Call Us

Hemp & Jute Automatic Fiber Extraction Line

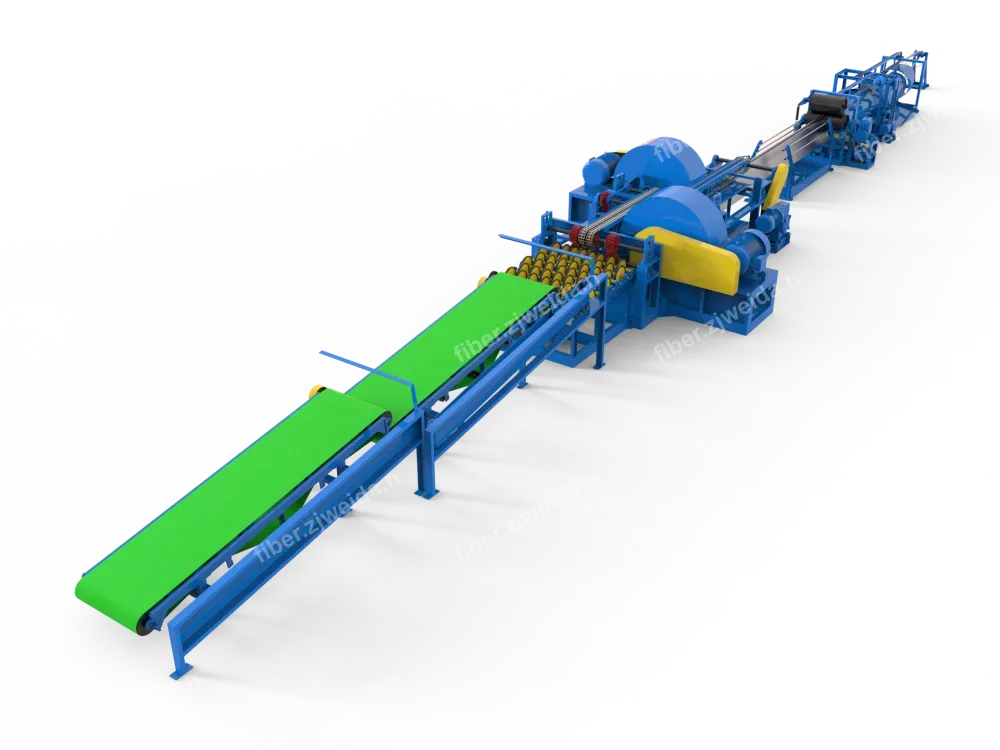

Fully automatic processing solution designed for bast fibers (Hemp, Jute, Kenaf, etc.), efficiently separating fiber from core to produce high-quality raw fiber.

Key Highlights:

- Multi-Variety Adaptation: Compatible with various bast fibers like Industrial Hemp, Kenaf, Ramie, Sunn Hemp, and Jute.

- Efficient Separation: Thorough separation of fiber and core, Extraction rate ≥90%, Fiber cleanliness increased by 25%.

- Full Process Automation: Equipped with automatic arraying, double-drum extraction, washing & polishing, requiring only 2-3 operators.

- High Quality Output: Fiber damage rate ≤5%, preserving natural fiber strength and length.

Product Overview

HGMX-1300 Hemp & Jute Automatic Fiber Extraction Line is a large-scale complete processing equipment developed by Weida Machinery specifically for Bast Fiber characteristics. Unlike leaf fibers, bast fibers require effective separation of the phloem (fiber) from the xylem (core). This production line employs double-drum automatic decortication technology combined with specialized peeling processes, achieving fully automatic continuous operation from raw stalk input to clean fiber output, completely changing the low efficiency, heavy pollution, and high labor intensity of traditional retting or manual peeling.

Why Choose Us

High Automation, Reduced Labor Costs

Through dial conveying and swing arraying technology, automatic and orderly stalk entry is achieved. The core equipment of the entire line requires only 2-3 people to monitor and maintain, significantly reducing labor costs.

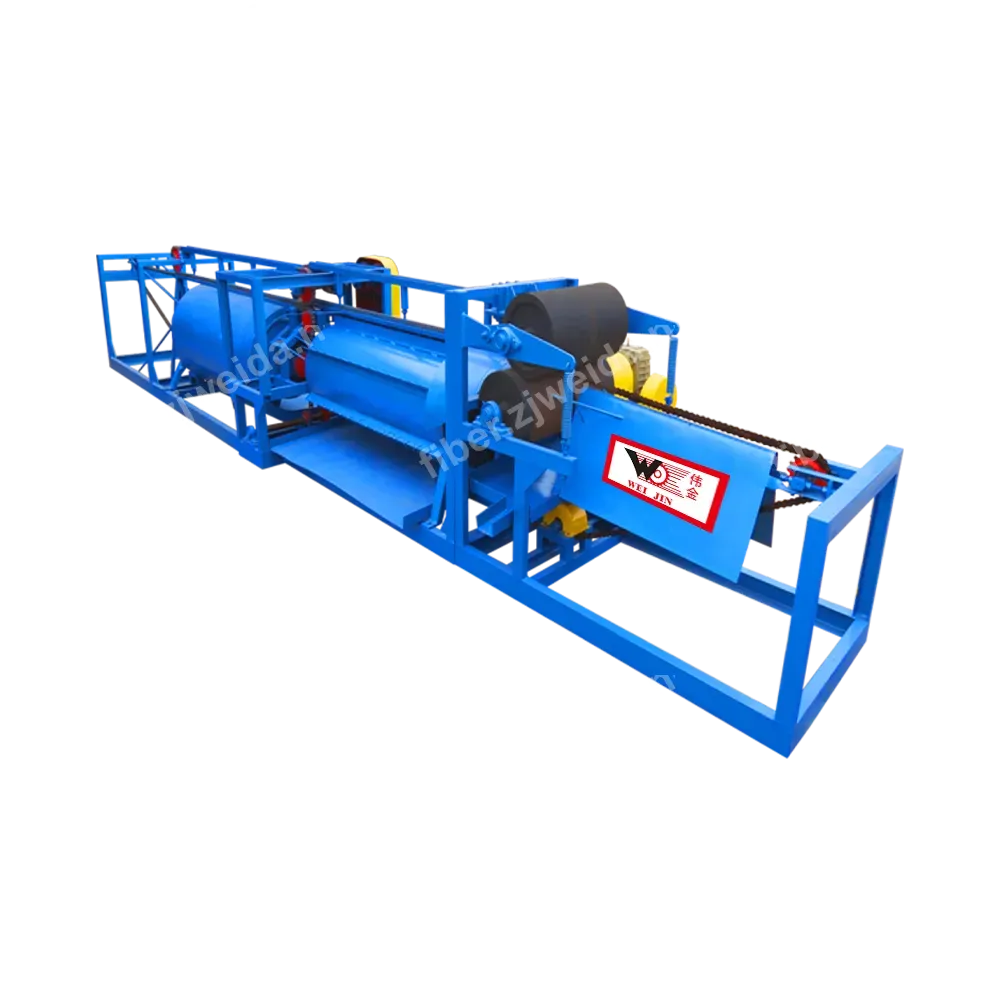

Double-Drum Decortication, Excellent Separation

The main machine uses a double-drum structure with high-speed rotating curved blades, scraping the base first and then the tip. This progressive processing effectively shatters the stalk core, thoroughly separating the fiber from the core while protecting the fiber from damage.

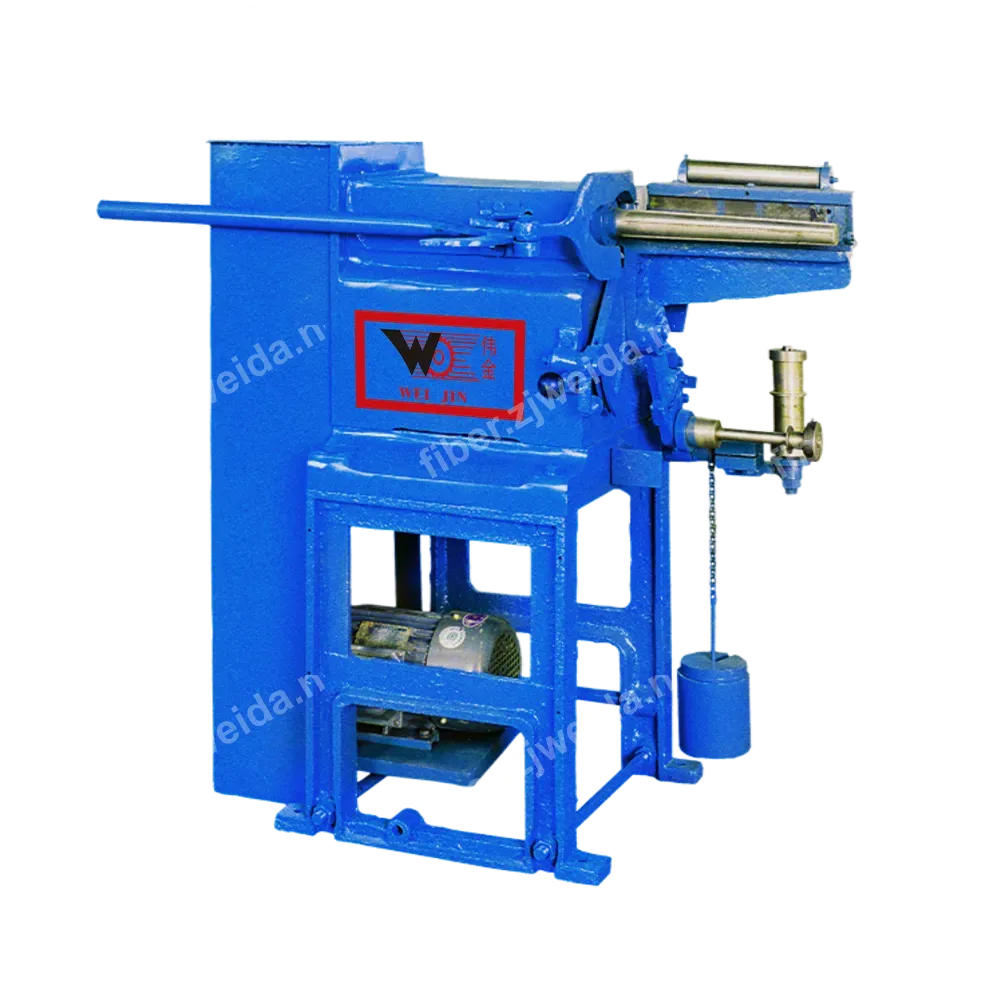

Integrated Washing & Polishing, Quality Enhancement

Connected with a fiber dewatering and polishing machine at the rear. It performs water spraying cleaning and roller polishing while extracting fiber, removing gum and residual woody matter from the fiber skin, making the fiber cleaner, looser, and smoother.

Rugged & Durable, Strong Adaptability

Core components are made of wear-resistant materials with a sturdy structural design, adapted to high-load continuous production. Optimized specifically for working conditions in hemp growing areas for stable operation.

Process Flow

- 1.Material Unbundling: Unbundle the harvested hemp stalks.

- 2.Manual Layout: Spread the stalks flat on the conveyor belt.

- 3.Automatic Conveying & Arraying: Equipment automatically organizes stalk orientation ensuring parallel entry.

- 4.Double-Stage Separation: First machine peels the base, second machine peels the tip; core is shattered and separated.

- 5.Washing & Polishing: Fiber enters downstream equipment for washing, dewatering, and polishing.

- 6.Finished Output: Clean hemp fiber is output for manual collection.

Main Components

- Belt Conveyors

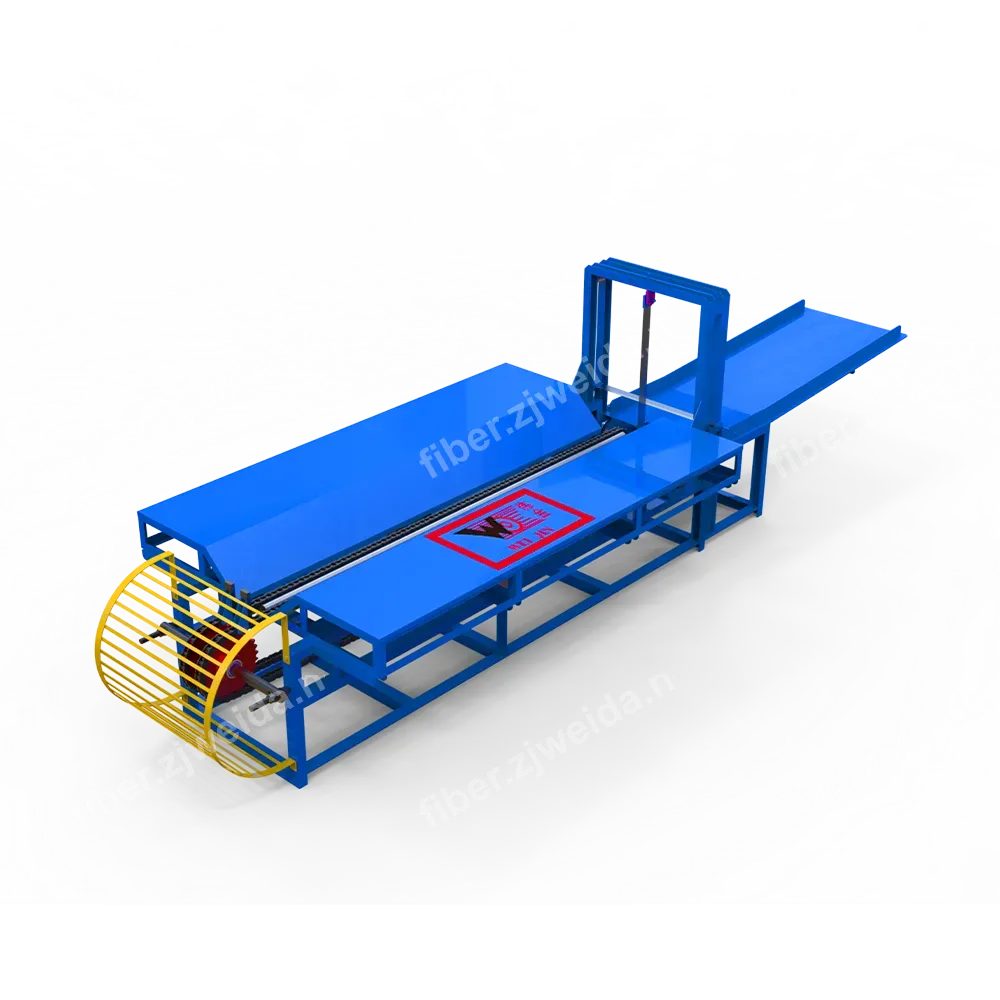

- Arraying Machine

- Double-Drum Extraction Machine

- Fiber Dewatering & Polishing Machine

- Control Box

Application Scenarios

Large Industrial Hemp Plantations

Suitable for fiber extraction of medicinal or industrial hemp.

Jute/Kenaf/Ramie Processing Factories

Suitable for large-scale primary processing of traditional textile fibers.

Recommended Matching Equipment

Round Combing Machine (YSJ-1200)

Used for fine combing and grading of hemp fibers, removing short fibers and impurities.

Fiber Baling Machine (XDB-120)

Compresses processed hemp fiber into bales for convenient transport and sales.

Fiber Brushing Machine (CZ1000 Series)

Further removes residual shives from the fiber.

| Model | HGMX-1300 |

| Raw Material | Industrial Hemp, Kenaf, Ramie, Sunn Hemp, Jute |

| Design Capacity | 3-5 T/h (Stalk Material) |

| Extraction Rate | ≥90% |

| Power | 81.35 kW (2.2+37+30+5.5+0.75+5.9) |

| Dimensions | Approx 20.3m × 4m × 1.6m |

| Total Weight | Approx 10 Tons |