Call Us

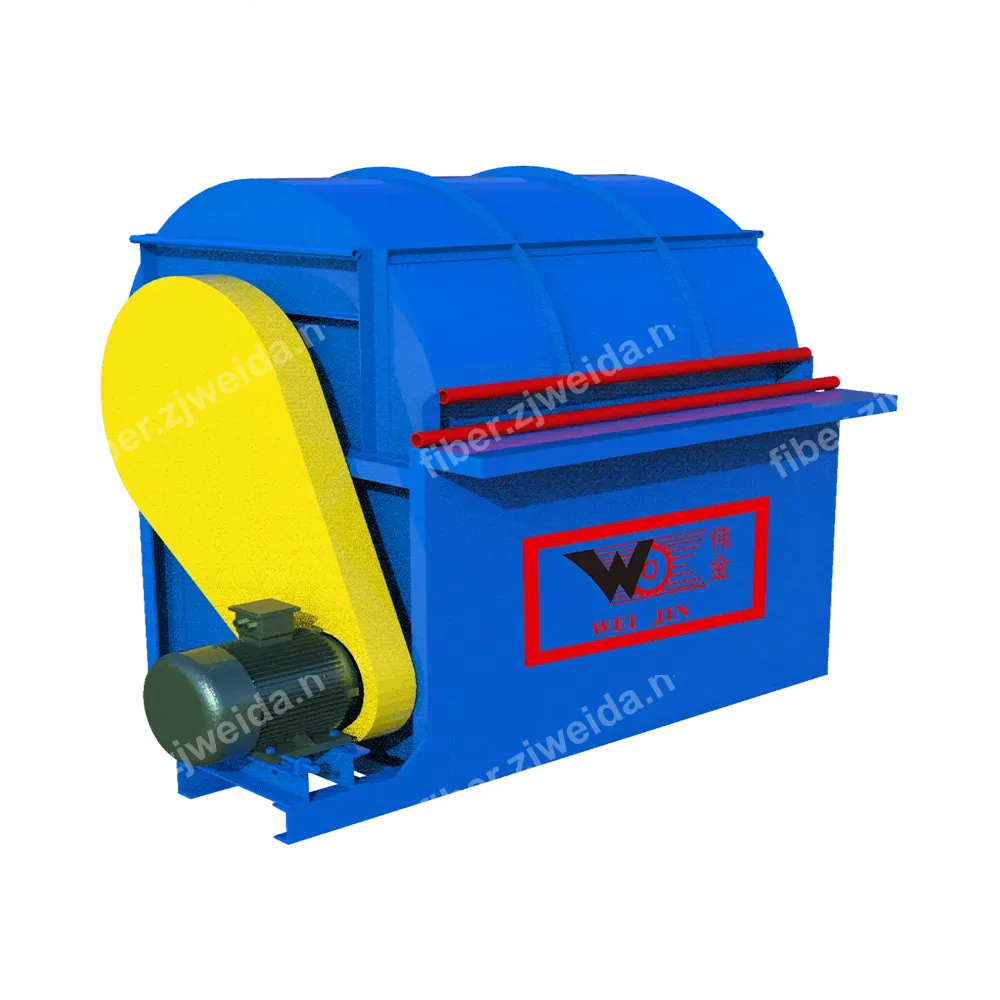

Fiber Dewatering Polishing Machine

Cleaning, dewatering, and polishing in one, solving sugar and moisture issues, laying the foundation for high-quality processing.

Key Highlights:

- 3-in-1 Process: Spray cleaning + Roller dewatering + Surface polishing, three steps in one machine.

- Efficient Dewatering: Moisture content ≤15% after pressing, greatly reducing drying time.

- Quality Enhancement: Effectively removes surface gums and sugars, preventing oxidation/discoloration, improving luster.

- Space Saving: Saves 40% space compared to separate equipment, lowers investment cost by 30%.

Product Overview

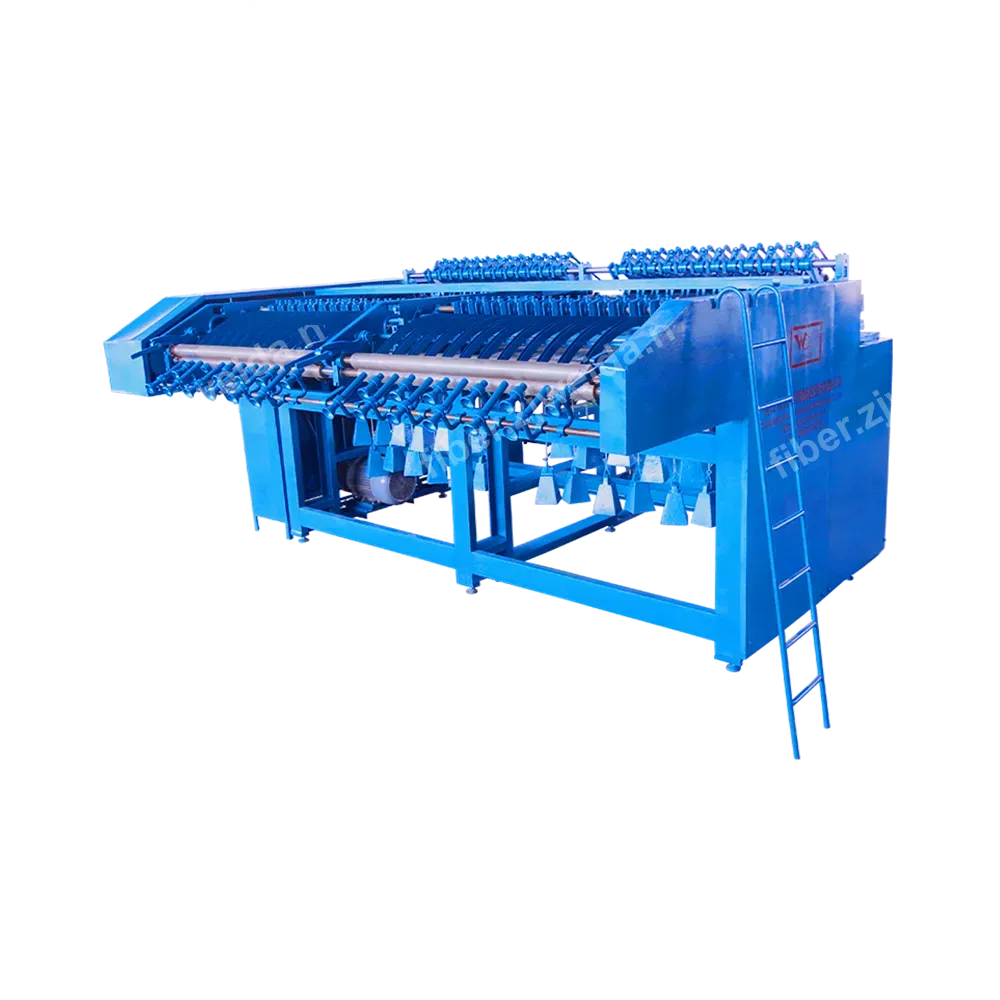

ZGA Series Fiber Dewatering Polishing Machine is key equipment connecting fiber extraction and drying/baling. Freshly extracted plant fibers (especially sisal, banana, pineapple leaf) contain acidic or sugary juices and high moisture. Direct drying leads to discoloration, mold, and slowness. This machine washes off juices via high-pressure spray, squeezes out water via strong rubber rollers, and organizes fibers via polishing rollers, making them semi-dry, clean, and loose before drying.

Why Choose Us

Integrated Process, Cost Efficiency

Replaces traditional 'Separate Wash Tank + Separate Dewaterer'. Fibers go directly from extractor to this machine, no manual transfer for washing, significantly reducing labor and water usage.

Deep Cleaning Spray System

Equipped with high-pressure spray system (w/ 3HP pump). Powerfully washes fiber surfaces, removing residual pulp and sticky pectin, key to ensuring white fiber color.

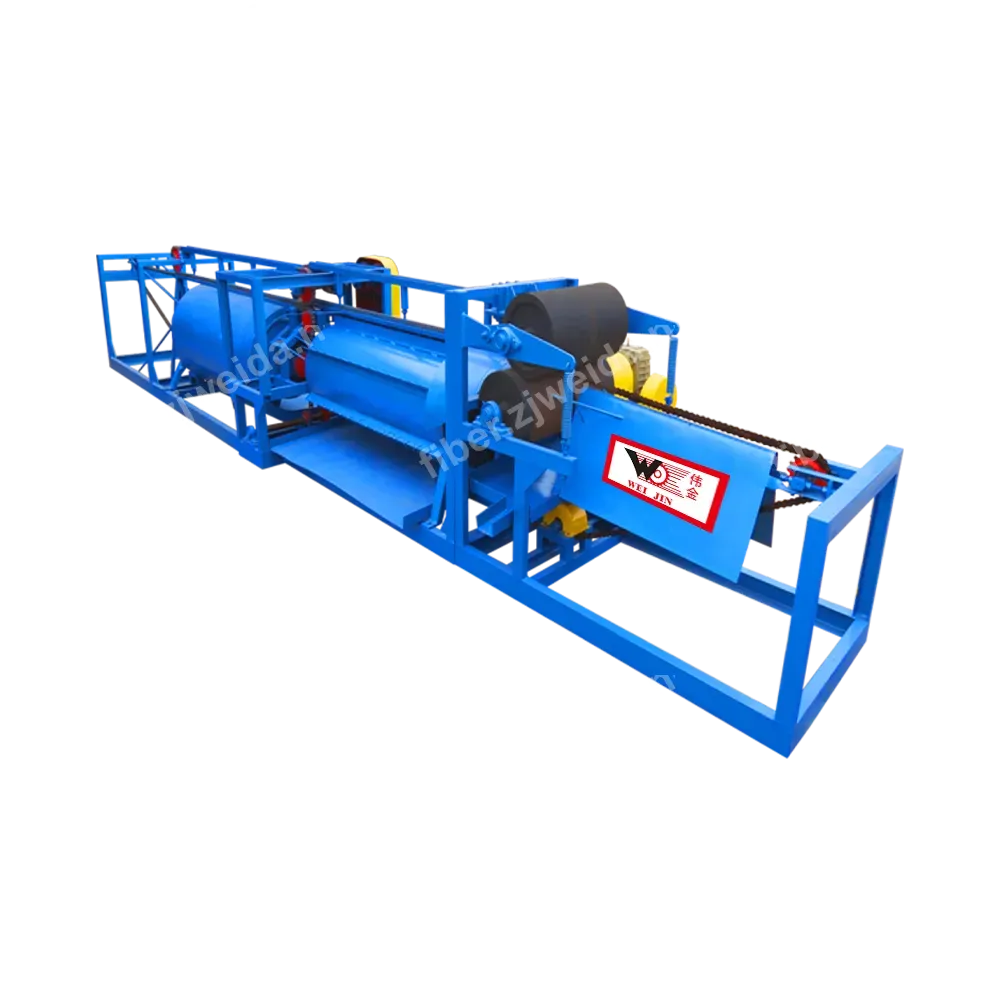

Strong Dewatering

Special rubber rollers reduce moisture to approx 15%. This saves drying space and significantly lowers energy costs for subsequent drying in rainy or humid areas.

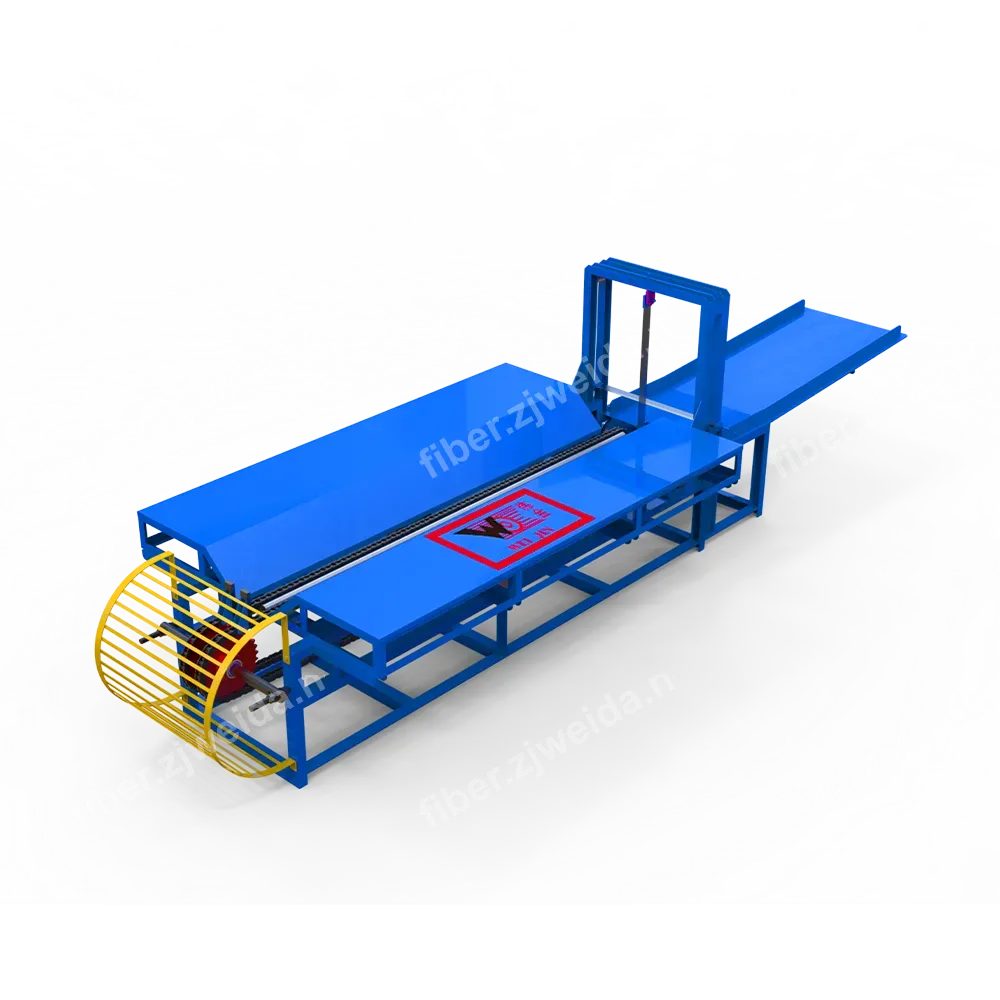

Polishing & Organizing

The terminal polishing structure loosens and combs flattened fibers, making them straighter and smoother, beneficial for downstream opening and combing.

Process Flow

- 1.Auto Reception: Receive wet fibers from upstream extractor.

- 2.Spray Cleaning: High-pressure water washes fibers, removing sugar and gum.

- 3.Roller Dewatering: Fibers pass through squeeze rollers, expelling most water.

- 4.Polishing: Polishing rollers friction and comb the fibers.

- 5.Output: Semi-dry fibers discharged for manual collection and drying.

Main Components

- Spray System

- Squeeze Rollers

- Polishing Mechanism

- Drive System

Application Scenarios

Fiber Extraction Line

Standard equipment following the decorticator.

High Quality Processing

For export-oriented enterprises requiring high color and strength standards.

Recommended Matching Equipment

Fiber Extraction Machine (SGMX/PGMX)

Core upstream equipment.

Fiber Dewatering Machine (YSJ)

Can be used in series if extreme dewatering is needed.

| Model | ZGA206 (Large/Double Polish) / ZGA204 (Medium) |

| Capacity | 2 - 4 Ton/Hour |

| Moisture After | ≤15% |

| Power | 3.7 kW - 5.9 kW |