Call Us

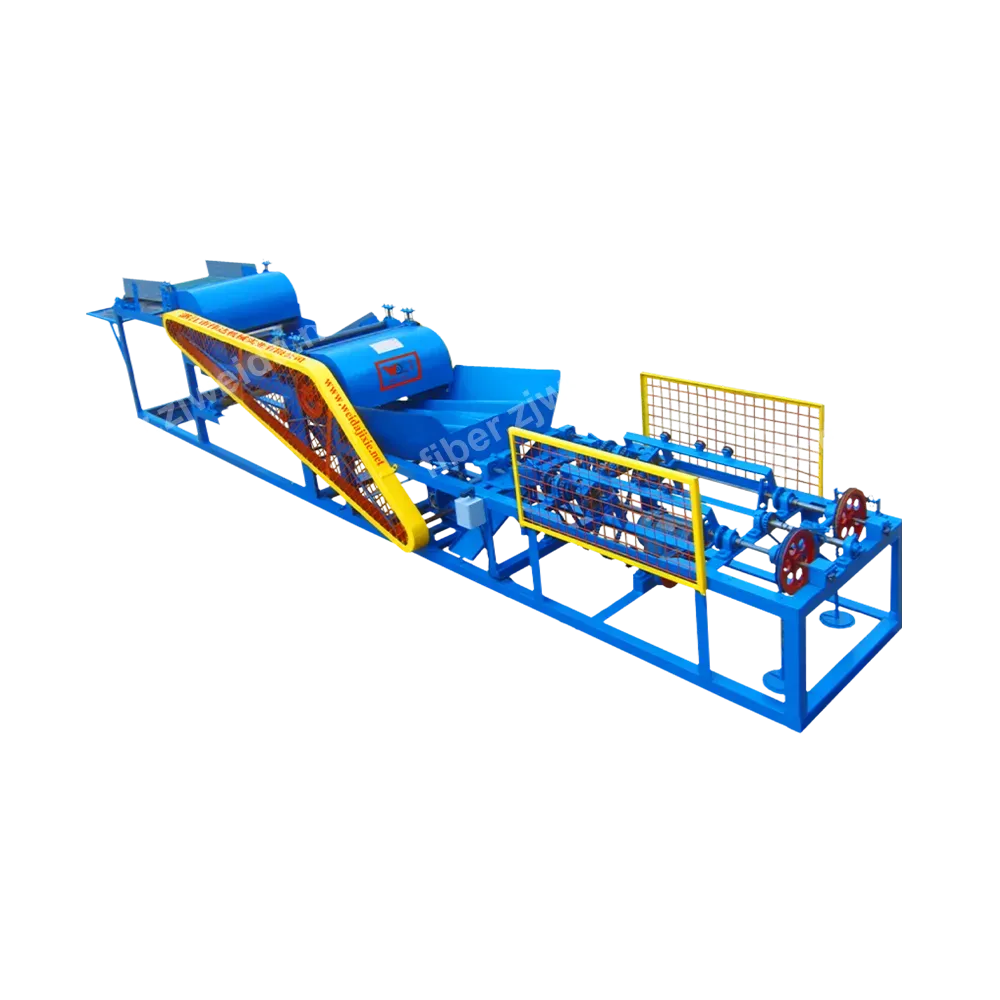

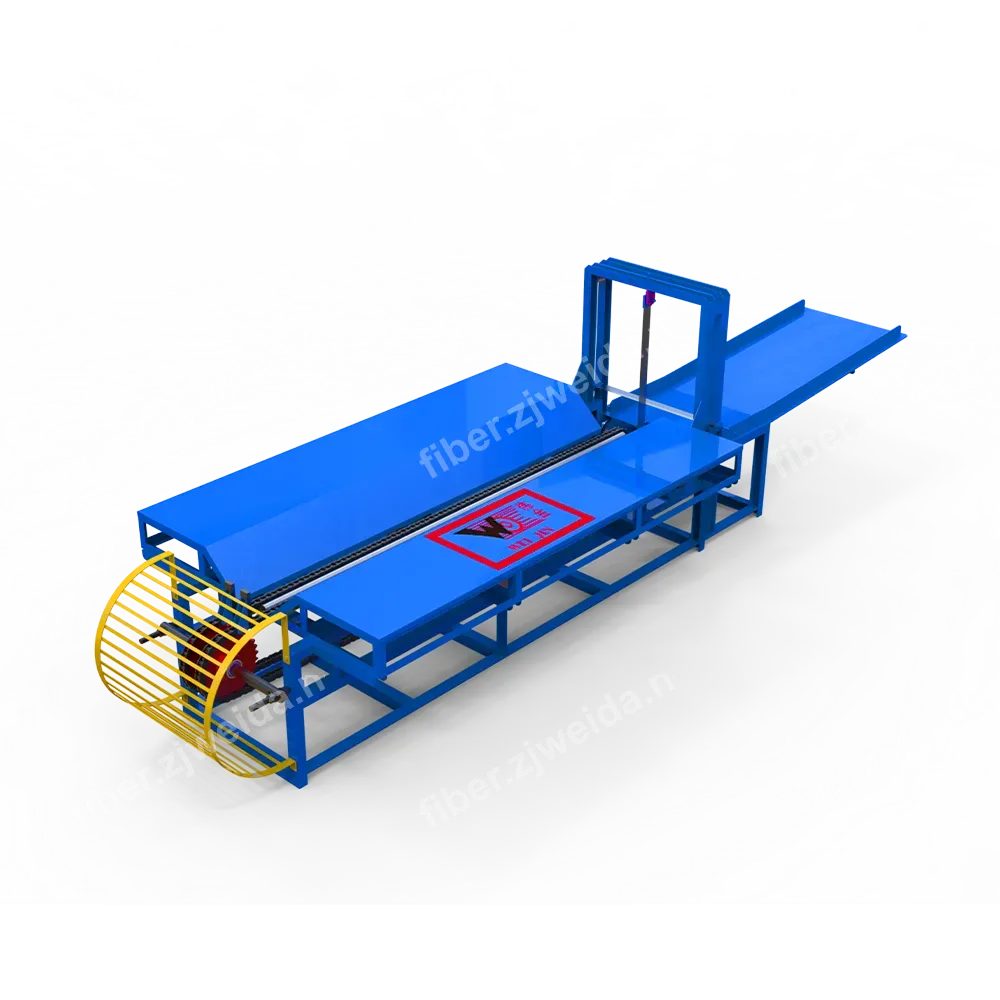

Banana Stem Chipping Machine

Replaces manual splitting, increasing efficiency by 20 times, providing standardized flake raw materials for banana fiber extraction.

Key Highlights:

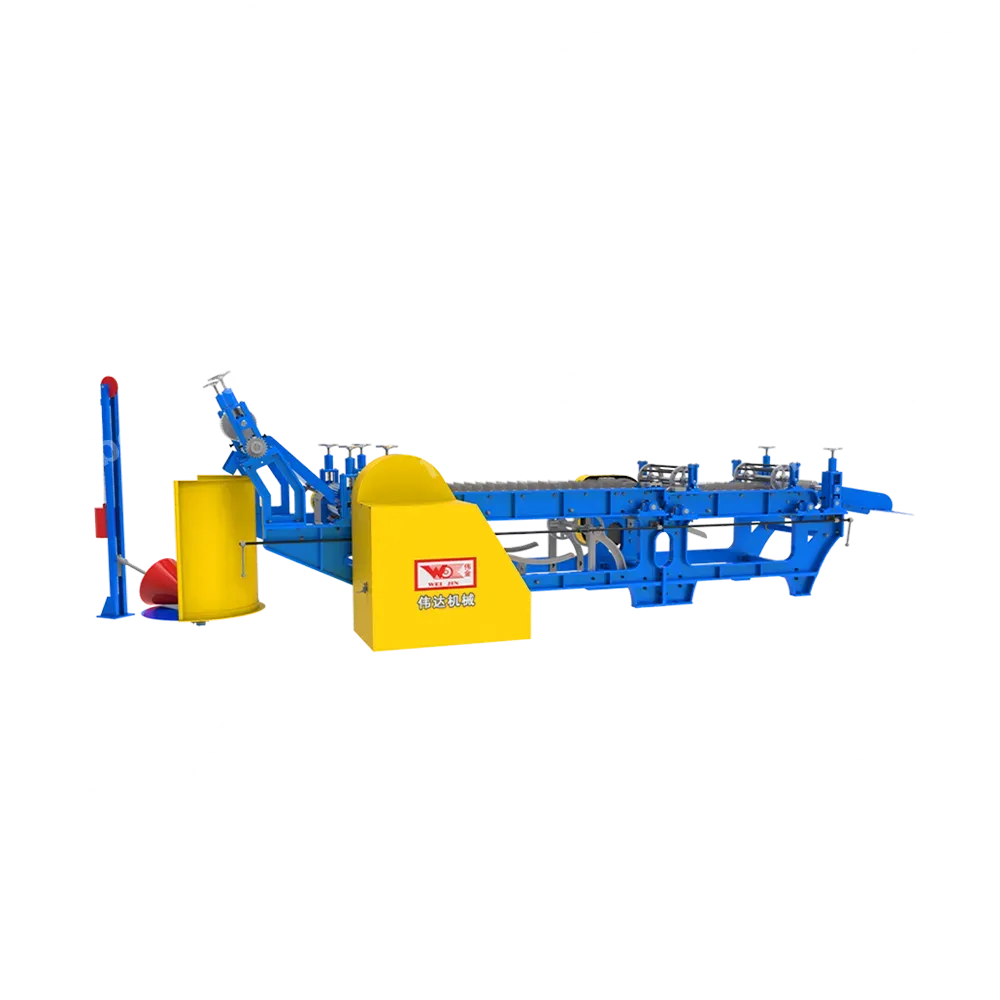

- High-Speed Chipping: Chain propulsion splits the entire stem into 4 (or 2) pieces in one go, with a capacity of up to 5 tons/hour.

- Simple Operation: Only requires manual placement; the machine automatically feeds and cuts, ensuring safety and ease.

- Uniform Cutting: Longitudinal cutting is even, facilitating subsequent feeding and extraction in the decorticator.

- Easy Mobility: Compact structure with wheels (on some models) for easy movement in banana plantations.

Product Overview

Banana stems are thick, high in moisture, and structurally dense. Feeding them directly into a decorticator is inefficient and can cause blockages. The XJPP Series Banana Stem Chipping Machine is designed to solve this problem. It uses mechanical power to replace traditional manual chopping, quickly and evenly splitting thick banana trunks into flakes suitable for extraction machines. It is an indispensable first step in the banana fiber processing line.

Why Choose Us

Efficiency Far Beyond Manual Labor

Manual splitting is labor-intensive and inefficient. This machine, driven by a motor and chain propulsion with vertical and horizontal blades, completes chipping in one pass. A single machine increases efficiency by over 20 times compared to manual methods.

Standardized Process

Manually split stems vary in width, affecting fiber yield. Machine chipping ensures uniform size, providing standardized raw materials for subsequent fiber extraction, improving overall yield and quality.

High Safety

Operators only need to place stems into the feeding trough without manual pushing, keeping hands away from blades and significantly reducing risks.

Energy Saving & Durable

Low power consumption (1.5-3kW). Blades are made of special steel, sharp and durable.

Process Flow

- 1.Cutting: Cut long banana trunks into segments of about 1.5 meters.

- 2.Manual Loading: Place trunks flat into the feeding trough of the chipping machine.

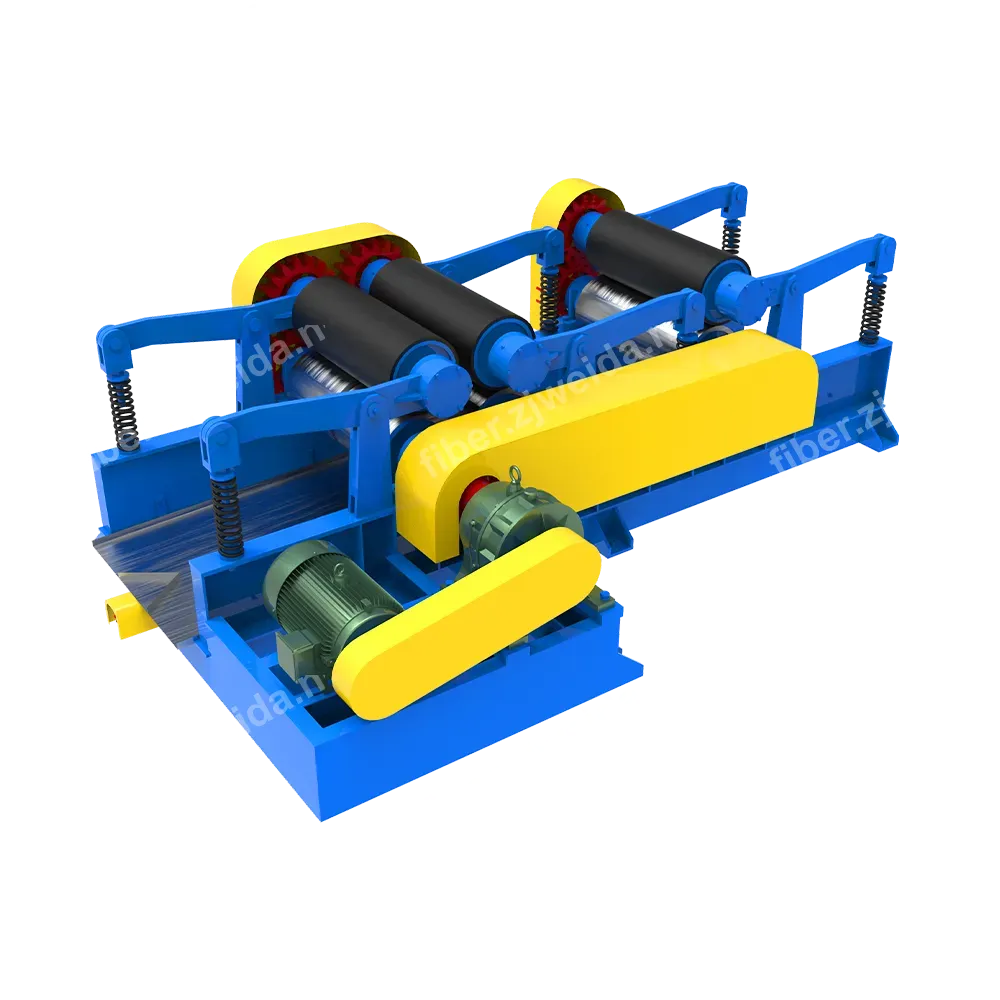

- 3.Automatic Feeding: Chain pushers move the trunk forward.

- 4.Cross Cutting: Trunks pass through cross blades and are split longitudinally.

- 5.Discharge: Flaked stems fall out for collection or conveyance to the next process.

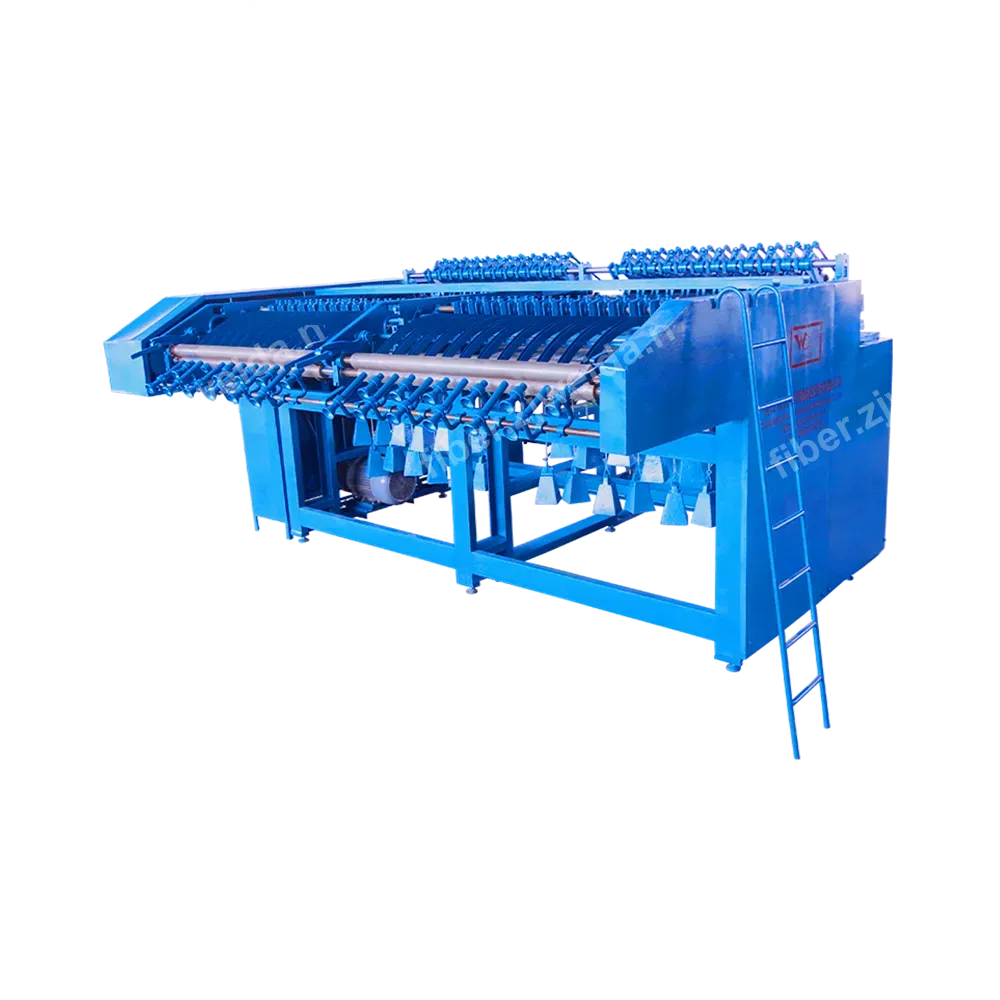

Main Components

- Chain Propulsion Device

- Cutting Blades

- Guide Trough

- Motor

Application Scenarios

Banana Fiber Extraction Line

Essential pre-process step.

Banana Stem Crushing

Easier to crush after chipping for returning to the field.

Recommended Matching Equipment

Banana Fiber Extraction Machine (BGMX/ZGM Series)

Chipped raw materials are fed directly into the extraction machine.

| Model | XJPP-2900 / XJPP-2900A |

| Capacity | 3 - 5 tons/hour |

| Blade Length | 305 mm / 550 mm |

| Power | 1.5 kW - 3 kW |

| Weight | 280 kg - 430 kg |