Call Us

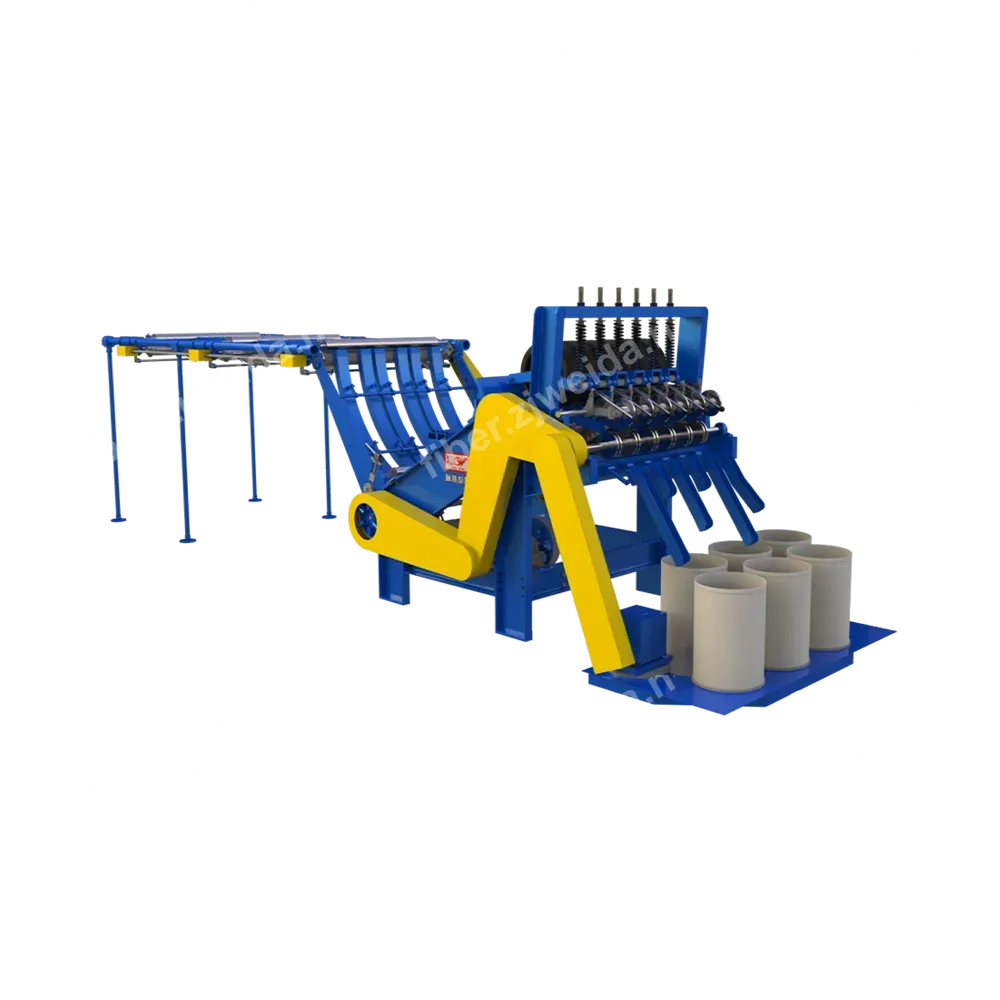

Semi Automatic Decorticator (Diesel/Electric)

Classic durable 'Reverse Pull' decorticator, built for harsh environments, diesel option available, the top choice for mobile processing in tropical regions.

Key Highlights:

- Dual Power Options: Available with diesel engine or electric motor, solving power supply issues in remote areas.

- Multi-Purpose: One machine for multiple materials, capable of processing sisal, pineapple leaf, banana stem, etc.

- Robust & Durable: Blade wheel with wear-resistant alloy overlay welding, thick frame, strong impact resistance.

- Flexible & Portable: Compact size, moderate weight, easy to load and transfer, high mobility.

Product Overview

GM-400 and XT-250 are classic semi-automatic reverse pull fiber extraction machines (also known as 'Hand-Fed Decorticators'). This model has an extremely simple and reliable structure, breaking leaf pulp via high-speed rotating blade wheels. Operators feed half of the material manually, pull it out after scraping, then turn it around to feed the other half. Although it requires some manual skill, it is extremely popular in Africa and Southeast Asia due to its adaptability, low failure rate, and independence from power grids.

Why Choose Us

Operation in Non-Electric Areas

Standard with diesel engine base and transmission interface. In fields without 3-phase power, a single diesel engine can drive the machine at full load, enabling on-site processing.

'Blade Wheel + Fixed Blade' Composite Process

Blade wheel designed with special angles, cooperating with adjustable fixed blade plate. Extracts fiber from tough sisal or soft pineapple leaves with minimal damage and controllable cleanliness.

Extremely Low Maintenance Cost

Almost no complex wear parts. Worn blades can be sharpened or repaired by welding, requiring very low maintenance skills, suitable for areas with poor repair conditions.

High Cost-Effectiveness

Low equipment cost, short payback period, the first choice for startup planters or small-scale processors.

Process Flow

- 1.Startup: Start diesel engine or motor, wait for stable speed.

- 2.Feed Head: Hold leaf tail, feed head into scraping opening for blade wheel processing.

- 3.Reverse Pull: After head is scraped, pull it out forcefully (using centrifugal force and skill).

- 4.Feed Tail: Hold the scraped fiber part, feed the unscraped tail.

- 5.Full Exit: After tail is scraped, pull out to complete extraction of the whole leaf.

- 6.Collect: Place wet fiber aside.

Main Components

- Blade Wheel

- Fixed Blade Plate

- Diesel Engine / Motor

- Guard & Feeding Inlet

Application Scenarios

Power-Deficient Plantations

Such as remote farms in Africa.

Scattered Planters

Field processing of leaves after pineapple harvest.

Initial Startup

Limited funds, need low investment start.

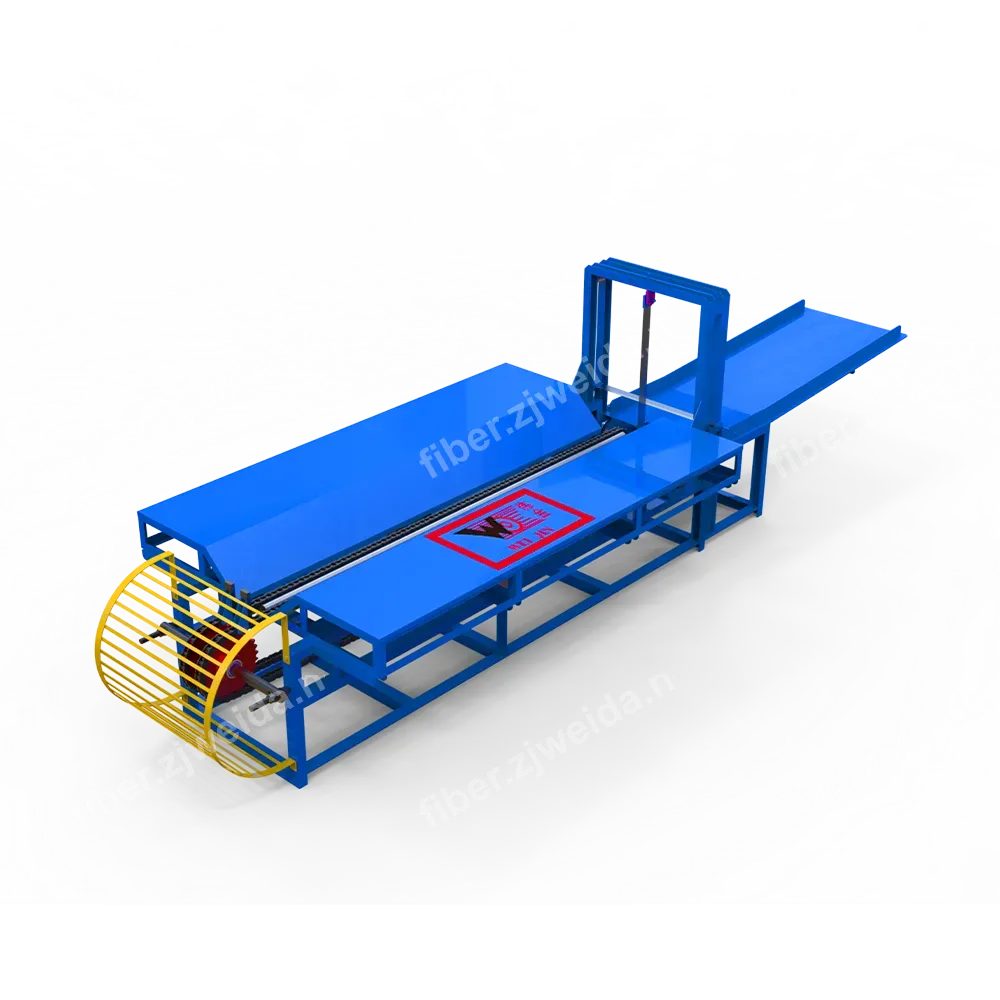

Recommended Matching Equipment

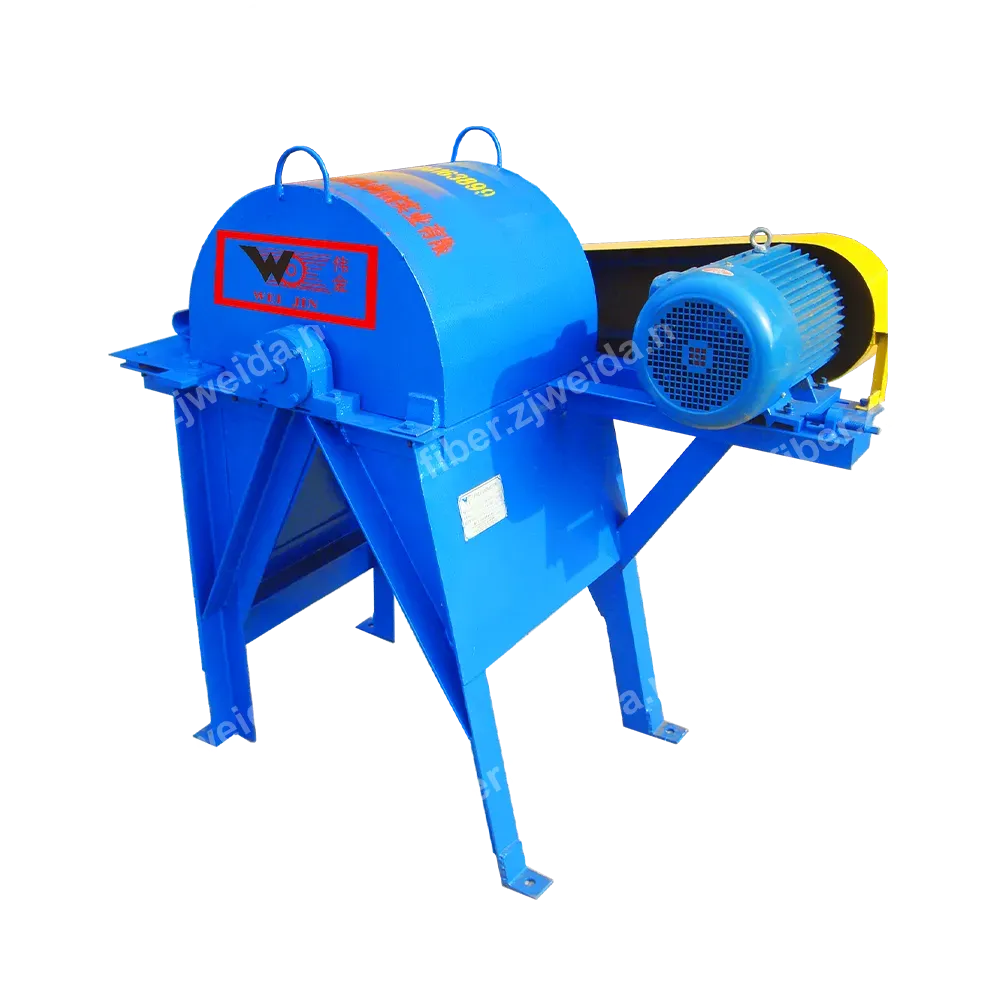

Diesel Engine

Common power source.

Fiber Dewatering Machine

Semi-automatically extracted fiber has high moisture, dewatering is recommended.

| Model | GM-400 (Standard) / XT-250 (Light) |

| Capacity | 0.2 - 1 Ton/Hour (Fresh Leaf) |

| Blade Wheel Speed | 1050 - 1650 r/min |

| Power Configuration | 2.2-7.5KW Motor / 4-12HP Diesel Engine |