Call Us

ZHANJIANG WEIDA

MACHINERY MANUFACTURER

Who We Are: Our Identity

Zhanjiang Weida Machinery Industrial Co., Ltd. (Brand: "WEIJIN"), founded in 2004, is a veteran manufacturing enterprise deeply rooted in the plant fiber processing field for over 20 years. We focus on the R&D and manufacturing of primary processing extraction and deep processing equipment for tropical and subtropical plant fibers, being an important player in China and even the global natural bast and leaf fiber primary processing equipment field.

With excellent quality and service, our business footprint has extended from China to core tropical crop production regions in Southeast Asia, Africa, and Latin America, winning widespread market recognition and stable customer trust.

Since 2004

Brand: WEIJIN

Global Vision

Veteran Manufacturer

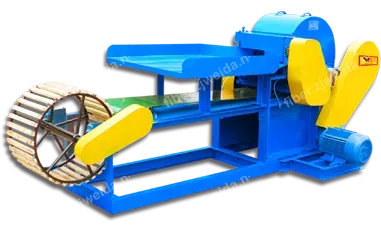

Core Business: Full Category Coverage

We are committed to providing global customers with efficient, stable, and eco-friendly one-stop plant fiber processing solutions.

Wide Material Applicability: Covering natural plant fibers such as Sisal, Jute, Pineapple Leaf, Banana Stem, extending to Palm, Coir, and composite fiber recycling.

Full Industry Chain Equipment: From plant fiber extraction, cleaning, baling, to short fiber rope making, spinning, and residue treatment, providing complete production line equipment.

Wide Materials

Full Chain

One-Stop

Efficient & Eco

Core Advantages: Professional Quality

Combining market pain points with innovation needs, Weida Machinery has built a competitive core value system:

Multi-dimensional Matrix: Meeting production needs of different scales (Mobile/Economic/Automated).

Value Loop: Promoting green processing, turning waste into treasure (Residue/Short Fiber Reuse).

Solid Workmanship: Fearless of high heat and humidity, ensuring continuous production in tropical environments.

Multi-Matrix

Value Loop

Solid Build

Env. Adapted

Future R&D: Exploring Tomorrow

We do not stop at the present, but focus on future fiber application exploration:

Fiber Application Lab: Conducting Mulberry Branch fiber extraction experiments to expand fiber sources.

Process Upgrade: Promoting Forage and Plant Dewatering process upgrades, providing new ideas for agricultural deep processing.

Fiber Lab

Mulberry Ext.

Dewatering

Exploration

20+

Years

Experience

Innovating Plant Fiber

Processing Technology.

Weida Machinery Since 2004

Mr. Lai Weiping

Founder of Weida Machinery · Pioneer of Tropical Fiber Processing Equipment

Rooted in the Land, Defining the Industry

Born on a tropical farm and growing up amidst the roar of machinery, Mr. Lai Weiping has pursued engineering practice and technological innovation relentlessly. With a passion for machinery, he has dedicated over 30 years to the field of plant fiber processing equipment, becoming a leader in mechanical design and R&D with profound industry experience. He integrates his deep understanding of fiber characteristics into equipment innovation, committed to providing practical solutions for the mechanization of global tropical agriculture.

The Path of Technical Authority

- Innovator of Leaf Fiber Extraction Technology: Promoted the iterative upgrade of multiple generations of sisal processing equipment, setting new standards for the extraction efficiency and quality of modern leaf fibers.

- Practitioner of Pineapple Fiber Equipment: Successfully developed pineapple fiber extraction equipment and applied it in domestic and international production, facilitating the large-scale production of pineapple fibers.

- Explorer of Comprehensive Utilization of Sisal Residue: Pioneered the sisal residue juicer, effectively solving the traditional problem of sisal residue dewatering and improving resource utilization efficiency.

Jacy Lee

Senior Expert in Weida Plant Fiber Equipment:

18 Years in the Industry, Empowering Global Clients with Professionalism and Warmth

Since joining Weida in 2006, Jacy has always upheld the philosophy that "customer success is our success," transforming deep technical knowledge and global service experience into tangible value. She excels at translating equipment parameters and technical logic into clear, understandable scenario-based solutions, combining customer production processes with raw material characteristics to provide precise, actionable custom recommendations that truly fit business needs.

As a core driver of international business, she led the construction of a global service network covering Southeast Asia, Africa, South America, Europe, and Australia, leading the team to continuous performance breakthroughs. Facing cross-time-zone collaboration, she ensures timely responses with efficient and flexible communication mechanisms; when encountering technical issues, she quickly coordinates with the after-sales team to provide professional support, following up until the customer is satisfied. She advocates "full-process companion service" — from demand insight to stable equipment production, carefully guarding every link to make cooperation worry-free and reassuring.

In the team, she focuses on professional empowerment and service details, leading team growth with high standards; in the hearts of customers, she wins widespread trust with sincerity, reliability, and deep empathy. Because of this consistent professional dedication, industry colleagues often say: "In the field of plant fiber equipment, Weida Jacy is a trustworthy expert partner."

She believes: True professionalism stems from a deep understanding of customer needs and is achieved through actions that continuously create value.

Development History

Development History

Quality Improvement, Product Upgrade

Since 2004, Weida Machinery has focused on plant fiber processing equipment. With over 20 years of intensive cultivation, we have achieved the leap from "following" to "leading".

01

Foundation Phase (2004-2010)

Anchoring the Track, Breaking Through Basics

Addressing the pain points of low industry efficiency and high loss, we successfully developed the first-generation plant fiber extraction and cleaning machine. Equipment efficiency increased by 30%, loss reduced to below 15%, and by solving the problem of "acclimatization" of imported equipment through localization adaptation, established the prototype of industry standards.

02

Growth Breakthrough (2011-2018)

Perfecting Matrix, Multi-adaptation

Constructed the "extraction-combing-processing-baling" full-process production line and launched high-precision dewatering and polishing integrated machine. Breaking through the limitation of single material, achieved efficient processing of multiple categories of fibers such as pineapple leaf, banana stem, and coconut coir, transforming into a full-process solution service provider.

03

Leading Upgrade (2019-Present)

Green Intelligent Manufacturing, Global Layout

Closely following the trends of carbon peaking/neutrality and automation, the capacity of automatic fiber extraction machines doubled, and the double-roll decorticator set a new benchmark. Products are exported globally, deepening industry-university-research cooperation, continuously promoting the green and intelligent transformation of the industry, and leading the efficient utilization of global renewable resources.

Adhering to the original intention of quality for over 20 years, Weida Machinery will continue to break through and innovate in the field of plant fiber processing equipment, contributing to global green sustainable development.

20+

Founded in 2004

30+

CE CERTIFIED

100+

Countries Served

3000+

Cooperative Clients

Manufacturing System

Manufacturing System

Lean Manufacturing & Quality Control

Quality commitment spans the entire equipment lifecycle; we have built a long-term service-oriented manufacturing and quality management system.

Experienced Team · Experience Driven

Core process leaders have over 15 years of practical experience, deeply understanding materials and craftsmanship, ensuring precise execution of rigorous standards and laying a solid foundation for equipment quality.

Full Chain Traceability · Source Control

From core spindles to structural attachments, every component has a unique number traceable to the raw material batch. Through long-term data screening of high-quality supply chains, we ensure quality stability from the source.

Precision Craftsmanship · Physical Verification

Utilizing CNC machining centers and CNC lathes to ensure perfect realization of design performance, and applying advanced processes like laser welding to guarantee long-term structural stability and durability.

Lifetime Archives · Worry-free Service

A permanent technical archive is established for every machine, with drawings kept for over ten years. Exact parameters can be retrieved via part numbers, ensuring seamless matching for parts replacement and technical upgrades years later.

Strict comprehensive performance testing verification before delivery. From source traceability and precision manufacturing to long-term archive management, we solemnly promise: worry-free operation throughout the equipment lifecycle.