Call Us

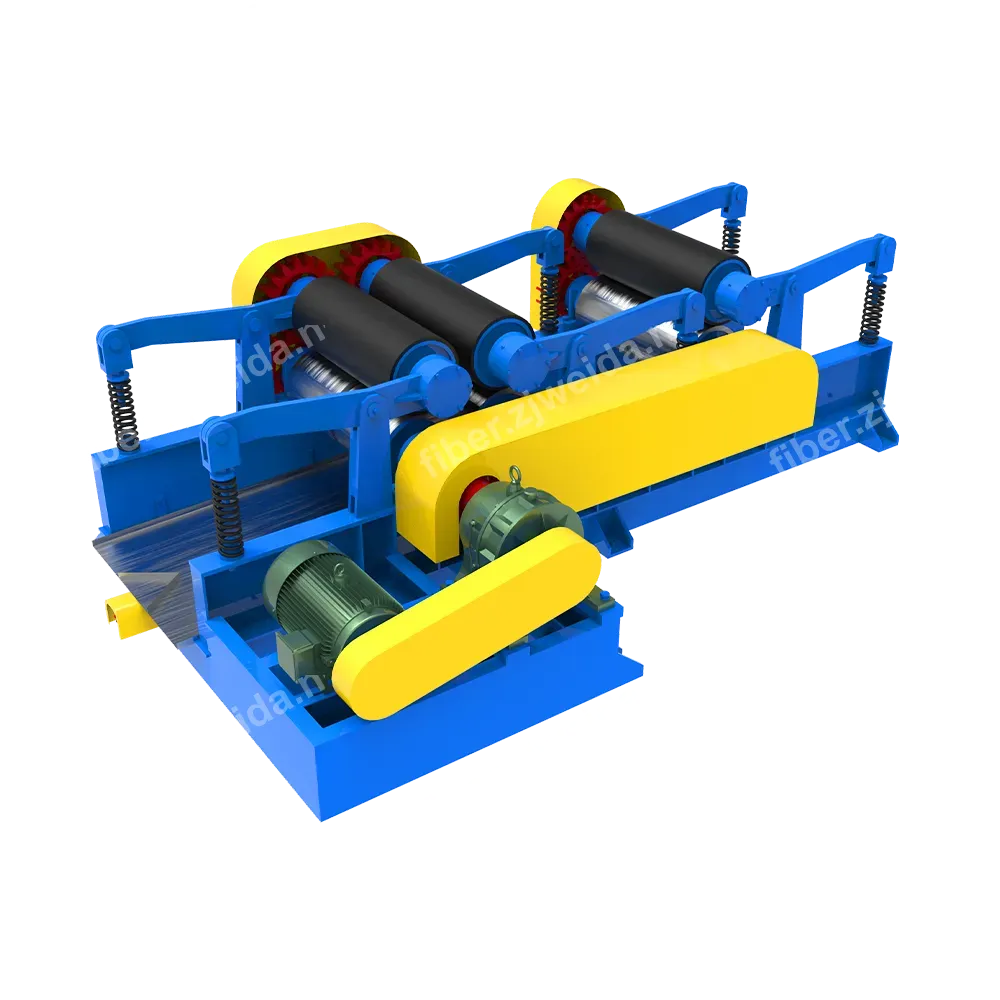

Dewatering Machine

Powerful three-stage squeezing, deep dewatering, accelerating fiber drying, suitable for various high-moisture plant fibers.

Key Highlights:

- 3-Stage Dewatering: Three sets of rollers squeeze progressively, offering far better results than single-stage equipment.

- Elastic Tensioning: Large wire diameter springs automatically adjust pressure for smooth feeding without jamming.

- High Versatility: Suitable for Sisal, Jute, Banana, and other long fibers.

- Robust Structure: Large channel steel frame ensures smooth operation and low failure rates.

Product Overview

The YSJ6-32 Fiber Dewatering Machine is continuous mechanical dewatering equipment designed for high-moisture plant fibers. After washing or extraction, fibers hold significant water. This machine forcibly squeezes out free water via physical rolling. As a key pre-treatment before drying, it quickly reduces moisture content to below 20%, drastically cutting energy costs for hot air drying or time for sun drying.

Why Choose Us

Three-Stage Progressive Squeezing

Equipped with three pairs of 320mm diameter rollers, fibers undergo three continuous squeezes. Compared to ordinary single or double roller machines, dewatering is more thorough.

Adaptive Elastic Adjustment

Rollers feature elastic tensioning mechanisms that automatically adjust gap and pressure based on fiber layer thickness. This ensures sufficient squeezing force while preventing jamming due to uneven feeding.

Efficient Continuous Operation

Works with conveyor chains for automatic feeding, seamlessly docking with upstream washing equipment for continuous production up to 4 tons/hour.

Simple Maintenance

Intuitive design with few wear parts. Low roller speed (44rpm) means low wear and low noise.

Process Flow

- 1.Feeding: Place wet fibers on the conveyor chain.

- 2.1st Stage Squeezing: Enters first pair of rollers, removing most surface water.

- 3.2nd Stage Squeezing: Enters second pair for deeper squeezing.

- 4.3rd Stage Squeezing: Enters third pair for powerful residual water removal.

- 5.Discharge: Semi-dry fibers are discharged for drying.

Main Components

- Pressing Rollers (3 pairs)

- Conveyor Chain

- Spring Tensioner

- Frame & Drive

Application Scenarios

Large Fiber Factories

Pre-equipment for dryers to save energy.

Rainy Region Processing

Reducing reliance on sun drying weather.

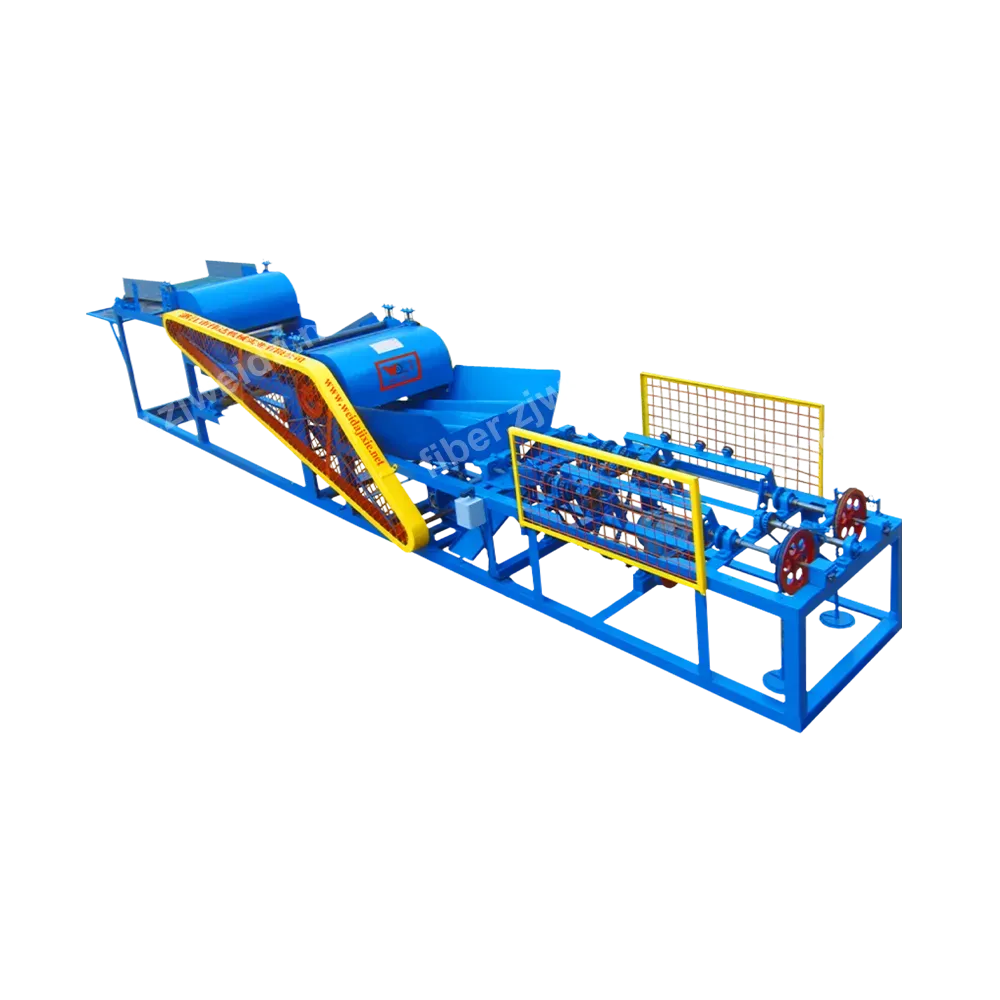

Recommended Matching Equipment

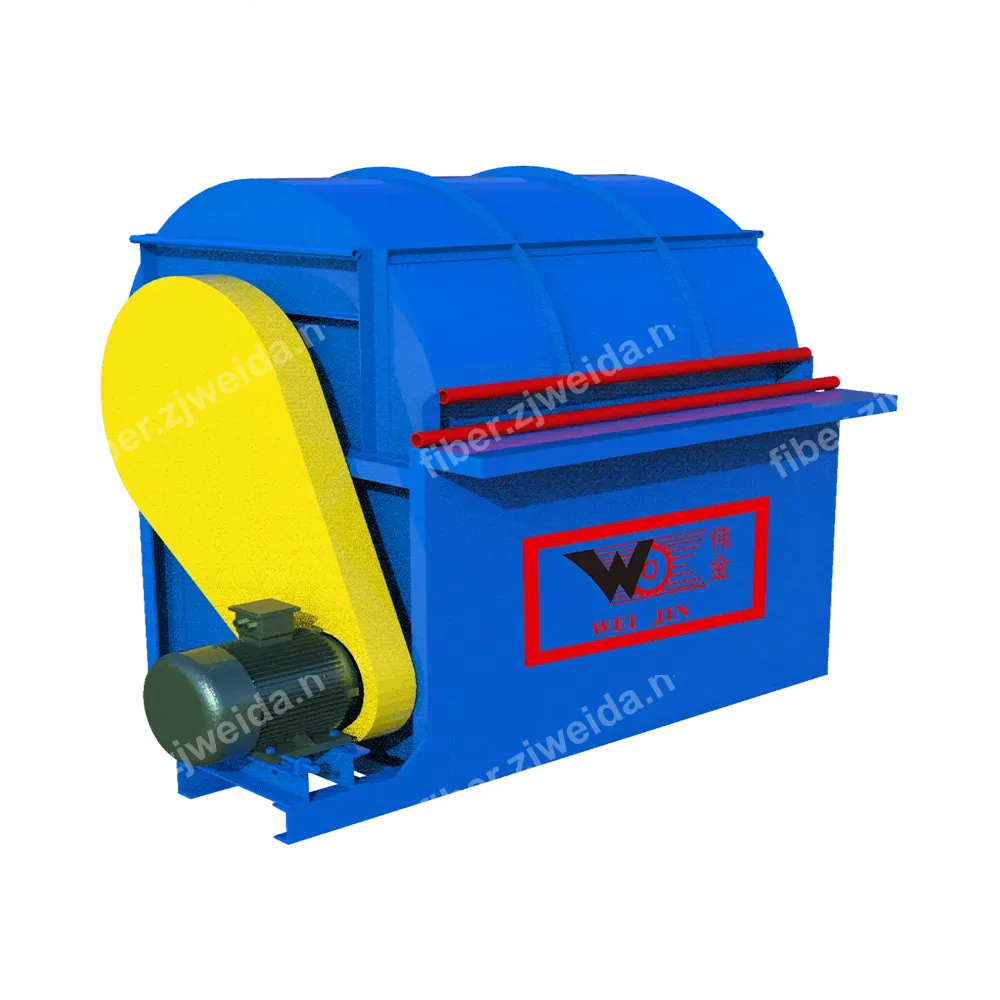

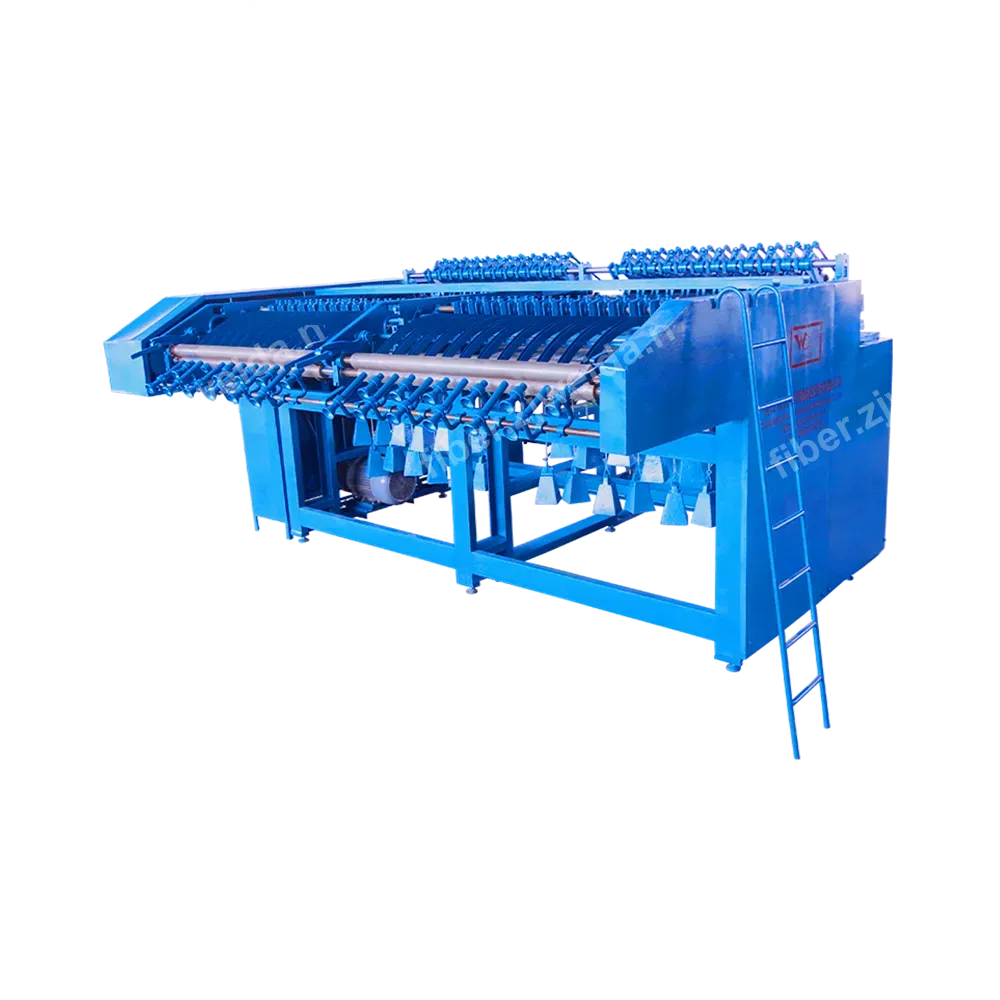

Fiber Extraction Machine

Upstream equipment.

Dryer/Drying Field

Downstream process.

| Model | YSJ6-32 |

| Raw Materials | Various Wet Plant Fibers |

| Capacity | 4 tons/hour (Fiber) |

| Moisture After Dewatering | ≤20% |

| Roller Diameter | 320 mm |

| Power | 11 kW |