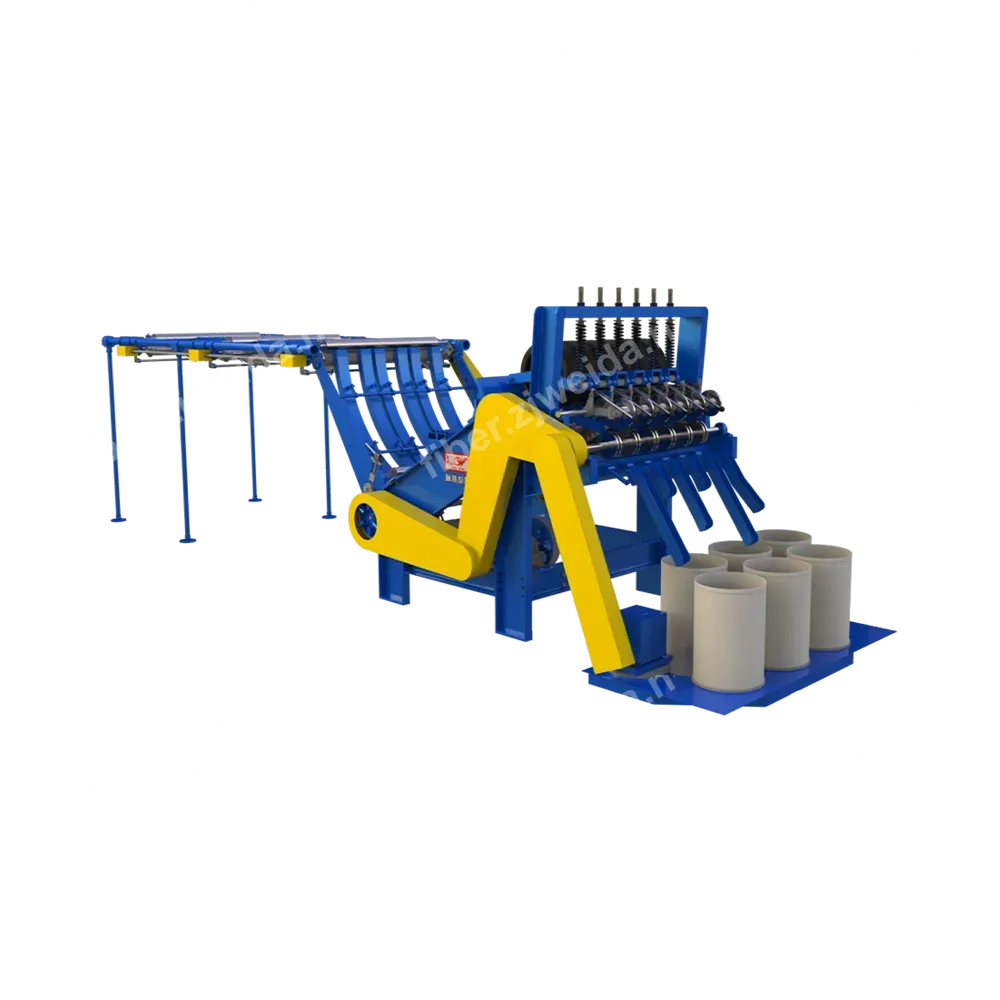

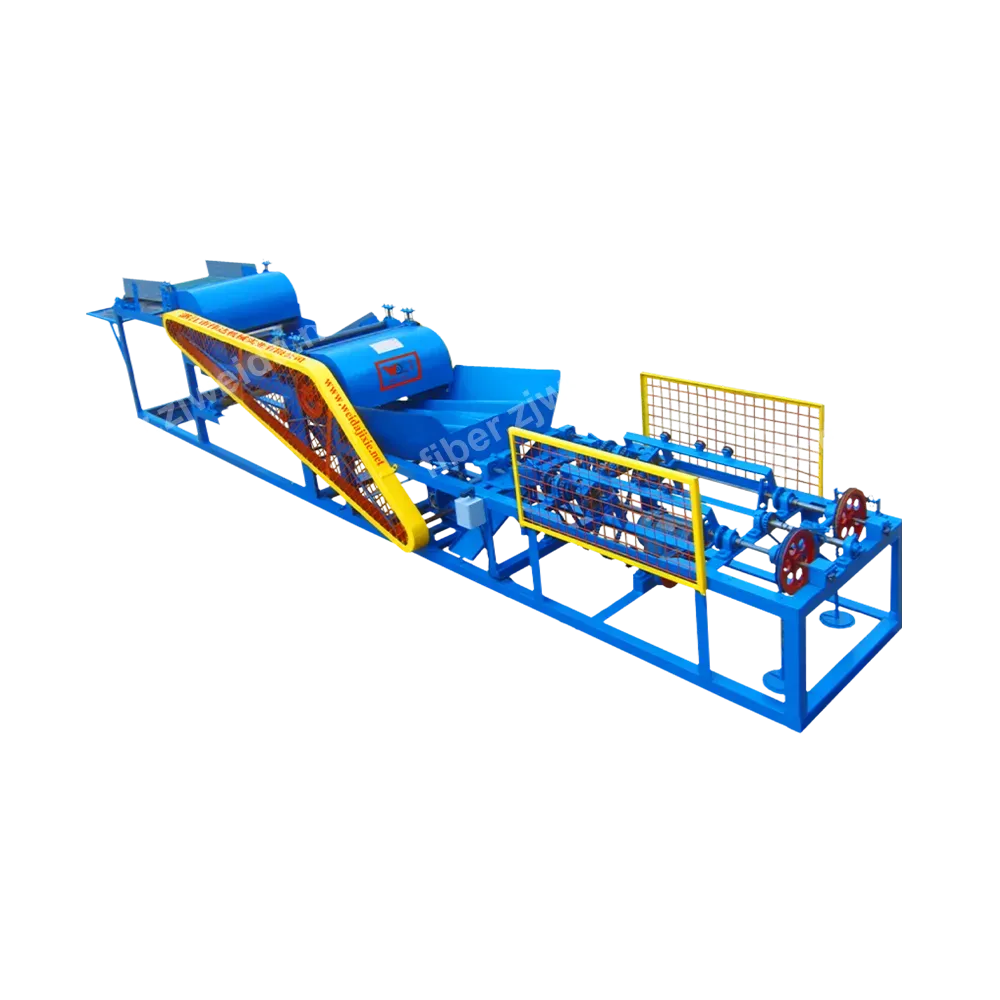

Short Fiber Rope Making Machine

Transform waste short fibers into high-value ropes, fully automatic integrated rope making, simple operation, high return.

Key Highlights:

- Fully Integrated Process: Complete process from loose fiber to finished rope in one machine (Combing-Stranding-Twisting-Coiling).

- Waste Utilization Expert: Perfectly adapted for low-value materials like coir, palm, and sisal tow.

- 2-Ply / 3-Ply Options: Produce 2-ply or 3-ply ropes as needed, adjustable rope diameter 4-10mm.

- Labor & Power Saving: Power only 0.75kW, one person can manage multiple machines.

Product Overview

The DSH Series Short Fiber Rope Making Machine is Weida Machinery's specialized equipment for short fiber resource utilization. Traditional long fiber rope machines cannot handle short fibers (5-15cm) like coir or oil palm silk. This machine solves this problem with a unique progressive combing and twisting structure. It processes these short fibers, which would otherwise be fuel or waste, into ropes with specific strength, widely used in gardening, crafts, and oyster farming.

Why Choose Us

Progressive Combing Process

Built-in front and rear combing wheels. Material undergoes initial loosening then secondary fine combing. This ensures short fibers are fully opened and evenly mixed, forming the basis for continuous rope strands.

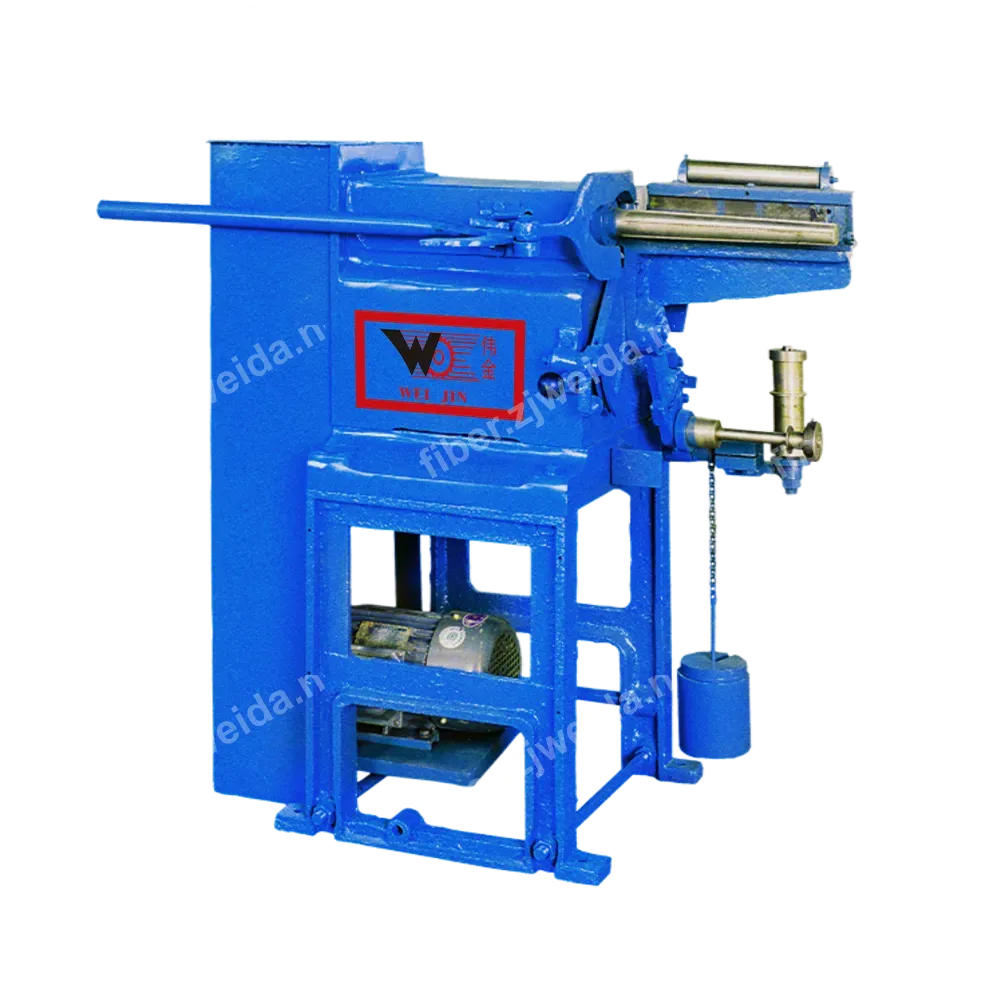

Spindle Twisting & Setting

Vertical spindle structure for strong twisting of stranded fibers. The twisted rope is tight, with effectively contained hairiness, good surface finish, and stable tensile strength.

High Automation

Operators only need to feed loose material into the inlet. The machine automatically handles conveying, splitting, strand making, twisting, and coiling. No complex threading or manual assistance needed, greatly lowering the technical barrier.

Significant Economic Benefits

Extremely low raw material cost (often waste), low energy consumption (0.75kW), stable market demand for finished ropes, and very high ROI.

Process Flow

- 1.Manual Feeding: Put short fibers into the feed hopper.

- 2.Dual Stage Combing: Front and rear combing wheels loosen and straighten fibers.

- 3.Conveying & Splitting: Conveyor sends fibers to splitting hopper, dividing into 2 or 3 strands.

- 4.Strand Forming: Fiber bundles pass through strand nozzles to form initial strands.

- 5.Twisting & Roping: Spindles rotate to twist strands together into rope.

- 6.Automatic Coiling: Finished rope is automatically wound into coils.

Main Components

- Combing Head

- Conveyor Belt

- Splitting Device

- Twisting Spindle

- Coiling Reel

Application Scenarios

Coir Processing Plant

Producing Coir Rope.

Sisal Farm

Producing binding ropes from processing waste.

Gardening Supply Factory

Producing biodegradable plant fiber ropes.

Recommended Matching Equipment

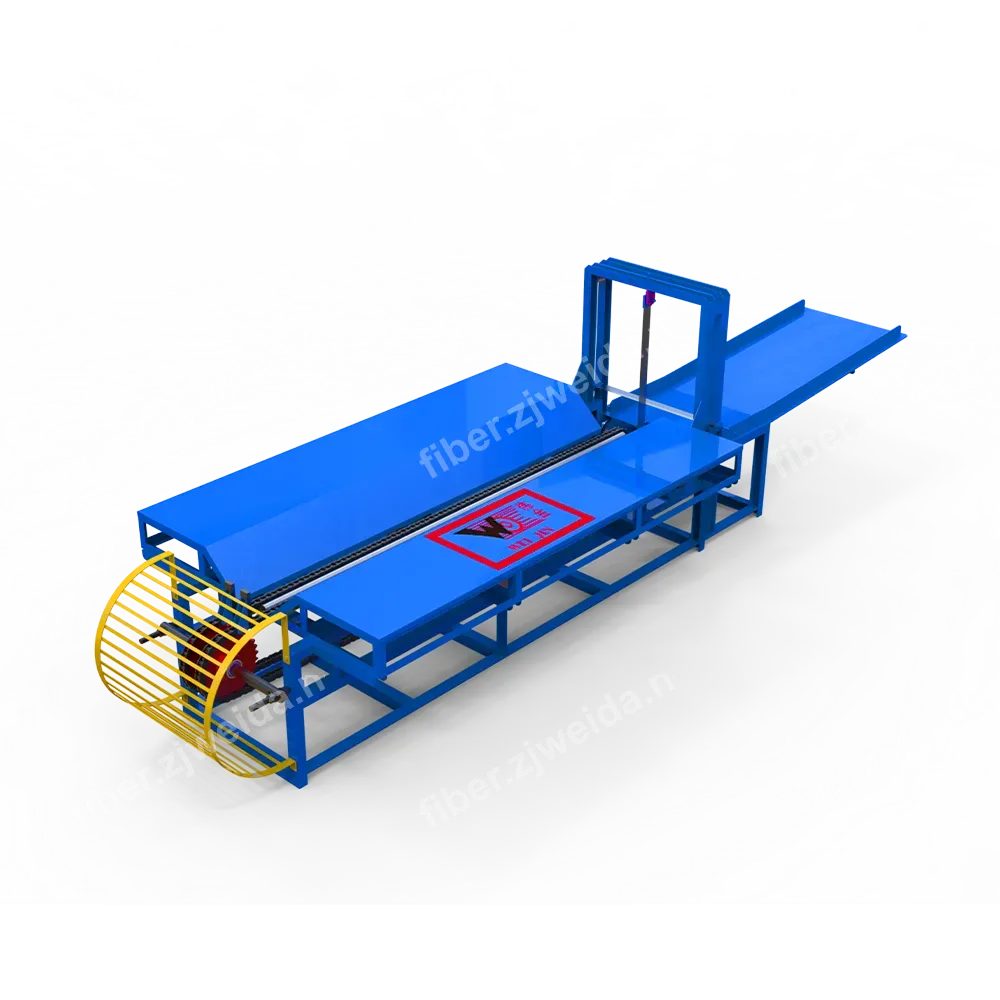

Short Fiber Willowing Machine (DSL Series)

If material is too compacted, use willowing machine first.

| Rope Strands | 2 Ply / 3 Ply |

| Rope Diameter | 4-10 mm |

| Speed | Approx. 30 m/min |

| Power | 0.75 kW |

| Dimensions | 3825*815*915 mm / 4800*900*1030 mm |

| Weight | 450 kg / 480 kg |