Call Us

Fiber Baling Machine

Powerful hydraulic compression, neat and compact bales, significantly reducing long-distance transportation costs.

Key Highlights:

- Ultra-High Pressure: 100-200 tons hydraulic force ensures high density and small volume of fiber bales.

- Safe & Reliable: Equipped with safety doors and explosion-proof oil circuits to ensure operator safety.

- Easy Operation: Centralized control system, one-touch lifting, high baling efficiency.

- Customizable: Bale size can be customized according to container dimensions to optimize loading capacity.

Product Overview

The XDB Series Fiber Baling Machine is developed by Weida Machinery to solve the problems of difficult storage and high transportation costs for fluffy plant fibers (such as sisal, jute, coir, etc.). Utilizing the immense pressure generated by a high-performance hydraulic system, it compresses loose dry fibers into high-density rectangular bales. The volume of baled fibers can be reduced by 5-8 times, making them neat, beautiful, and easy to stack and transport in containers. It is standard configuration for export-oriented fiber processing plants.

Why Choose Us

Vertical Structure, Small Footprint

Designed with a vertical hydraulic cylinder, the compact structure occupies less floor space compared to horizontal balers, suitable for various factory layouts.

Stable Hydraulic System

Uses high-quality hydraulic pump stations and cylinders. Oil circuit joints use a cone sealing design without washers, completely eliminating oil leakage risks. Pressure remains stable, ensuring consistent weight and size for every bale.

User-Friendly Operation

Equipped with an independent control box, operation is simple and intuitive. The baling box has a door opening mechanism for easy removal of finished bales.

Safety Protection

Features safety interlocks; compression can only start when the safety door is closed, effectively preventing accidents.

Process Flow

- 1.Weighing & Feeding: Weigh a fixed amount of dry fiber and place it evenly into the baling box.

- 2.Compression: Activate the hydraulic cylinder; the press head descends to compact the fiber.

- 3.Strapping: Under pressure holding state, manually thread straps (wire or plastic) to bind the bale.

- 4.Ejection: The press head rises, box door opens, and the finished bale is ejected or manually removed.

Main Components

- Hydraulic Cylinder

- Hydraulic Station

- Frame & Baling Box

- Control System

Application Scenarios

Sisal/Jute Processing Plants

The final step before finished fibers enter the warehouse.

Waste Recycling

Also used for baling waste paper and cotton waste.

Recommended Matching Equipment

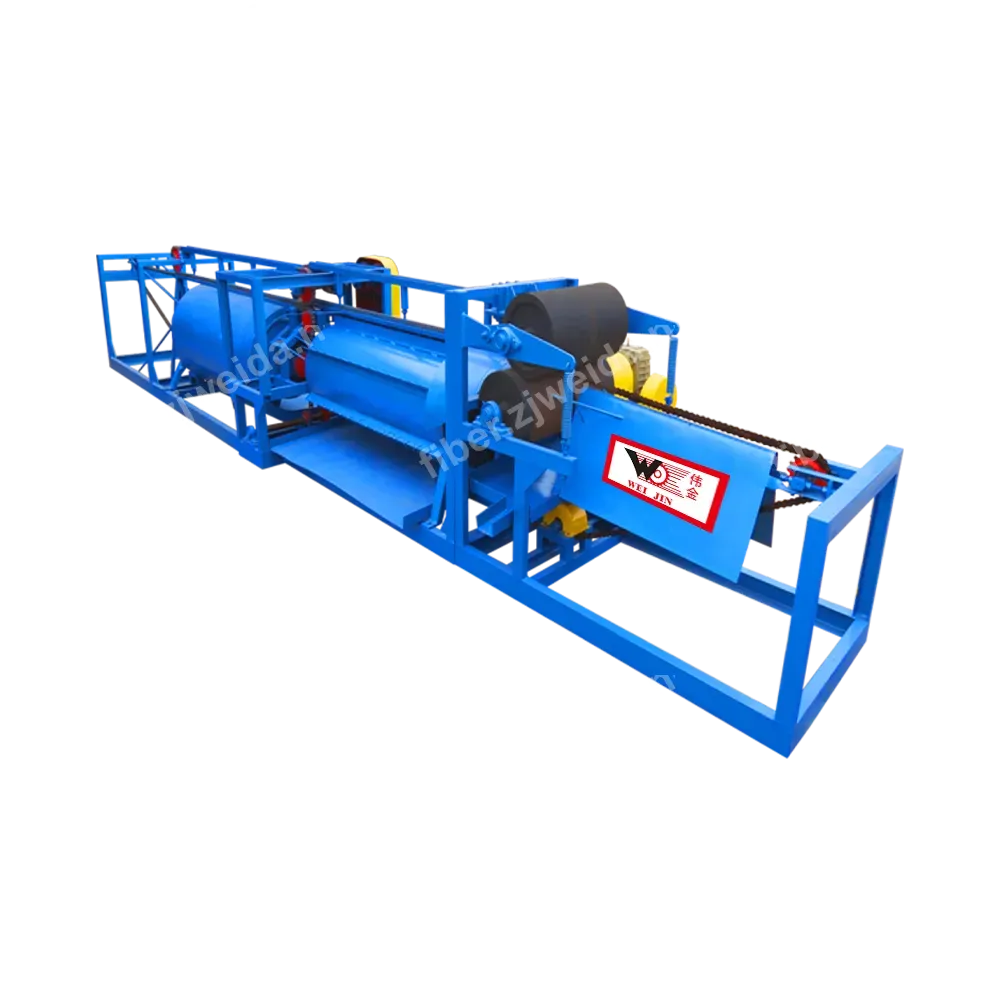

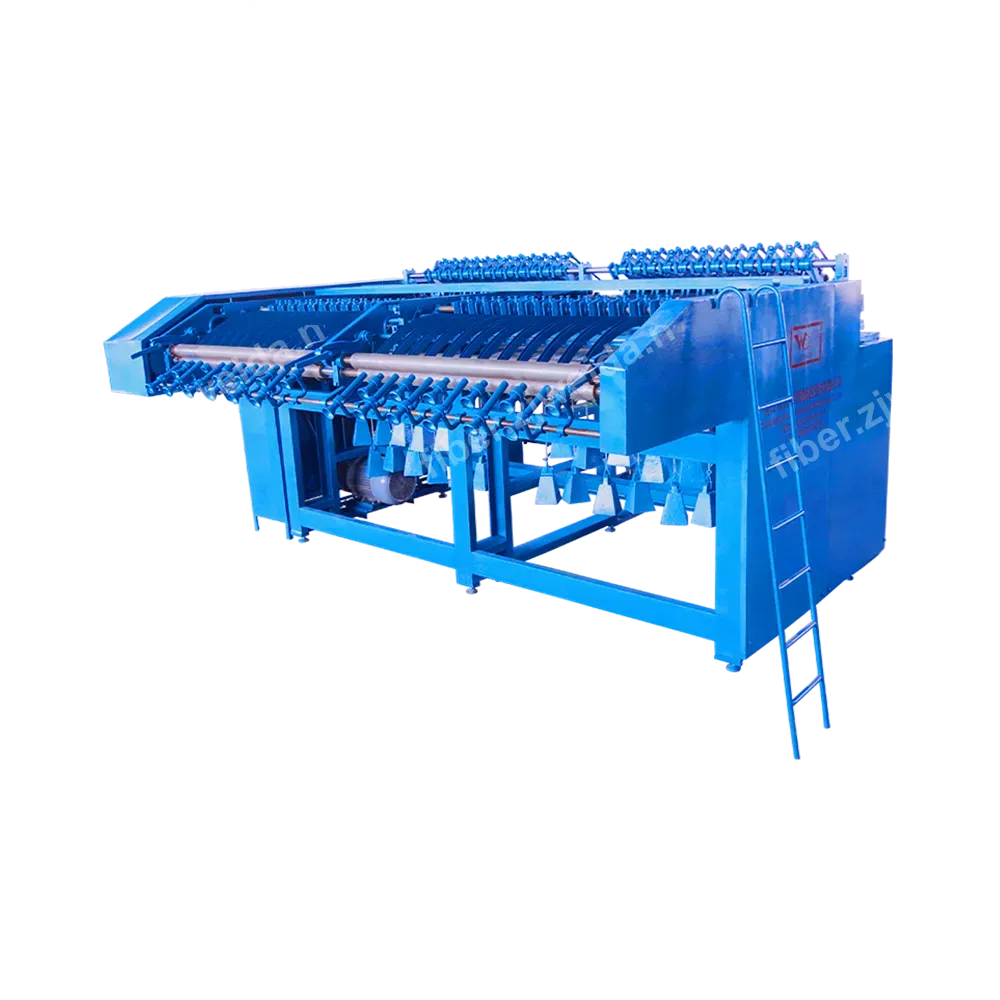

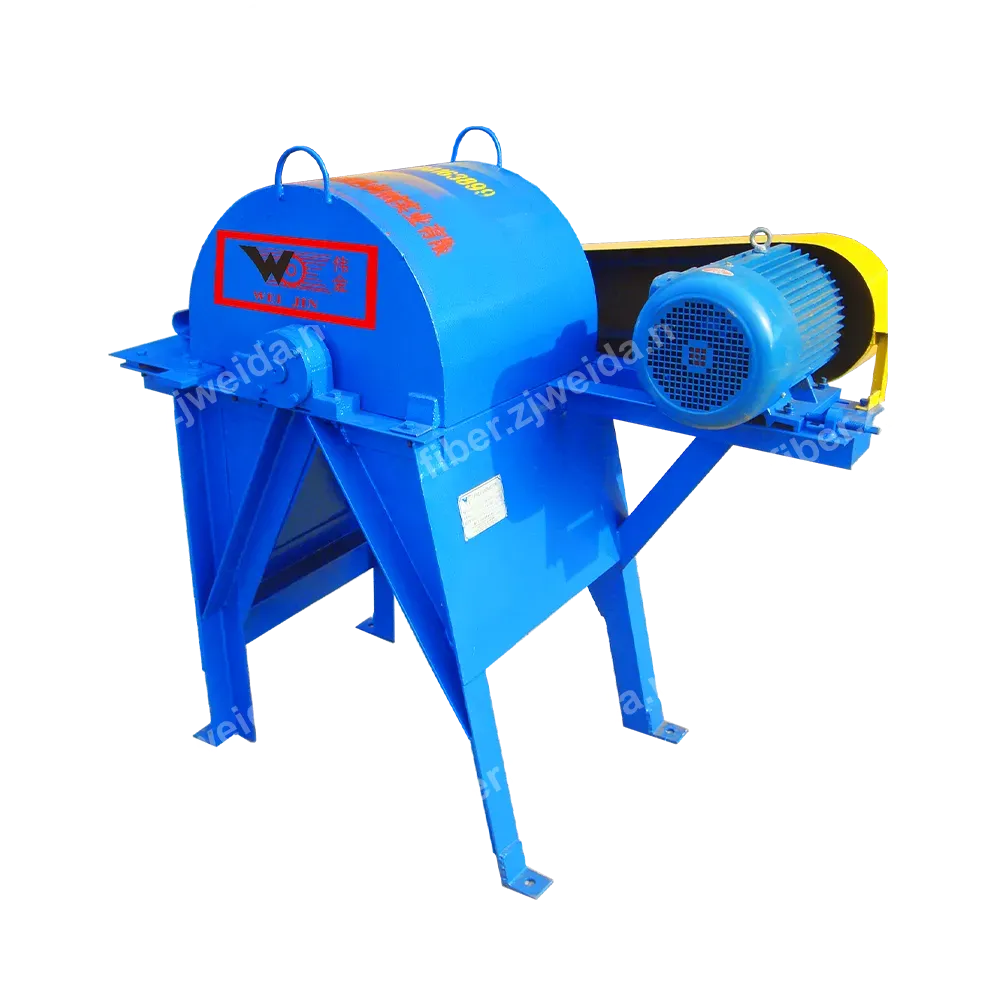

Fiber Cleaning Machine

Cleaning is usually required before baling.

Electronic Scale

For weighing feed material.

| Model | XDB-100 / XDB-120 / XDB-150 |

| Nominal Pressure | 100 - 200 Tons |

| Bale Weight | 100 - 250 kg/bale |

| Power | 18.5 kW - 30 kW |