Call Us

Banana Stem Automatic Fiber Extraction Line

Large-scale fiber extraction solution designed for banana plantations, solving the difficulty of processing thick and juicy stems with high efficiency.

Key Highlights:

- Optimized Design: Optimized for thick banana stems, preventing jamming and clogging.

- High Capacity: 5T/h massive processing capacity to meet the needs of large plantations.

- Flake Material Adaptation: Industry-leading efficiency for processing split banana stem flakes.

- Stable & Reliable: Continuous operation time ≥10000 hours, adapted to tropical production environments.

Product Overview

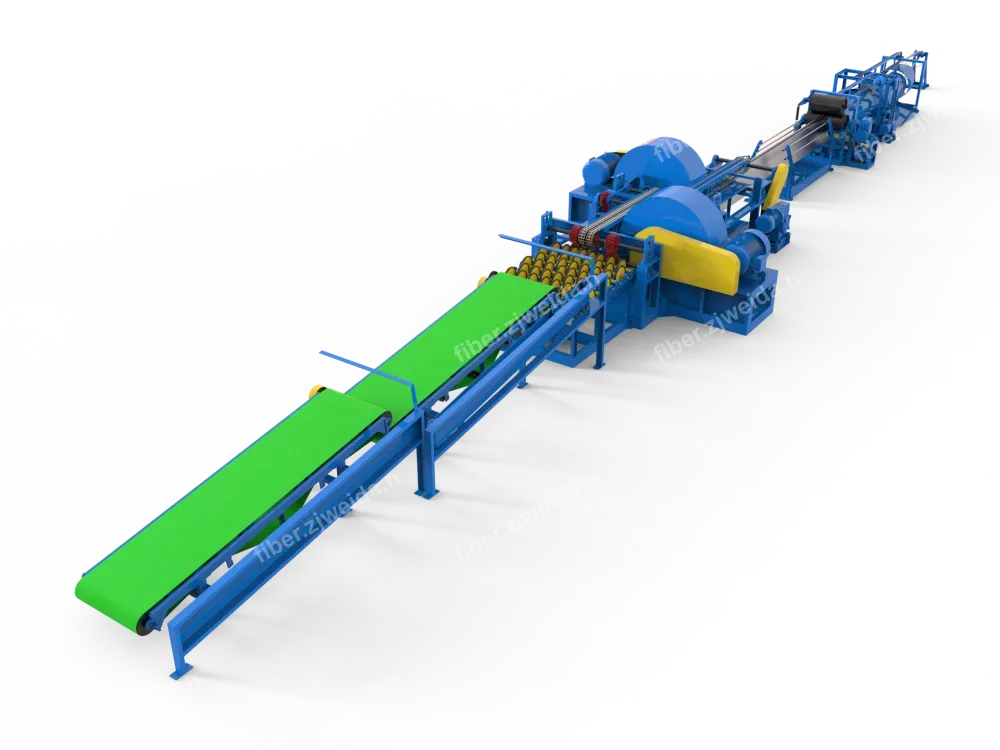

BGMX-1300 Banana Stem Automatic Fiber Extraction Line is a large-scale complete equipment set developed by Weida Machinery to address the issue of massive stem waste in the banana industry. Banana stems have high water content, large volume, and are difficult to extract fiber from. This production line combines front-end splitting pretreatment (accessory equipment) with core double-drum decortication technology to achieve fully automatic continuous processing from banana stems to clean fiber, representing a leading industrial solution for banana fiber.

Why Choose Us

Targeted Structure Optimization, Smooth Operation

Optimized feeding mechanism and decortication gap specifically for banana stems with thick fiber layers and extremely high water content, effectively preventing jamming and blockage during processing, ensuring smooth line operation.

Double-Drum Decortication, High Extraction Rate

The main machine adopts a double-drum structure combined with high-speed rotating curved blades, scraping the base first and then the tip. This progressive processing effectively separates pulp from fiber, achieving an extraction rate of 85-95%.

Integrated Washing & Dewatering, Quality Enhancement

Connected with a fiber dewatering and polishing machine at the rear. It performs water spraying cleaning and roller dewatering while extracting fiber, removing banana juice (containing sugar and gum), preventing fiber oxidation and discoloration, and producing clean, good-colored fiber.

High Automation, Labor Saving

Through dial conveying and swing arraying technology, automatic and orderly material entry is achieved. The core equipment of the entire line requires only 2-3 operators, significantly reducing labor intensity and costs.

Process Flow

- 1.Material Splitting: Banana stems are split into flakes by the Splitting Machine (XJPP Series).

- 2.Automatic Conveying: Flake materials are fed in via belt conveyor.

- 3.Automatic Arraying: Arraying mechanism organizes material orientation.

- 4.Double-Stage Decortication: First machine decorticates the base, second machine decorticates the tip.

- 5.Washing & Dewatering: Fiber enters the dewatering polishing machine for spray washing and squeeze dewatering.

- 6.Finished Output: Clean semi-dry banana fiber is output for manual collection.

Main Components

- Belt Conveyors

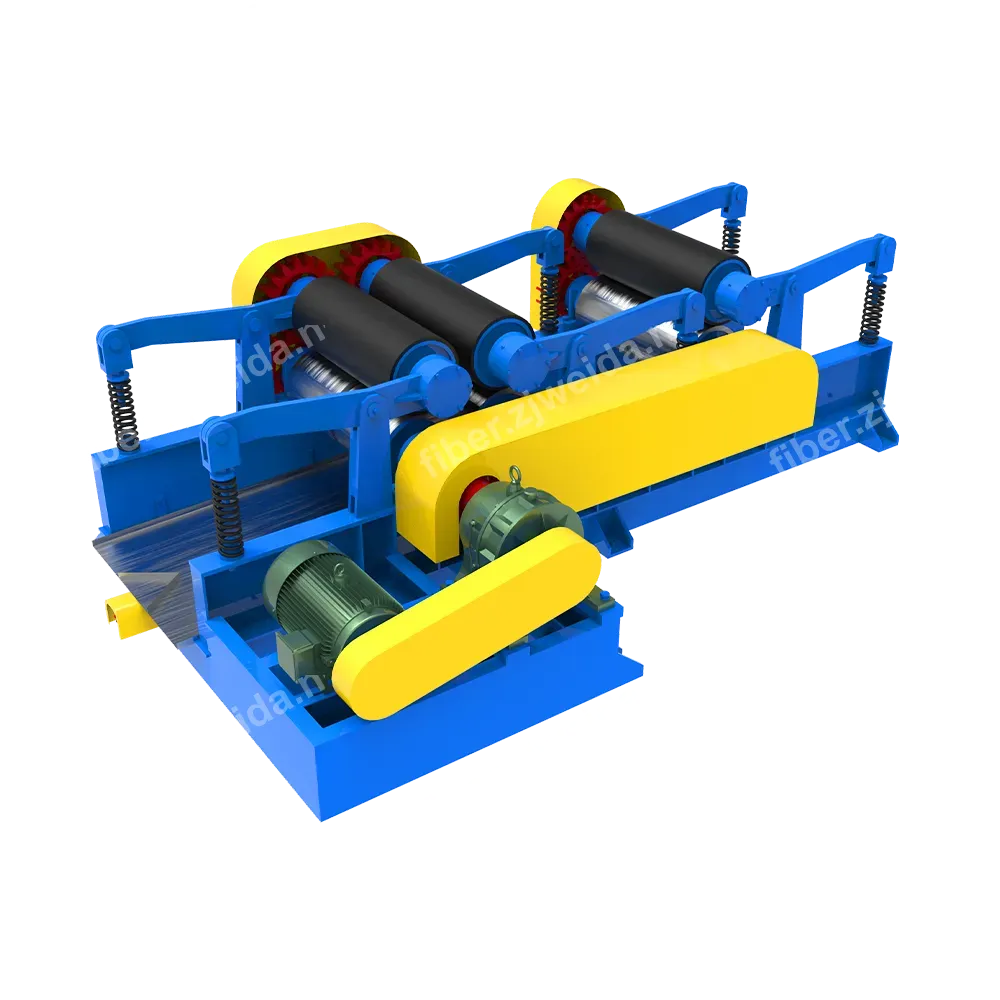

- Arraying Machine

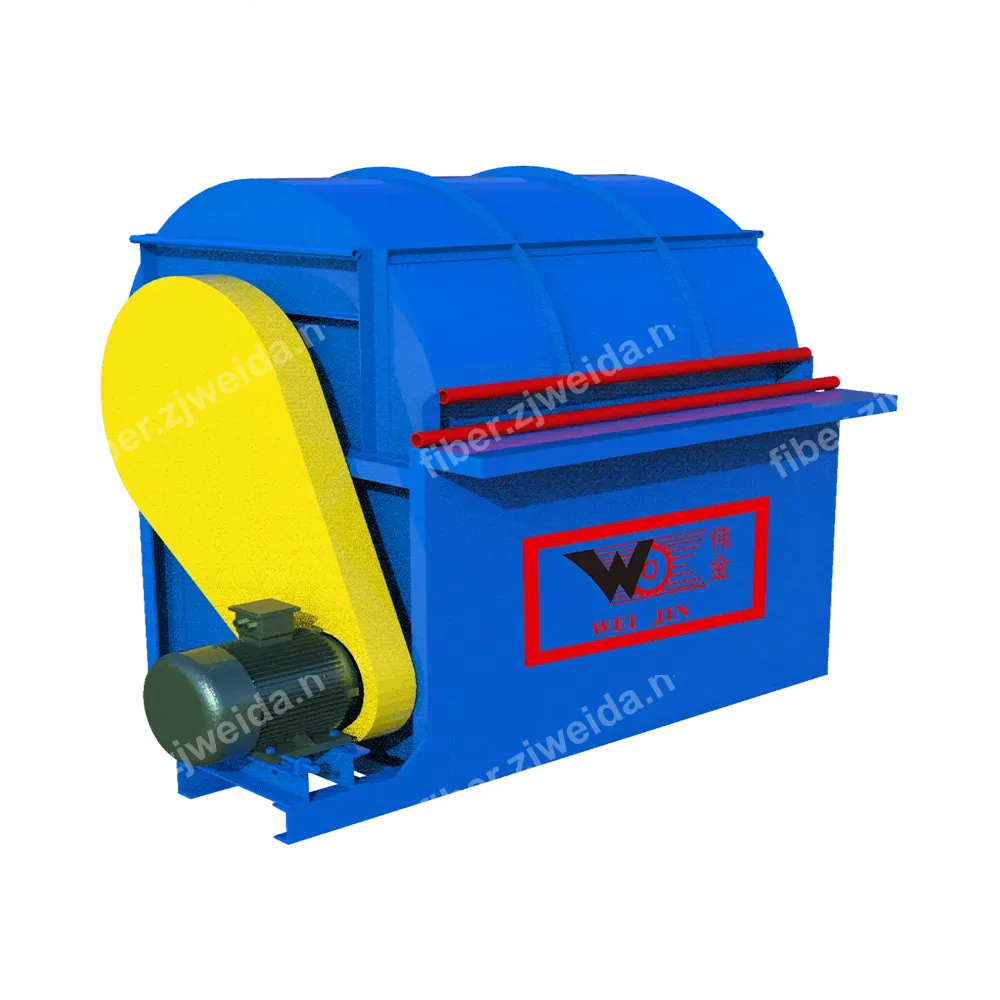

- Double-Drum Extraction Machine

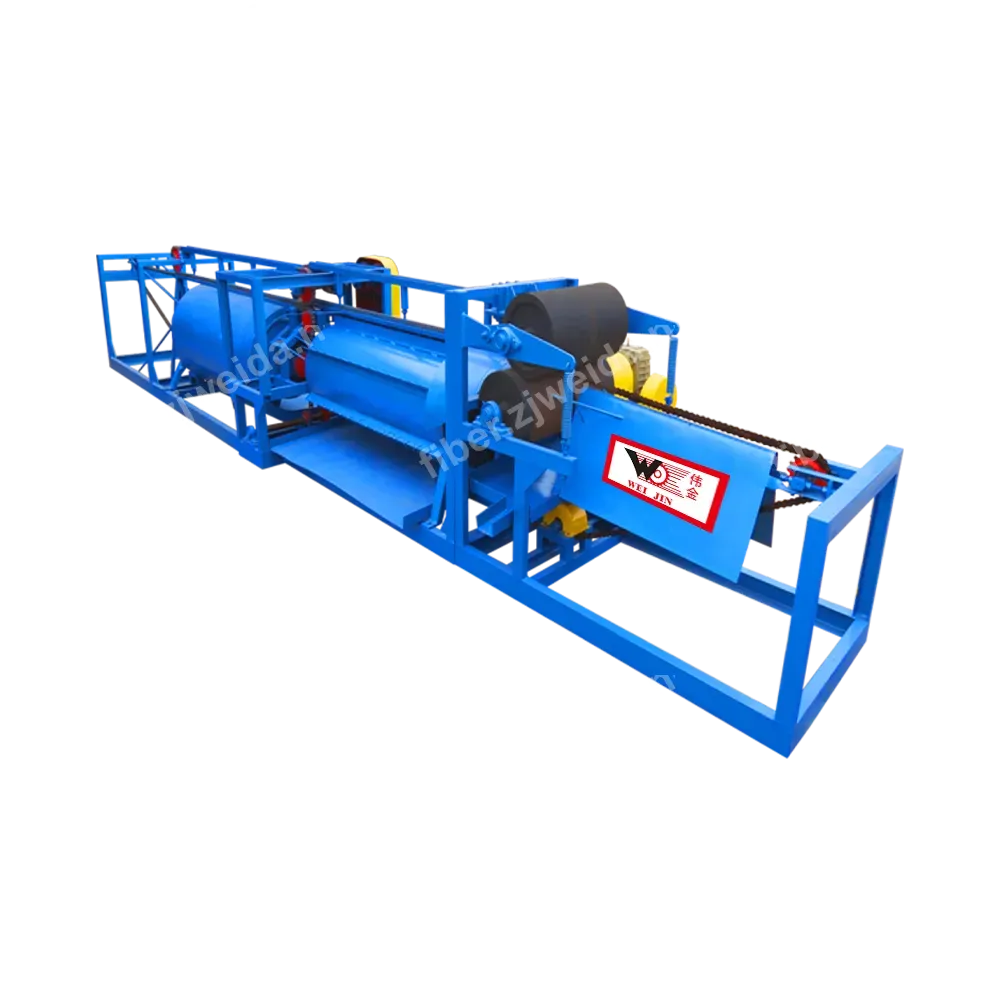

- Fiber Dewatering & Polishing Machine

- Control Box

Application Scenarios

Large Banana Plantations

Suitable for concentrated banana growing areas, solving stem disposal problems.

Abaca Plantations

Suitable for large-scale extraction of Manila Hemp.

Biomass Resource Projects

Converting banana stems into fiber resources.

Recommended Matching Equipment

Banana Stem Splitter (XJPP Series)

Essential equipment for longitudinally splitting thick banana stems to facilitate subsequent extraction.

Waste Juice Extractor (JZ Series)

Dewatering the scraped flesh residue to recover potassium-rich banana juice (high-quality liquid fertilizer).

Fiber Baling Machine (XDB-120)

Used for baling finished fiber.

| Model | BGMX-1300 |

| Raw Material | Banana Stem / Abaca |

| Design Capacity | 5 T/h (Raw Material Processing) |

| Extraction Rate | 85-95% |

| Power | 81.35 kW |

| Dimensions | Approx 20.3m × 4m × 1.6m |

| Total Weight | Approx 10 Tons |